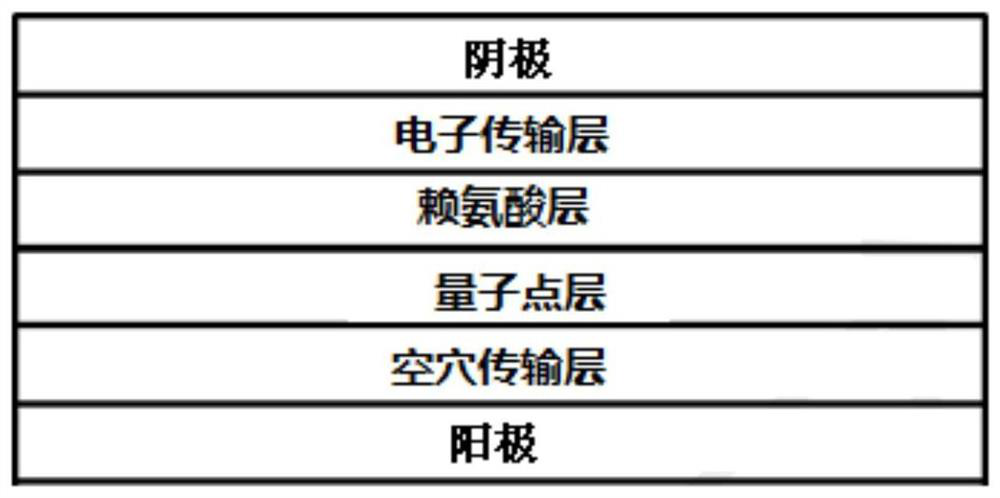

Quantum dot light emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as poor device performance, increased transmission difficulty, and energy level differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

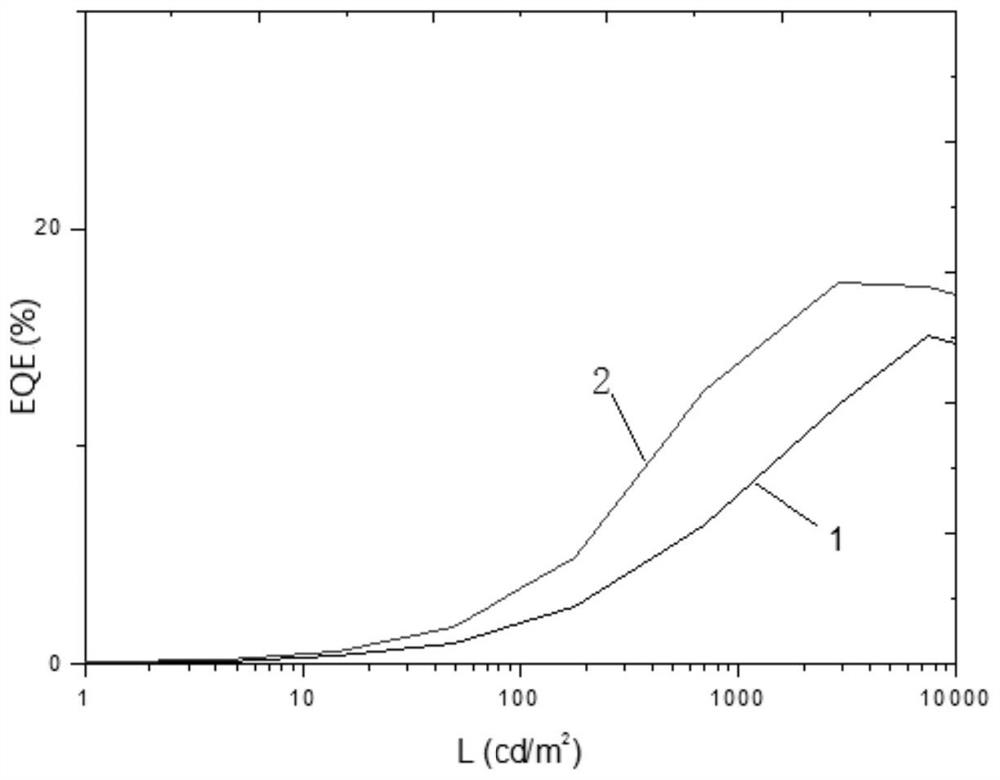

Examples

Embodiment 2

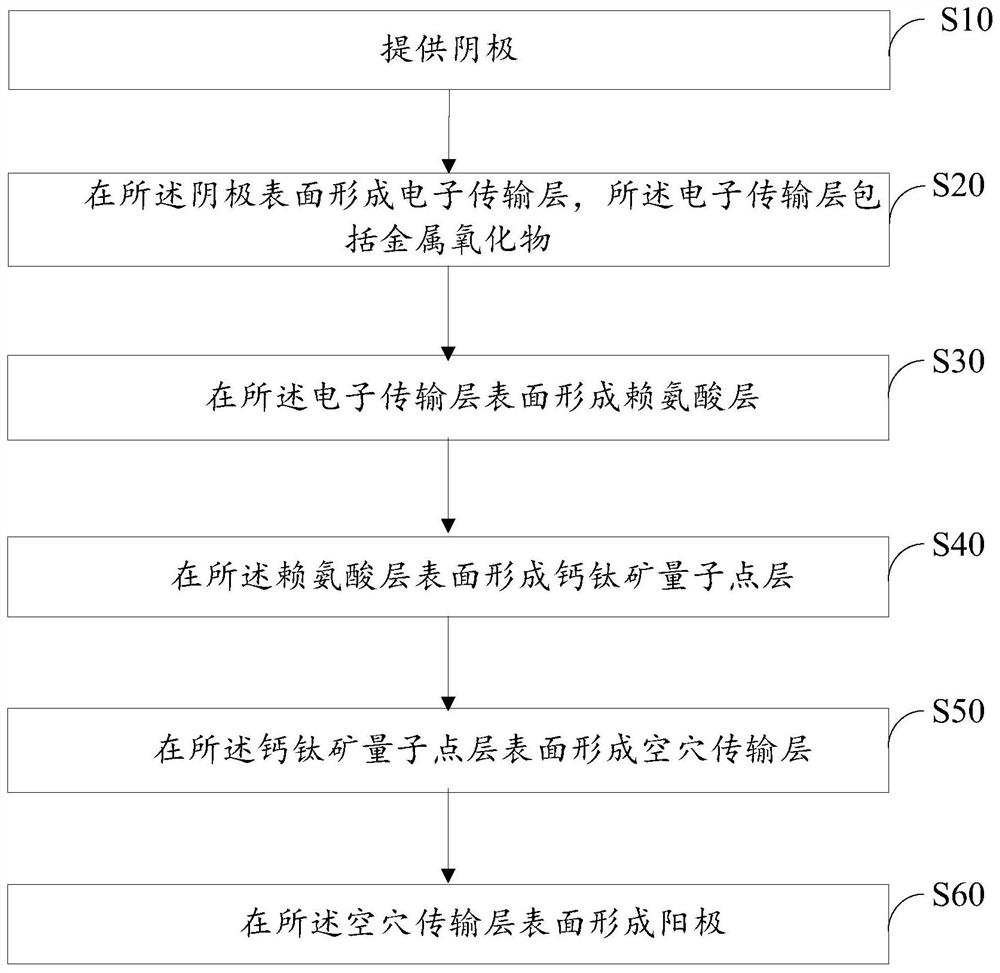

[0073] The preparation steps of the quantum dot light-emitting diode of the present embodiment are as follows:

[0074] 1) First clean the ITO glass, wipe the ITO surface with a cotton swab dipped in a small amount of soapy water to remove visible impurities on the surface, then ultrasonically clean with deionized water, acetone, ethanol, and isopropanol for 15 minutes, and then dry with nitrogen. stand-by.

[0075] 2), obtain solution A after mixing 5ml butyl titanate, 15ml ethanol and 2ml acetic acid, and obtain solution B after mixing 1ml water, 5ml ethanol and 0.1ml nitric acid; respectively, stir the two solutions of A and B for 2h, and make the solution Mix well; then slowly add solution B to solution A under stirring conditions, and stir for 1 h to obtain TiO 2 solution.

[0076] 3), suck 60 microliters of TFB toluene solution (concentration is 25mg / ml) with a pipette, drop it on the surface of the ITO glass, and then spin-coat at 3000rpm, the spin-coating time is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com