DISA vertical green molding sand molding line air cylinder mold and casting process thereof

A casting process and green sand technology, which is applied to the B096 cylinder mold of the DISA vertical green sand molding line and its casting process field, can solve the problems of sticking sand, casting shrinkage holes, weight-reducing holes and succulents, etc. The effect of flow velocity and enhanced slag avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The casting process of a DISA vertical green sand molding line B096 cylinder is as follows: including molding process, smelting process, inoculation process, pouring process, sand falling process, mechanical performance testing, primary shot blasting, external grinding, secondary shot blasting, inspection wrap up and store;

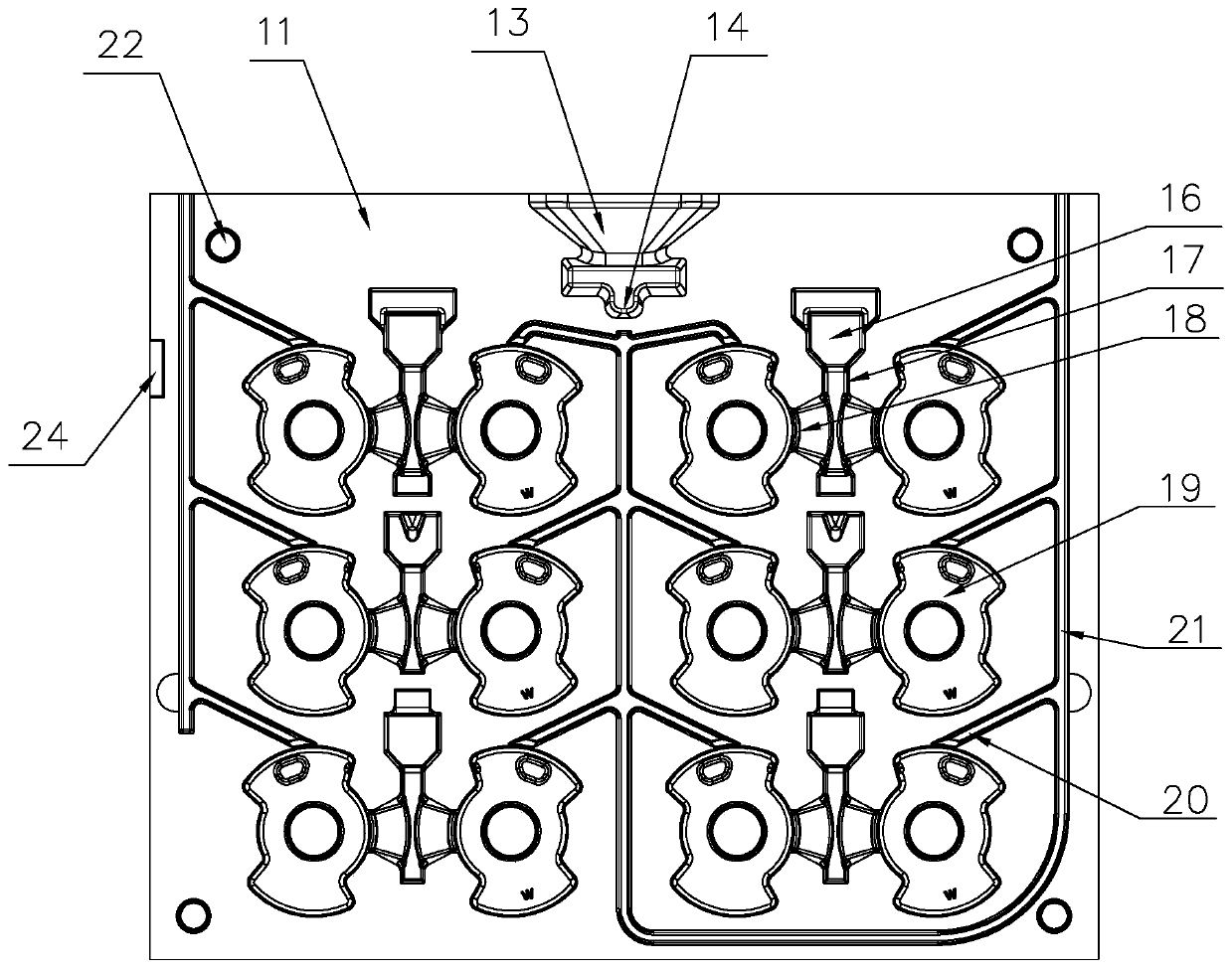

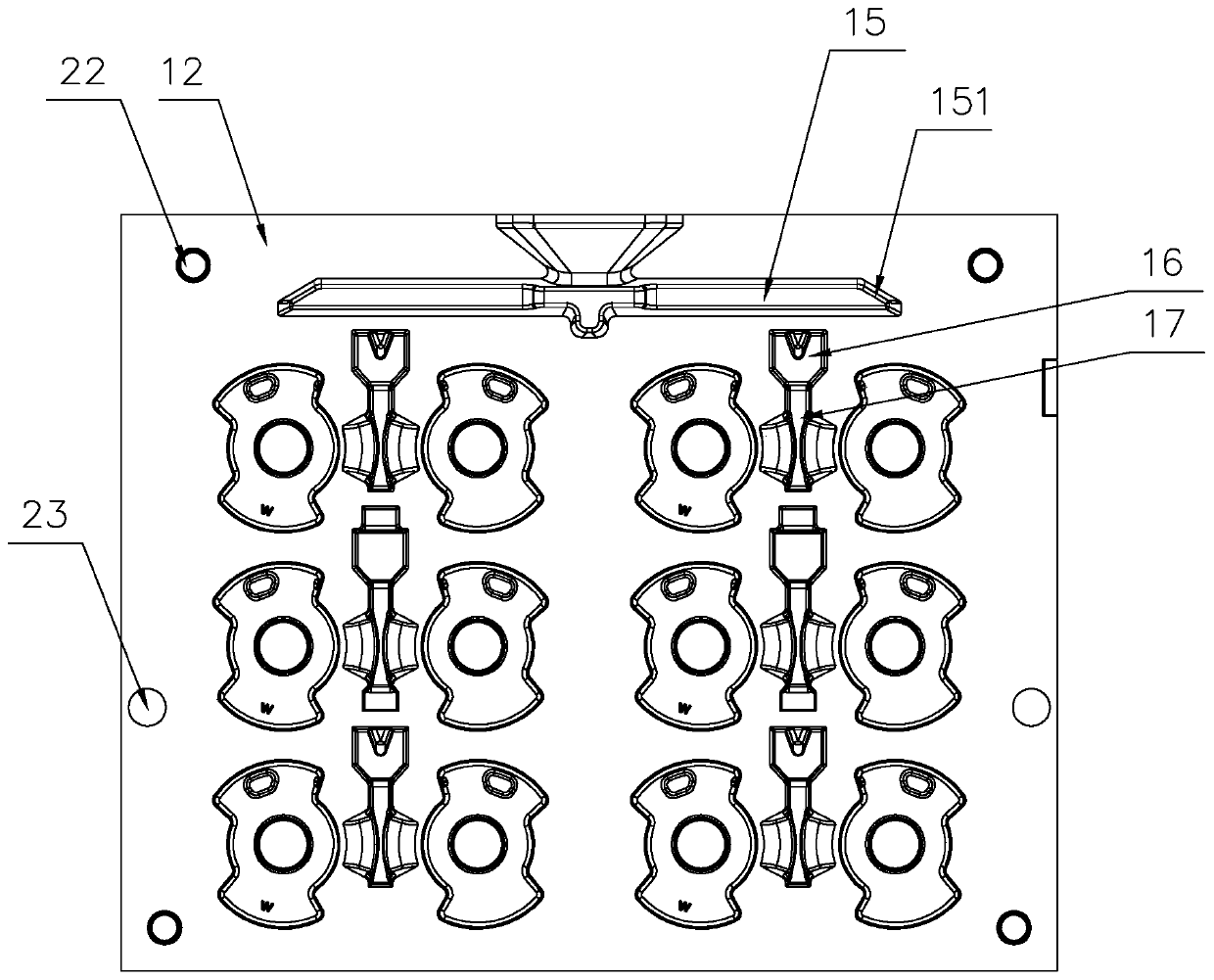

[0044] 1) molding process, the molding process adopts the green molding sand vertical line boxless molding, and the green molding sand vertical line boxless molding adopts the molding template as the overall template;

[0045] Modeling requirements: sand shooting pressure 0.22MPa, extrusion pressure 0.9MPa, select operation 3A;

[0046] Molding sand performance requirements: sand thickness 210mm, sand hardness 85 based on B-type hardness, moisture content 3.3%, compaction rate 35%, wet compressive strength 0.18Mpa, air permeability 90%, volatile matter 1.5%, shear strength 0.03Mpa, The moisture content of the old sand returned to the sand is 1.5%, t...

Embodiment 2

[0059] The casting process of a DISA vertical green sand molding line B096 cylinder is as follows: including molding process, smelting process, inoculation process, pouring process, sand falling process, mechanical performance testing, primary shot blasting, external grinding, secondary shot blasting, inspection wrap up and store;

[0060] 1) molding process, the molding process adopts the green molding sand vertical line boxless molding, and the green molding sand vertical line boxless molding adopts the molding template as the overall template;

[0061] Modeling requirements: sand shooting pressure 0.24MPa, extrusion pressure 0.85MPa, select operation 3A;

[0062] Molding sand performance requirements: sand thickness 210mm, sand hardness 85 based on B-type hardness, moisture content 3.4%, compaction rate 35%, wet compressive strength 0.18Mpa, air permeability 100%, volatile matter 2.0%, shear strength 0.03Mpa, The moisture content of the old sand returned to the sand is 1.8...

Embodiment 3

[0075] The casting process of a DISA vertical green sand molding line B096 cylinder is as follows: including molding process, smelting process, inoculation process, pouring process, sand falling process, mechanical performance testing, primary shot blasting, external grinding, secondary shot blasting, inspection wrap up and store;

[0076] 1) molding process, the molding process adopts the green molding sand vertical line boxless molding, and the green molding sand vertical line boxless molding adopts the molding template as the overall template;

[0077] Modeling requirements: sand shooting pressure 0.25MPa, extrusion pressure 1MPa, selection operation 3A;

[0078] Molding sand performance requirements: sand thickness 215mm, sand hardness 90 based on B-type hardness, moisture content 3.2%, compaction rate 38%, wet compressive strength 0.22Mpa, air permeability 120%, volatile matter 1.5%, shear strength 0.04Mpa, The moisture content of the old sand returned to the sand is 2.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wet compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com