Polarization-maintaining base material with simple section structure and efficient preparation method of polarization-maintaining base material

A profile, simple technology, applied in the field of simple profile structure polarization maintaining base material and its high-efficiency preparation, can solve the problems such as difficult to make breakthrough improvement, achieve the effect of reducing equipment stability requirements, high internal stress, and price reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

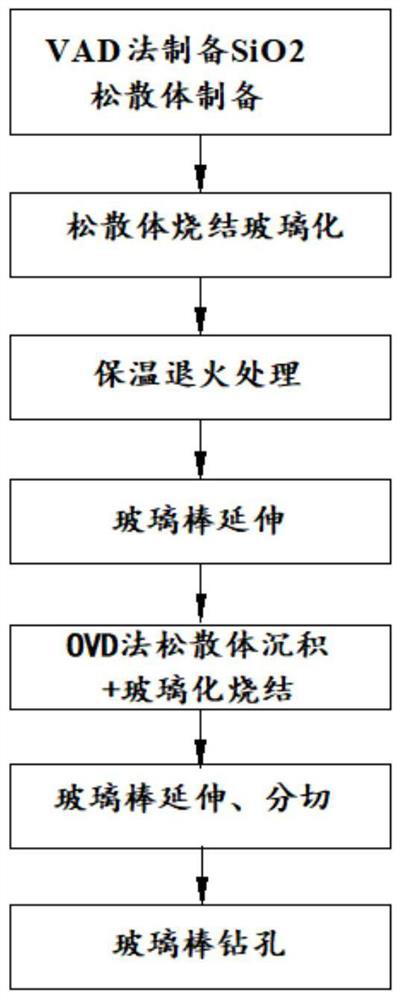

[0030] The high-efficiency preparation method of the simple cross-section structure polarization-maintaining base material of the present invention comprises the following steps:

[0031] A germanium-doped VAD core layer 1 and a fluorine-doped VAD outer cladding layer 2 are prepared by VAD technology. Deposition of SiO by VAD process 2 In the case of loose body, the core layer is doped with germanium, and then fluorine is doped in the outer cladding 2 of the VAD through sintering and fluorine doping process, and then heat preservation treatment in a dynamic holding furnace. The holding temperature is 1100±30°C, and the holding time is not less than 20h. The moving speed is 2-10mm / min, the rotating speed is 1-3 revolutions / min, and after the end, it is cooled to 800±25°C with the furnace; then, it is stretched in equal proportions to obtain a transparent and defect-free glass rod, where the extended diameter is recorded as D1, D1 is 33±0.5mm, the curvature of the rod body is ≤...

Embodiment 1

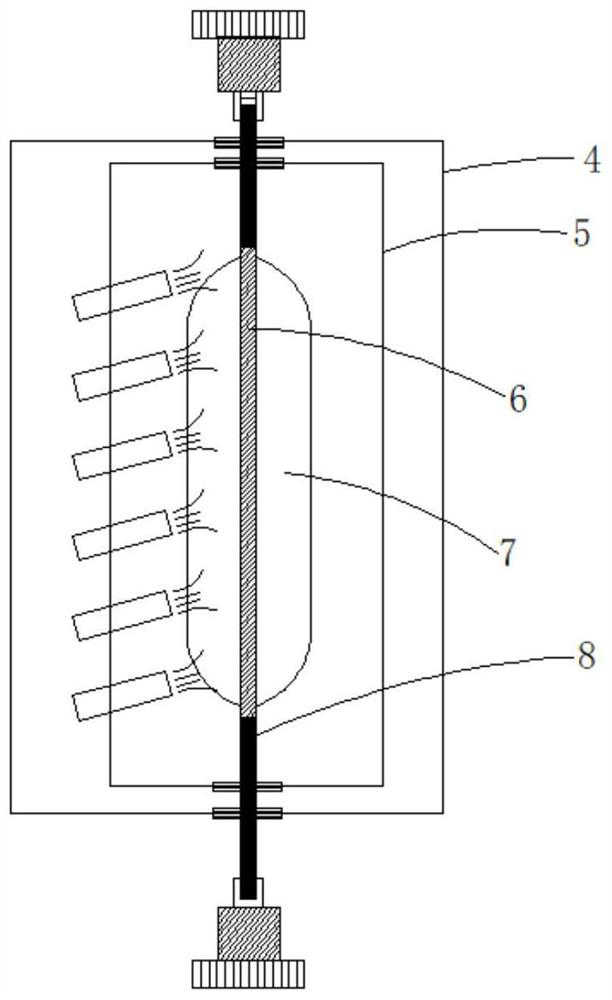

[0034] Such as Figure 1-4 As shown, the simple cross-sectional structure of the polarization-maintaining base material includes VAD core layer 1, VAD outer cladding layer 2 and OVD cladding layer 7 from the inside to the outside, wherein the VAD core layer 1 is doped with GeO 2 , VAD outer cladding 2 is made of pure Si, VAD outer cladding 2 is doped with fluorine, OVD cladding 7 is made of SiO 2 .

[0035] The high-efficiency preparation method of the polarization-maintaining base material with a simple cross-section structure in this embodiment includes the following steps:

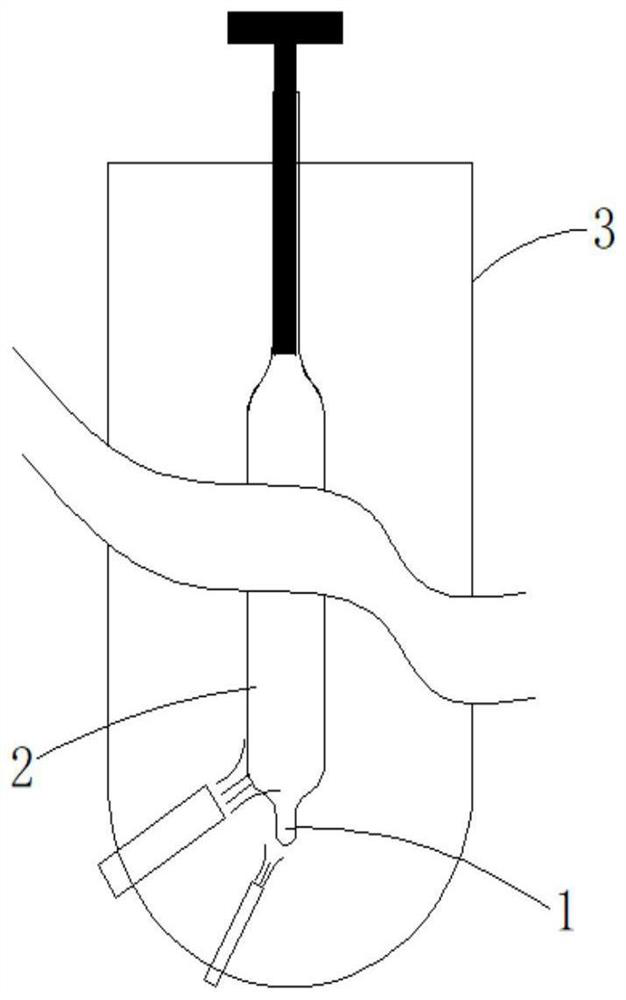

[0036] 1), using VAD equipment 3, through SiCl 4Preparation of SiO by Reaction with Hydrogen Oxygen Flame 2 Bulk body, during deposition, the VAD core layer 1 is doped with GeO 2 , and its relative refractive index n1 is 0.7%; at the same time, a VAD outer cladding layer 2 is deposited outside the VAD core layer 1;

[0037] 2) Place the semi-finished product obtained in step 1) in a sintering devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com