A kind of condensed ring compound and its preparation method and application

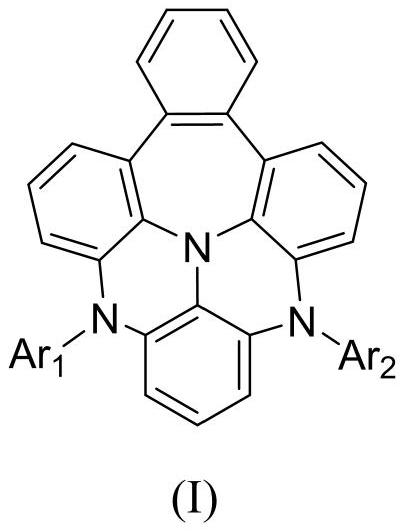

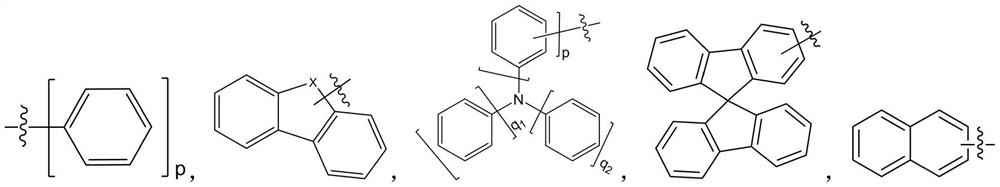

A compound and fused ring technology, applied in the field of fused ring compounds and their preparation, can solve the problems of inability to have both thermal stability and high triplet energy level, poor thermal stability, low glass transition temperature, etc., and reduce the potential barrier value. , Improve the effective transmission, increase the effect of effective injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

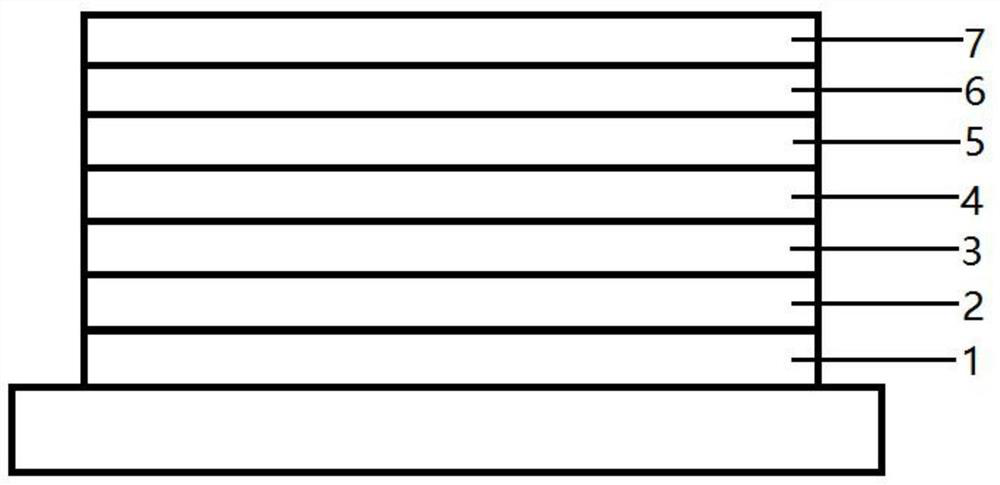

Image

Examples

Embodiment 1

[0050] This embodiment provides a condensed ring compound, which has the structure shown in the following formula C-1:

[0051]

[0052] The synthetic route of the compound shown in formula C-1 is as follows:

[0053]

[0054] The preparation method of the compound shown in formula C-1 specifically comprises the following steps:

[0055] (1) Preparation of intermediate (D)

[0056] Under nitrogen protection, in the four-necked flask of 500ml, add the compound shown in 24.3g (100mmol) formula (A) at room temperature, the compound shown in 24.7g (100mmol) formula (B), the toluene of 200ml, 19.2g ( 200mmol) sodium tert-butoxide, 91mg (0.1mmol) Pd 2 (dba)3, 0.6ml (0.3mmol) tri-tert-butylphosphine toluene solution (the mass fraction of tri-tert-butylphosphine in the tri-tert-butylphosphine toluene solution is 10%), after reflux reaction for 2 hours, add water to quench the reaction , the water phase was separated, and most of the solvent was removed by rotary evaporation, ...

Embodiment 2

[0063] This embodiment provides a condensed ring compound, which has the structure shown in the following formula C-2:

[0064]

[0065] The difference between the preparation steps of the compound shown in formula C-2 and the preparation steps of the compound shown in C-1 provided in Example 1 is only:

[0066] The compound represented by formula F-2 was used to replace the compound F-1 in step (3) of Example 1, and the yield was 85%.

[0067]

Embodiment 3

[0069] This embodiment provides a condensed ring compound, which has the structure shown in the following formula C-3:

[0070]

[0071] The difference between the preparation steps of the compound shown in formula C-3 and the preparation steps of the compound shown in C-1 provided in Example 1 is only:

[0072] The compound represented by formula F-3 was used to replace the compound F-1 in step (3) of Example 1, and the yield was 87%.

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com