Bending-resistant carbon nanotube/graphene composite film, its preparation method and application

A graphene composite and carbon nanotube technology, applied in the direction of graphene, nano-carbon, carbon compounds, etc., to achieve high bending resistance, mature operation technology, and good electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

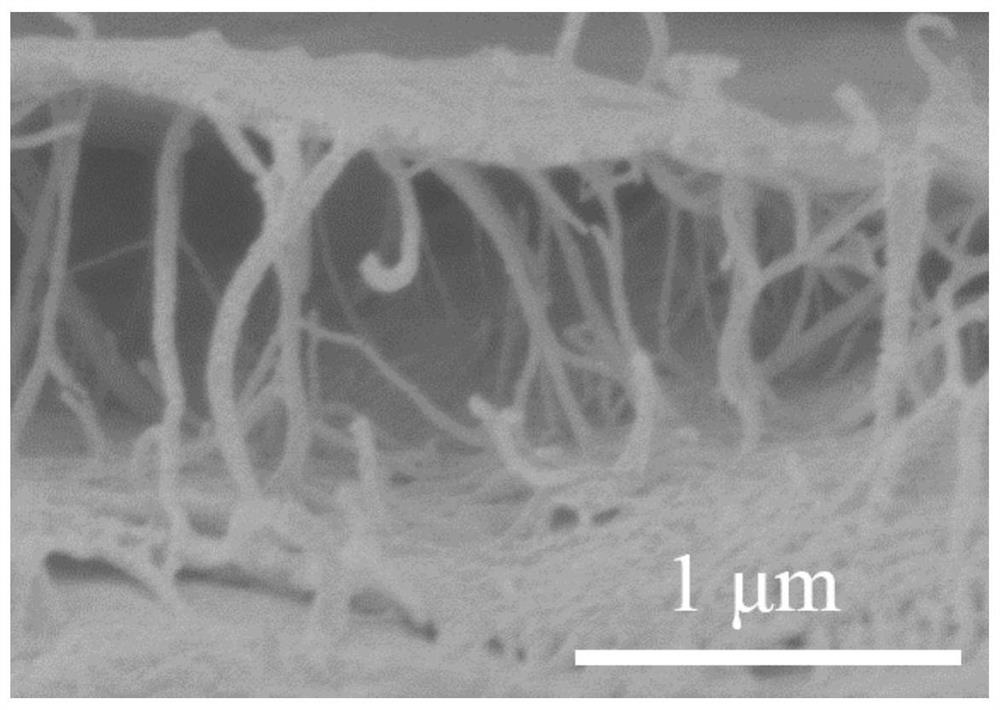

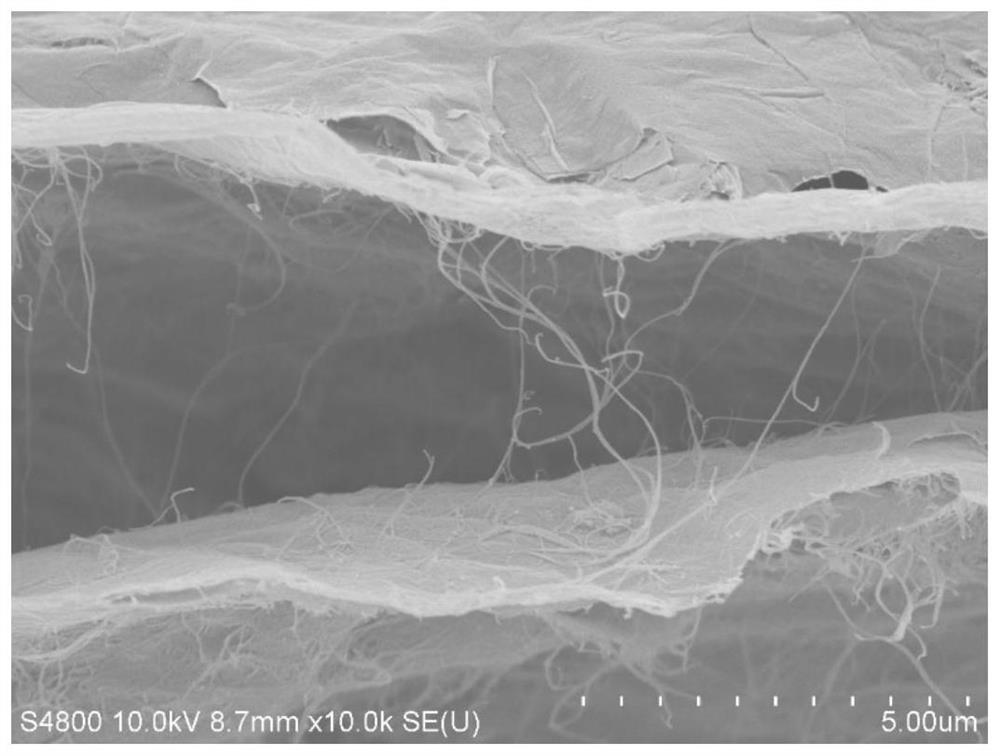

[0029] The preparation principle of the present invention is that: the present invention carries out low-temperature carbonization treatment on carbon nanotube / graphene oxide composite film and high-temperature graphitization treatment in high-temperature graphitization furnace, and graphene oxide will be further reduced to reduction oxidation during the heating process. Graphene, in this process, graphene sheets continuously expand to form a porous structure, and due to the existence of carbon nanotubes, there will be carbon nanotubes between the two sheets to support and fix them, forming a porous network structure . The simultaneous improvement of the two processes of low-temperature carbonization and high-temperature graphitization endows the carbon nanotube / graphene composite film with excellent properties. After the graphitization treatment at 2200 ° C and above, the carbon nanotube / graphene composite film has The foldable property is mainly due to the support and fixati...

Embodiment 1

[0075] In step 1, the Hummer method was used to synthesize GO, and the GO solution was diluted to 0.3 mg / mL for later use, and its solvent was an aqueous solution. SDBS was used to disperse SWCNTs, and an aqueous solution was also used to prepare 1 mg / mL. First, it was treated with an ultrasonic cleaner for 1 hour, and then treated with an ultrasonic cell pulverizer for 2 hours to obtain a SWCNT dispersion.

[0076] Step 2: Prepare SWCNT / GO mixed solutions with SWCNT and GO mass ratios of 0, 2%, 4%, 6%, 8%, and 10% respectively, and prepare SWCNT / GO composite films by vacuum filtration.

[0077] Step 3: Carbonize the SWCNT / GO composite film in a tubular CVD furnace. The gas environment used is argon, and the temperature is raised from room temperature to 1000 °C at a heating rate of 5 °C / min, then kept for half an hour, and then cooled naturally to room temperature.

[0078] Step 4, put the carbonized sample in a high-temperature graphitization furnace, and perform high-tempe...

Embodiment 2

[0081] In step 1, the Hummer method was used to synthesize GO, and the GO solution was diluted to 0.3 mg / mL for later use, and its solvent was an aqueous solution. SDBS was used to disperse SWCNTs, and an aqueous solution was also used to prepare 1 mg / mL. First, it was treated with an ultrasonic cleaner for 1 hour, and then treated with an ultrasonic cell pulverizer for 2 hours to obtain a SWCNT dispersion.

[0082] Step 2: Prepare SWCNT / GO mixed solutions with SWCNT and GO mass ratios of 0, 2%, 4%, 6%, 8%, and 10% respectively, and prepare SWCNT / GO composite films by vacuum filtration.

[0083] Step 3: Carbonize the SWCNT / GO composite film in a tubular CVD furnace. The gas environment used is argon, and the temperature is raised from room temperature to 400 °C at a heating rate of 5 °C / min, and then kept for half an hour, and then cooled naturally to room temperature.

[0084] Step 4, put the sample after the carbonization treatment in a high-temperature graphitization furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com