Double-layer composite wave-absorbing material and its preparation method

A double-layer composite and wave-absorbing material technology, applied in the field of materials, can solve the problems of thinness, lightness, width, and strength that are not completely satisfactory, and achieve good electromagnetic shielding effects, good mechanical properties, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

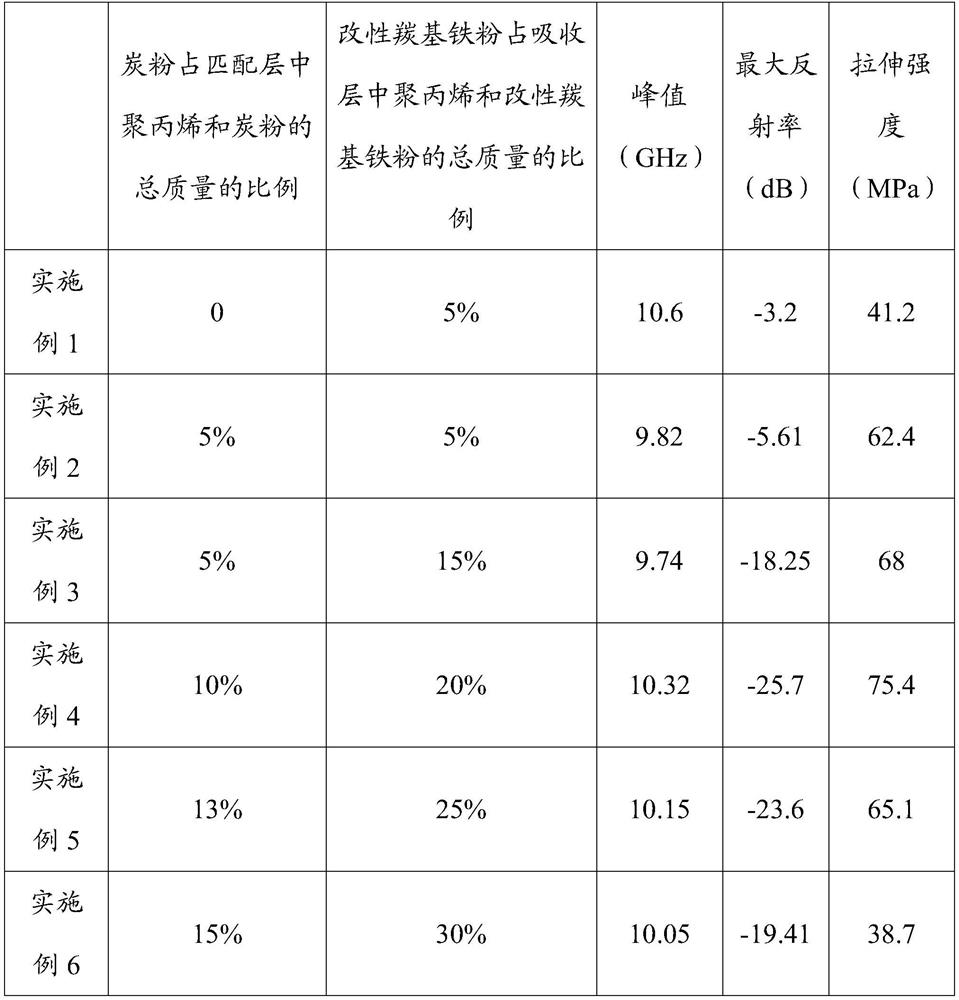

[0018] The preparation method of the double-layer composite wave-absorbing material is briefly described below. Weigh the carbon powder, heat the carbon powder at 550°C-650°C for 50-70 minutes to remove the organic matter on the surface, dry the polypropylene pellets at 90-110°C for 50-70 minutes to reduce the moisture content of the raw materials, and dry the polypropylene pellets at 90-110°C for 50-70 minutes Add carbon powder with a mass of 5% to 13% of the total mass of polypropylene and carbon powder in the material, fully mix the mixed raw materials in the extruder, and control the temperature of the feeding area, melting area and head of the extruder , extrusion granulation, and repeated mixing and extrusion granulation according to this operation step until the two raw materials are mixed evenly. Wherein, the carbon powder of the present invention has the advantages of high acid and wear resistance, low density and good electrical conductivity, but the wave-absorbing e...

Embodiment 1

[0023] No material is added to the polypropylene pellets, and the raw materials are extruded and pelletized in a twin-screw extruder, wherein the temperature range of the extruder is 170-220°C.

[0024] Weigh the carbonyl iron powder, mix the carbonyl iron powder with the silane coupling agent KH550 solution (the amount of the silane coupling agent KH550 is 6% of the mass of the carbonyl iron powder), and then ultrasonically disperse the mixed solution in a water bath at 40°C to make The iron powder is uniformly dispersed in the solution, reacted for about 40 minutes, the reactant is filtered, washed with deionized water for several times, and dried to obtain organosilane-modified surface-aminated carbonyl iron particles. Weigh the processed carbonyl iron powder, add carbonyl iron powder to the polypropylene pellets, the quality of the carbonyl iron powder is 5% of the total mass of polypropylene and carbonyl iron powder, fully mix the raw materials in the extruder Mixing, whe...

Embodiment 2

[0027] Weigh the carbon powder, heat at 600°C for 60 minutes, dry the polypropylene pellets at 100°C for 60 minutes to reduce the water content of the raw material, add carbon powder to the polypropylene pellets, the quality of the carbon powder is equal to that of polypropylene and carbon powder 5% of the total mass, the mixed raw materials are fully mixed in the extruder, wherein the extruder feed zone, melting zone and head temperature are 180 ° C, 185 ° C, 190 ° C, extrusion granulation, and according to This operation step is repeated mixing, extrusion and granulation until the two raw materials are mixed evenly.

[0028] Weigh the carbonyl iron powder, mix the carbonyl iron powder with the silane coupling agent KH550 solution (the amount of the silane coupling agent KH550 is 6% of the mass of the carbonyl iron powder), and then ultrasonically disperse the mixed solution in a water bath at 40°C to make The iron powder is uniformly dispersed in the solution, reacted for ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com