Low-concentration lithium salt electrolyte and lithium secondary battery containing same

A lithium secondary battery and electrolyte technology, applied in secondary batteries, non-aqueous electrolyte batteries, secondary battery repair/maintenance, etc., can solve problems such as cycle performance degradation, reduce reduction and decomposition, and inhibit lithium dendrites The effect of forming and reducing the amount of lithium salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Preparation of composite low-concentration lithium salt electrolyte:

[0030] The electrolyte solution is prepared in a glove box with water and oxygen content less than 0.1ppm, and the temperature is room temperature. Mix ethylene carbonate (EC) and diethyl carbonate (DEC) in a mass ratio of 3:7, seal it and put it in the refrigerator until it is cooled to -10°C, transfer it to a glove box, add LiFOP (lithium salt ( Ⅰ)) and LiAsF 6 (lithium salt (II)) to make the concentration of LiFOP 0.1mol / L, and make LiAsF 6 The concentration of the mixture is 0.4mol / L, and it is left to stand for 24 hours after being fully mixed.

[0031] 2) Preparation of electrode sheets:

[0032] Positive electrode: the positive active material LiFePO 4 , binder PVDF, and conductive agent SP are mixed according to the mass ratio of 8:1:1, N-methylpyrrolidone is added, stirred in a high-speed vibrating ball mill until stable and uniform, and the positive electrode slurry is obtained; the ...

Embodiment 2~8 and comparative example 1~4

[0042] The composition of the electrolyte and the electrodes used are shown in Table 1. The specifications of the lithium metal negative electrode used are 15.6 mm in diameter and 0.45 mm in thickness, and the EMC and DMC are ethyl methyl carbonate and dimethyl carbonate, respectively. Test method is the same as embodiment 1.

[0043] Table 1: Electrolyte composition and electrode selection of Examples 1-8 and Comparative Examples 1-4. Wherein EMC and DMC are ethyl methyl carbonate and dimethyl carbonate respectively.

[0044]

[0045] The electrolytes of Examples 1-3 and Comparative Examples 1-2 were tested for liquid absorption rate and contact angle, and the test results are shown in Table 2.

[0046] The above batteries were tested for cycle performance at room temperature (25°C), and the test results are shown in Table 3.

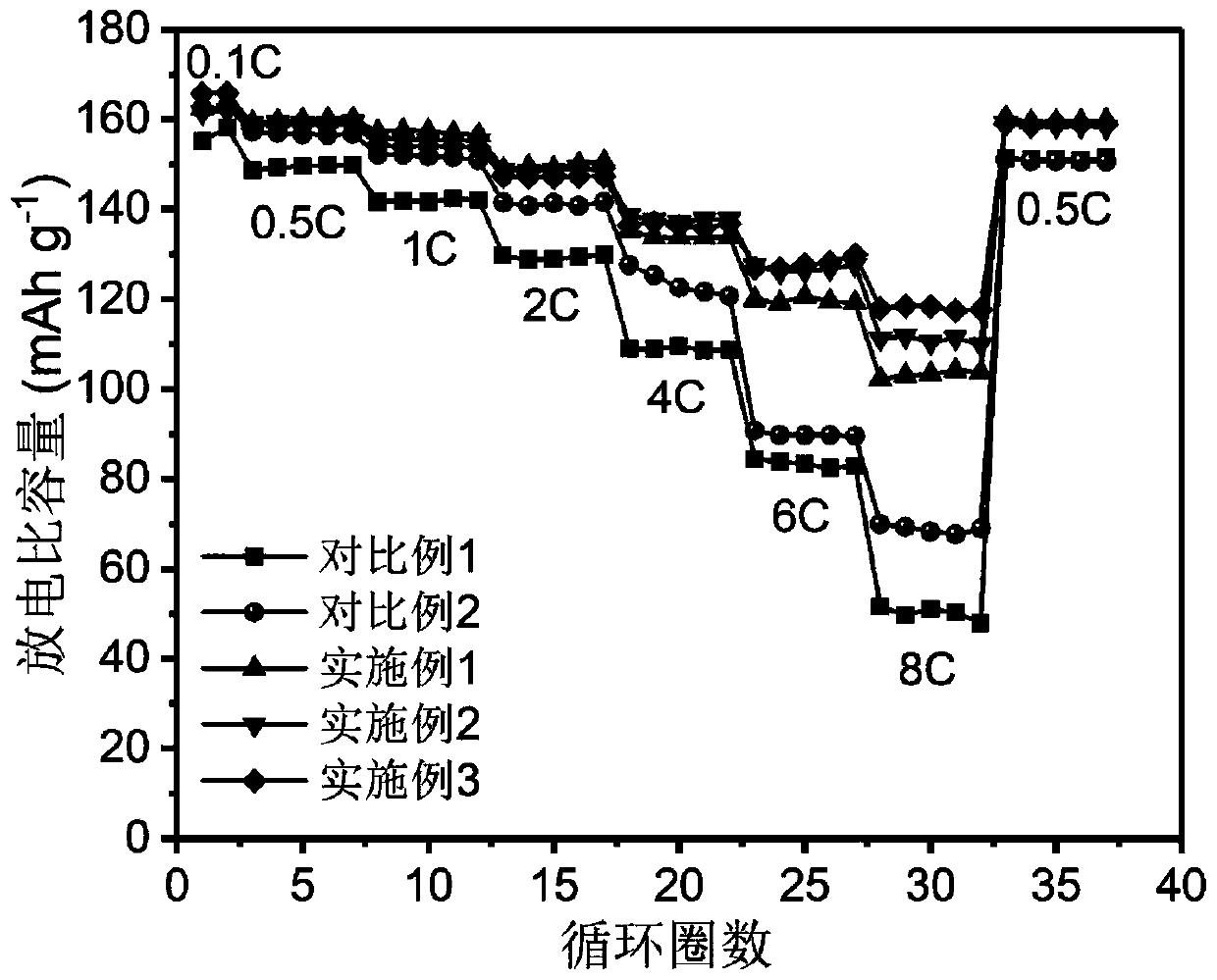

[0047] Carry out rate performance test to embodiment 1~3 and comparative example 1~2, test result sees figure 1 .

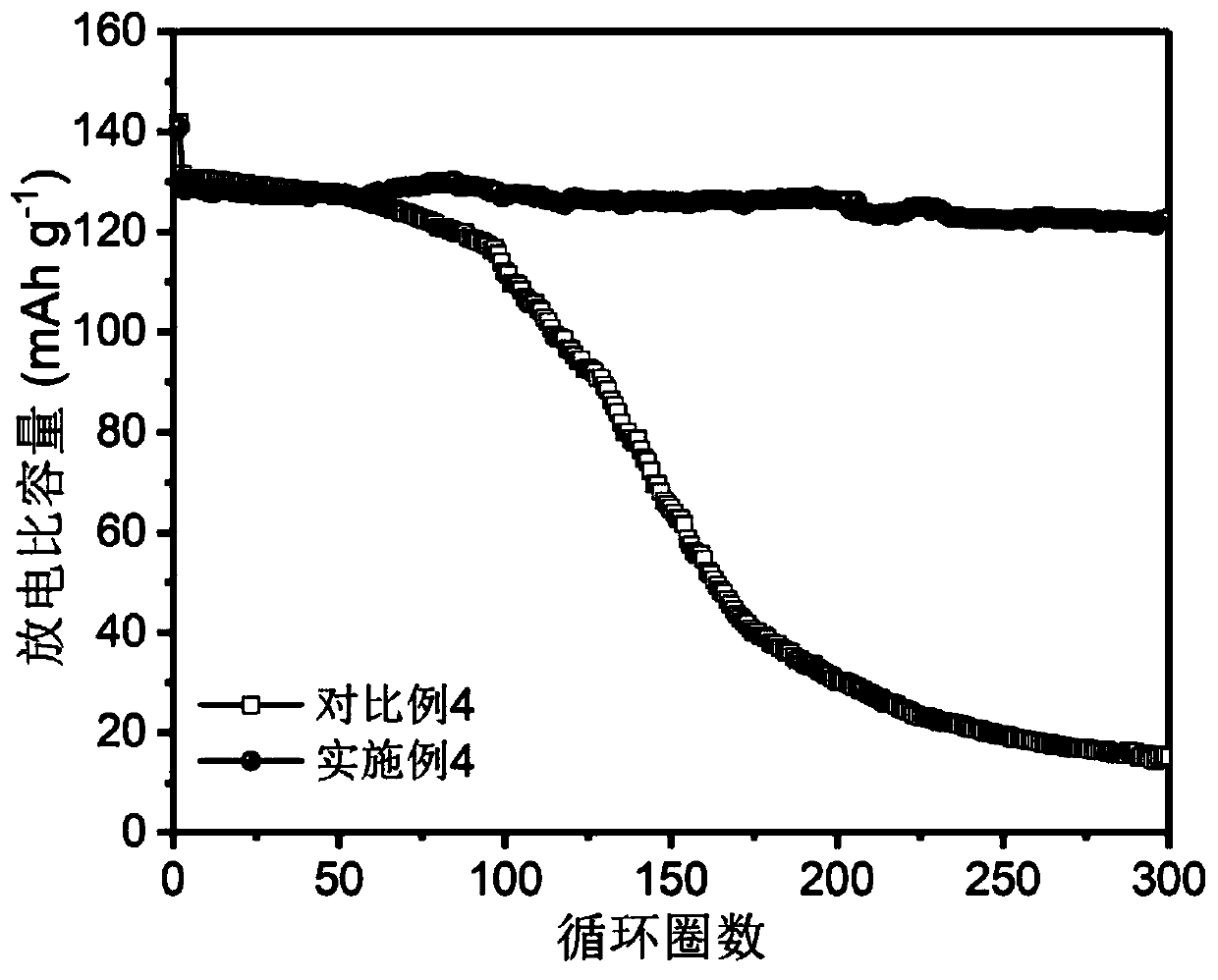

[0048] Carry out the 1C cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com