A hydrothermal carbonization treatment equipment for livestock and poultry manure

A technology of hydrothermal carbonization and livestock and poultry manure, which is applied in the fields of animal husbandry wastewater treatment, pyrolysis treatment sludge, dehydration/drying/thickened sludge treatment, etc. It can solve the problem of carbonization furnace bursting, internal pressure increase, and difficulty in reaching scale problems such as chemical processing, to achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

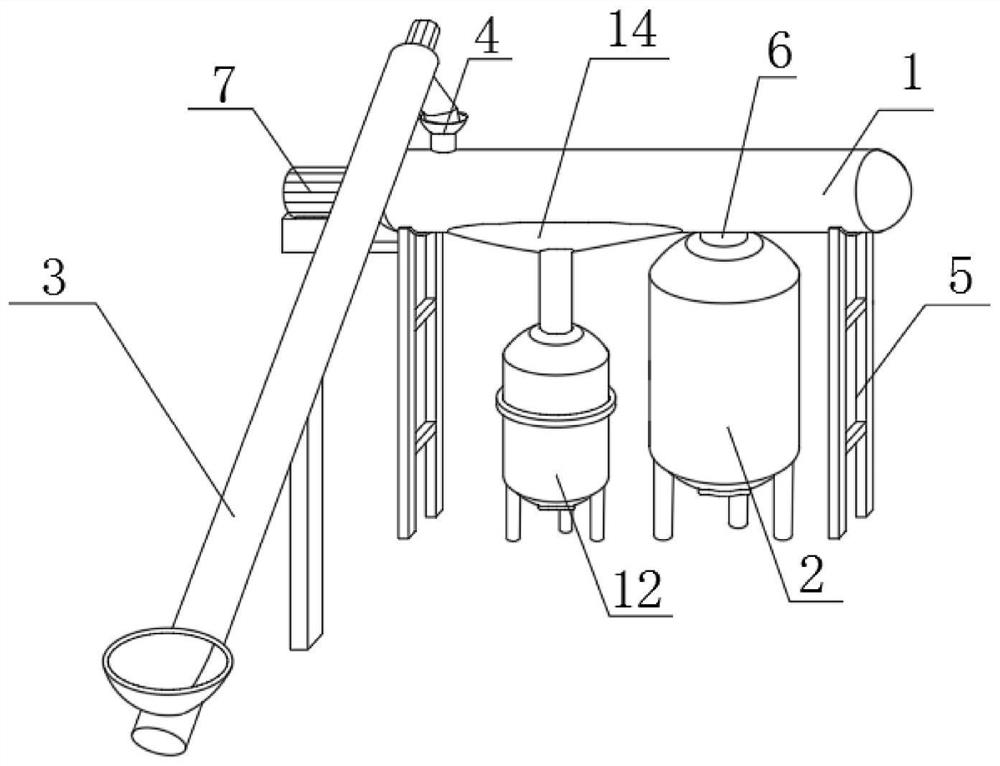

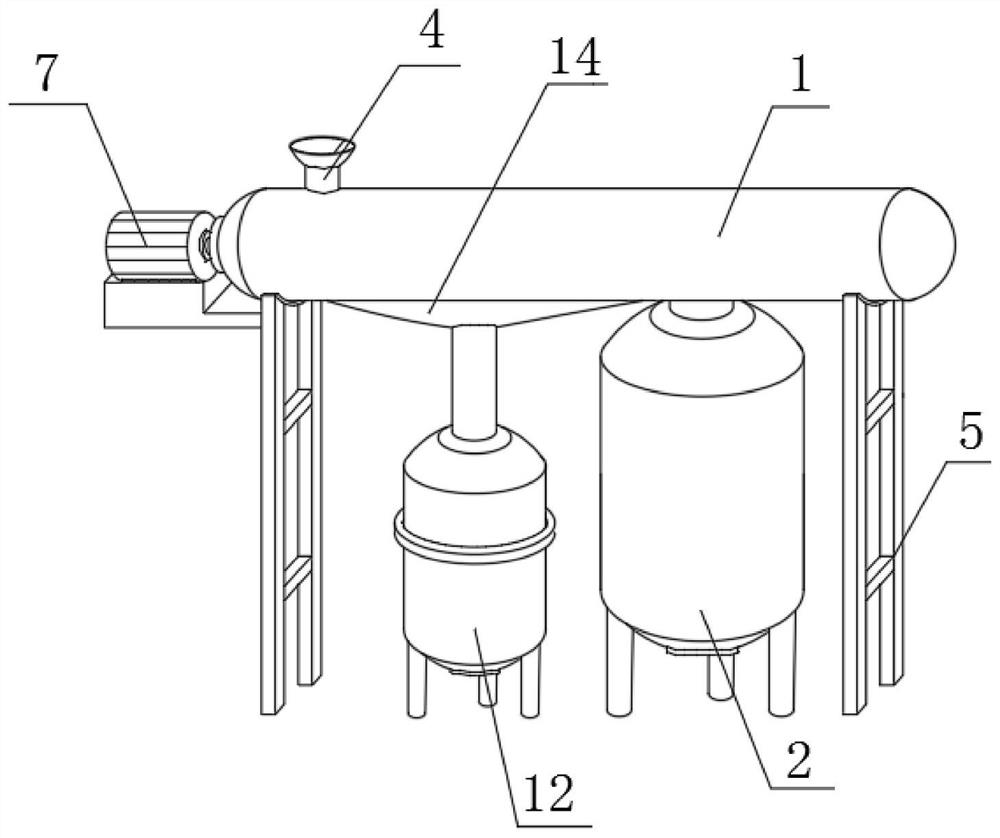

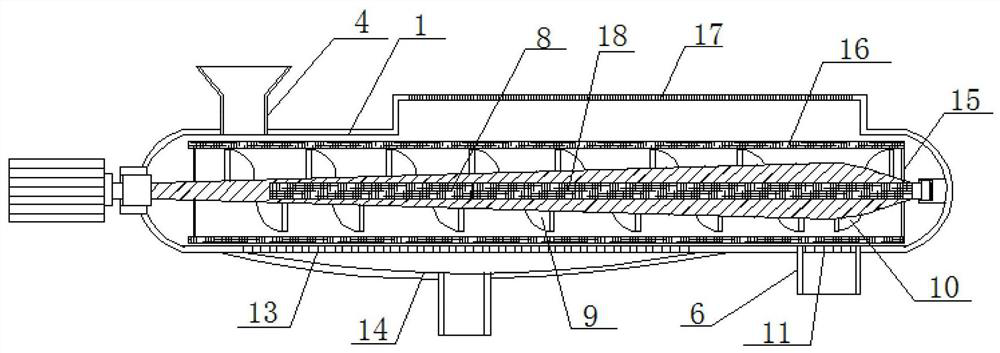

[0027] See Figure 1 ~ 5 In the embodiment of the present invention, a livestock and poultry feces hydrocarbon treatment apparatus includes a stirring drying tank 1, a hydrothermal carbonizing furnace 2, and a screw conveyor 3, wherein the feed end of the stirring drying box 1 is The screw conveyor 3 is connected, and the discharge end of the stirring drying tank 1 is connected to the hydrothermal carbonization furnace 2, and the stirring drying tank 1 is provided with a transport stirred blade 9 and a heating assembly, the transport stirred blade. The 9 interval is arranged in the axial direction of the agitating shaft 8, which is characterized in that

[0028] The angle between the extension direction of the conveying agitating blade 9 and the axis of the stirring shaft 8 is a variable adjustable arrangement, and the higher the temperature in the stirring drying box, the direction of the transport stirred blade 9 and The smaller the angle between the axes of the agitating shaft 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com