Efficient, energy-saving and environment-friendly gas/oil steam boiler

A high-efficiency, energy-saving and environmentally friendly technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of low boiler safety, insufficient fuel combustion, high difficulty in waste heat recovery, and avoid the risk of bursting. , the effect of increasing the thermal contact area and improving the energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

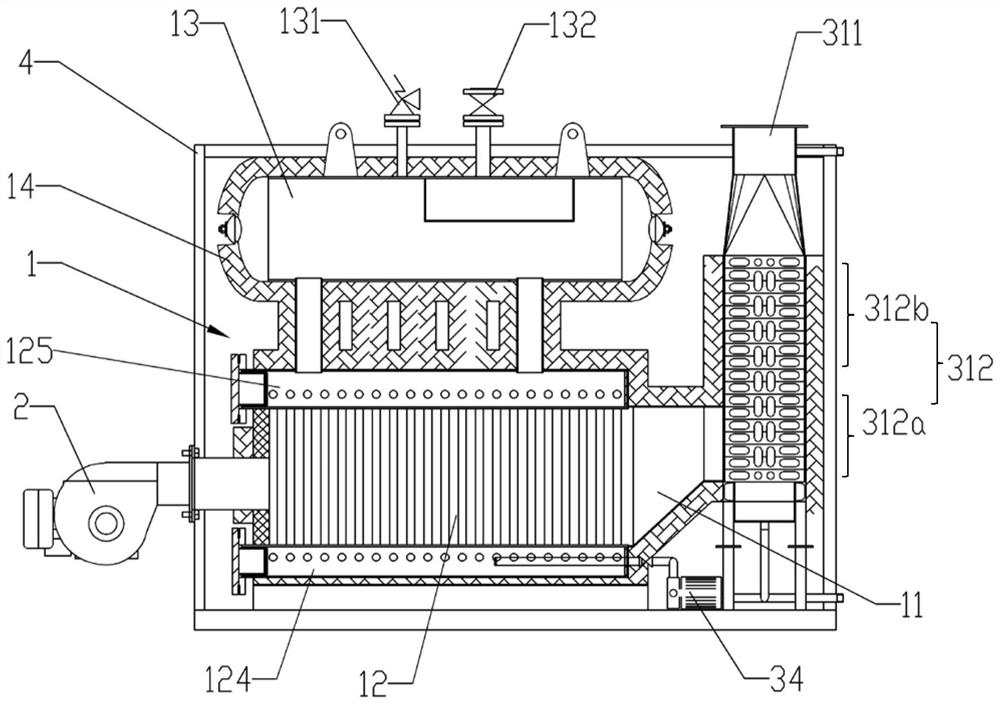

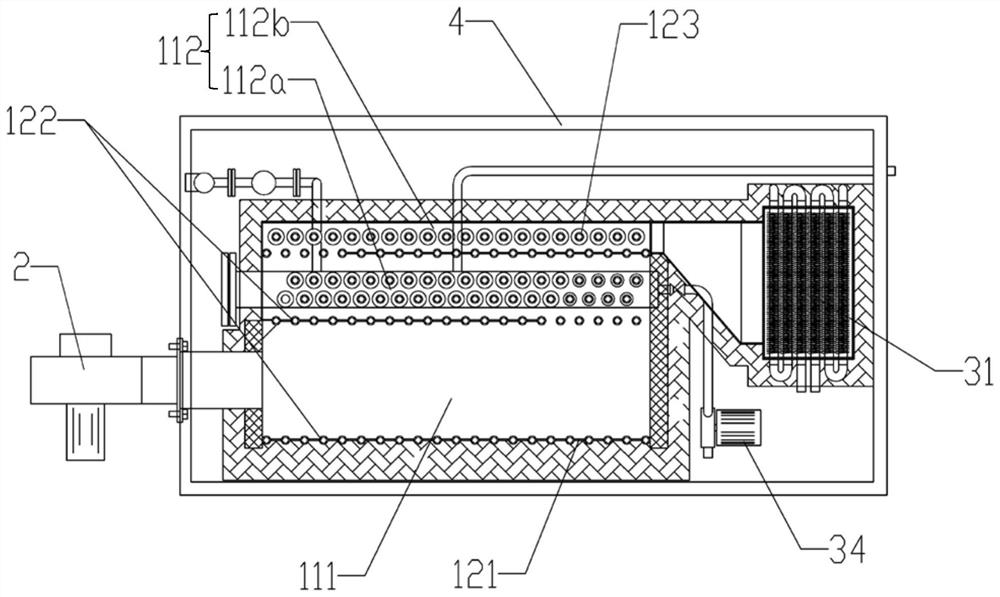

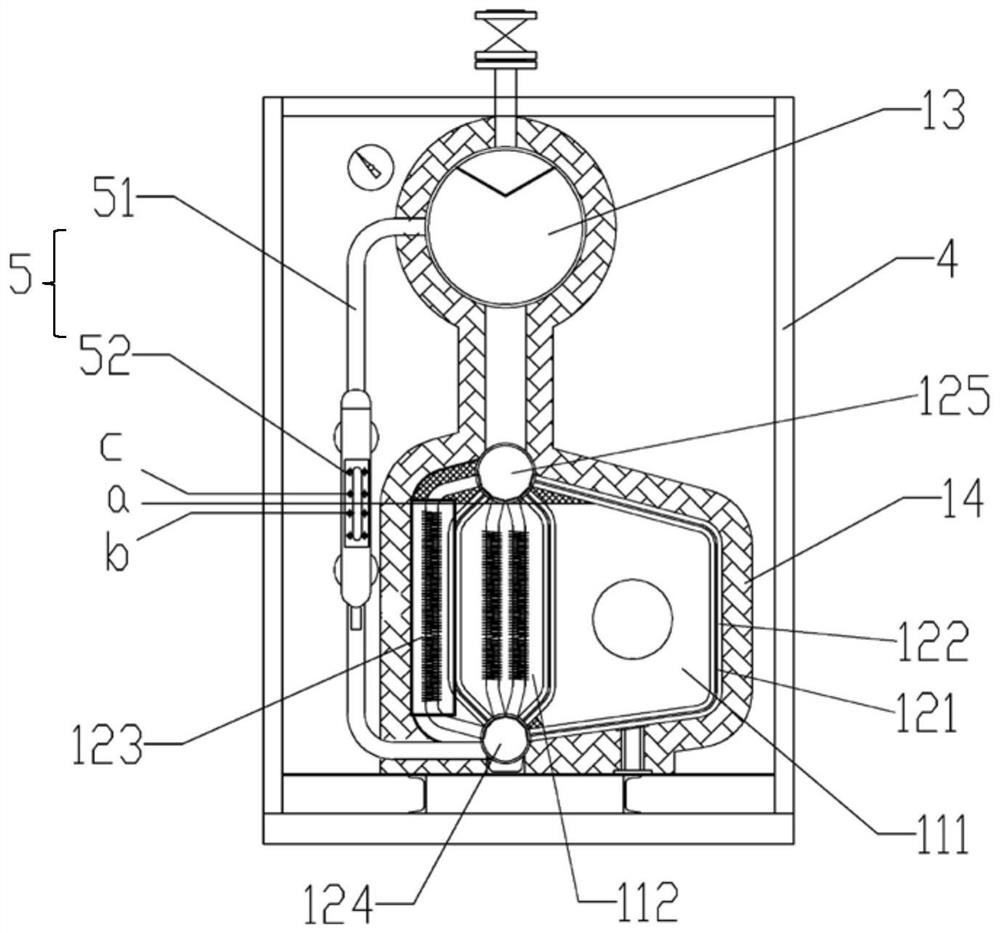

[0045] Figure 1-Figure 4 A high-efficiency, energy-saving and environment-friendly gas / oil steam boiler according to a preferred embodiment of the present invention is shown, which includes a boiler body 1 , a burner 2 , a waste heat utilization system 3 and a steel frame outsourcing 4 .

[0046] The boiler body 1 includes a furnace 11, a heat exchange unit 12, a steam drum 13 and a furnace wall 14; the heat exchange unit 12 includes a water-cooled wall 121, a first heat-exchange tube 122 and a second heat-exchange tube 123, and the water-cooled wall 121 is longitudinally arranged to place the furnace 11 is divided into a combustion zone 111 and a convection zone 112, and the combustion zone 111 and the convection zone 112 form a loop channel; the first heat exchange tube 122 is vertically arranged along the interface on both sides of the combustion zone 111 and the interface of the convection zone 112, and is water-cooled The wall 121 is integrated with the first heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com