Thermoplastic modified polyethylene material for electric insulators, and preparation method thereof

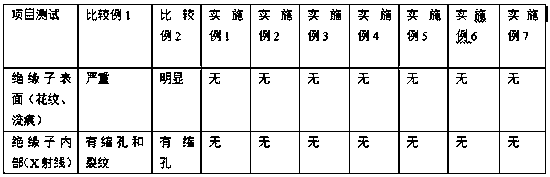

A technology for polyethylene and insulators, applied in the field of thermoplastic modified polyethylene materials and modified polyethylene materials, can solve the problems of new polyethylene insulators that have not been reported, and achieve less appearance and internal defects, low cost, and ensure weather resistance The effect of sexual demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A modified polyethylene material used for electric insulators, which is prepared from the following raw materials by weight percentage:

[0043] Polyethylene 56.5%

[0044] Inorganic filler 20%

[0045] Brominated flame retardant 18%

[0046] Synergistic flame retardant 5%

[0047] Stabilizer 0.5%

[0048] The polyethylene is high-density polyethylene (HDPE) with a melt index (230°C, 5kg) of 14g / 10min;

[0049] Described inorganic filler is modified calcium carbonate, and its particle diameter is 1250 orders;

[0050] Described brominated flame retardant is brominated epoxy;

[0051] The synergistic flame retardant is antimony trioxide;

[0052] Described stabilizer is made up of 0.1% antioxidant, 0.4% light stabilizer, wherein, antioxidant is compounded by antioxidant 1010 and antioxidant 168 by the ratio of 1:2; Light stabilizer is made of UV -531 (2-hydroxy-4-n-octyloxybenzophenone) and 770 (bis(2,2,6,6-tetramethylpiperidinyl) sebacate) in a ratio of 1:3 Matc...

Embodiment 2

[0055] A modified polyethylene material used for electric insulators, which is prepared from the following raw materials by weight percentage:

[0056] Polyethylene 45%

[0057] Toughener 8%

[0058] Inorganic filler 25%

[0059] Brominated flame retardant 15%

[0060] Synergistic flame retardant 5%

[0061] Stabilizer 0.8%

[0062] Coupling agent 0.5%

[0063] Lubricant 0.7%

[0064] The polyethylene is high-density polyethylene (HDPE) with a melt index (230°C, 5kg) of 10g / 10min;

[0065] Described toughening agent is EPDM grafted maleic anhydride;

[0066] Described inorganic filler is modified calcium carbonate, and its particle diameter is 1250 orders;

[0067] Described brominated flame retardant is brominated triazine;

[0068] The synergistic flame retardant is antimony trioxide;

[0069] Described stabilizer is made up of 0.2% antioxidant, 0.6% light stabilizer, wherein, antioxidant is compounded by antioxidant 1010 and antioxidant 168 by the ratio of 1:2; Li...

Embodiment 3

[0074] A modified polyethylene material used for electric insulators, which is prepared from the following raw materials by weight percentage:

[0075] Polyethylene 47.1%

[0076] Toughener 6%

[0077] Inorganic filler 20%

[0078] Brominated flame retardant 25%

[0079] Stabilizer 0.9%

[0080] Lubricant 1%

[0081] The polyethylene is high-density polyethylene (HDPE) with a melt index (230°C, 5kg) of 10g / 10min;

[0082] Described toughening agent is EPDM grafted maleic anhydride;

[0083] Described inorganic filler is modified calcium carbonate, and its particle diameter is 1250 orders;

[0084] Described brominated flame retardant is brominated epoxy;

[0085] Described stabilizer is made up of 0.3% antioxidant, 0.6% light stabilizer, wherein, antioxidant is compounded by antioxidant 1010 and antioxidant 168 by the ratio of 1:2; Light stabilizer is formed by UV -531 (2-hydroxy-4-n-octyloxybenzophenone) and 770 (bis(2,2,6,6-tetramethylpiperidinyl) sebacate) in a rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com