High-stability polyurethane curing agent and preparation process thereof

A polyurethane curing agent, high stability technology, applied in the field of polyurethane curing agent, can solve the problems of quality reduction, achieve the effect of improving performance quality, good dispersibility, and prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

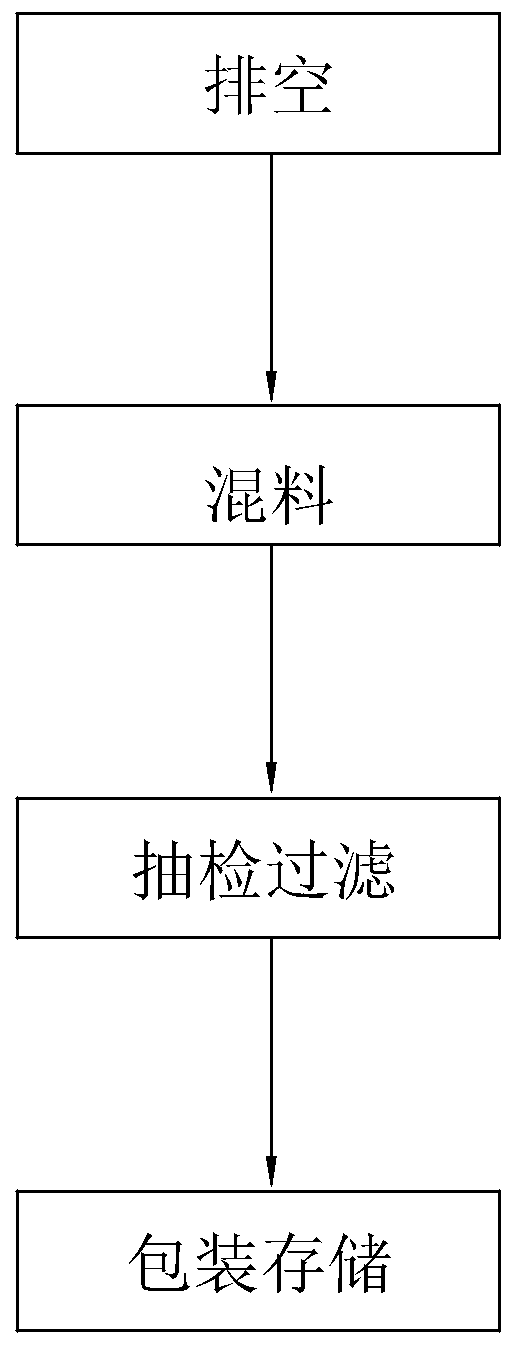

[0047] Example 1: A high-stability polyurethane curing agent, the components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0048] Step 1, empty, fill the closed stirred tank with nitrogen, and measure the oxygen content at the bottom of the stirred tank with an oxygen meter, and the measured oxygen content is 0.87%;

[0049] Step two, mix the materials, mix the corresponding parts by weight of DESMODURN 3390, ethyl acetate, ethyl oleate, sodium lauryl sulfate, ethyl orthoformate, 1,3-oxazepine, dialkyl Diphenylamine and citric acid are transported to the stirred tank by a magnetic pump, and protected by nitrogen during transport, and then stirred and mixed uniformly at a stirring speed of 1200 rpm and a time of 25 minutes to obtain sample materials;

[0050] Step three, sampling and filtering, testing the obtained sample materials, and removing impurities from the tested sample materials through the filter element filter...

Embodiment 2-8

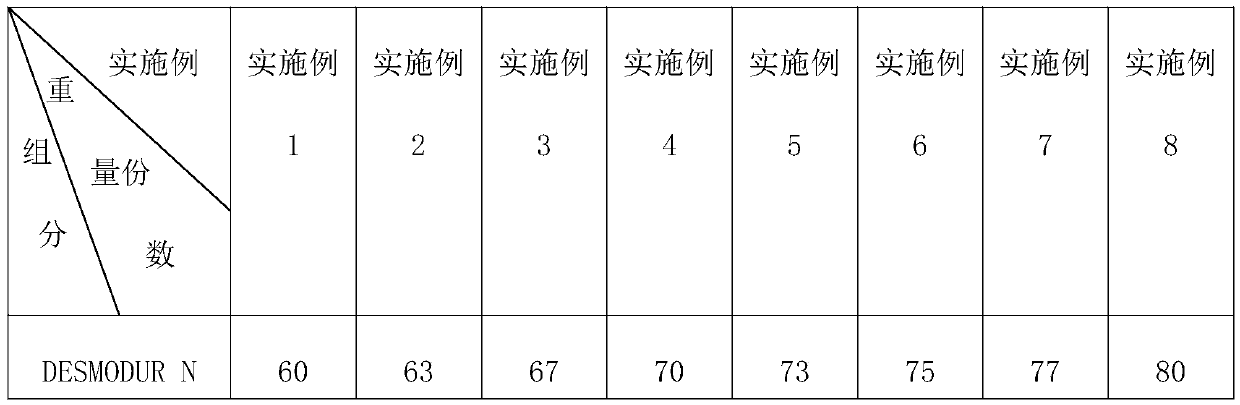

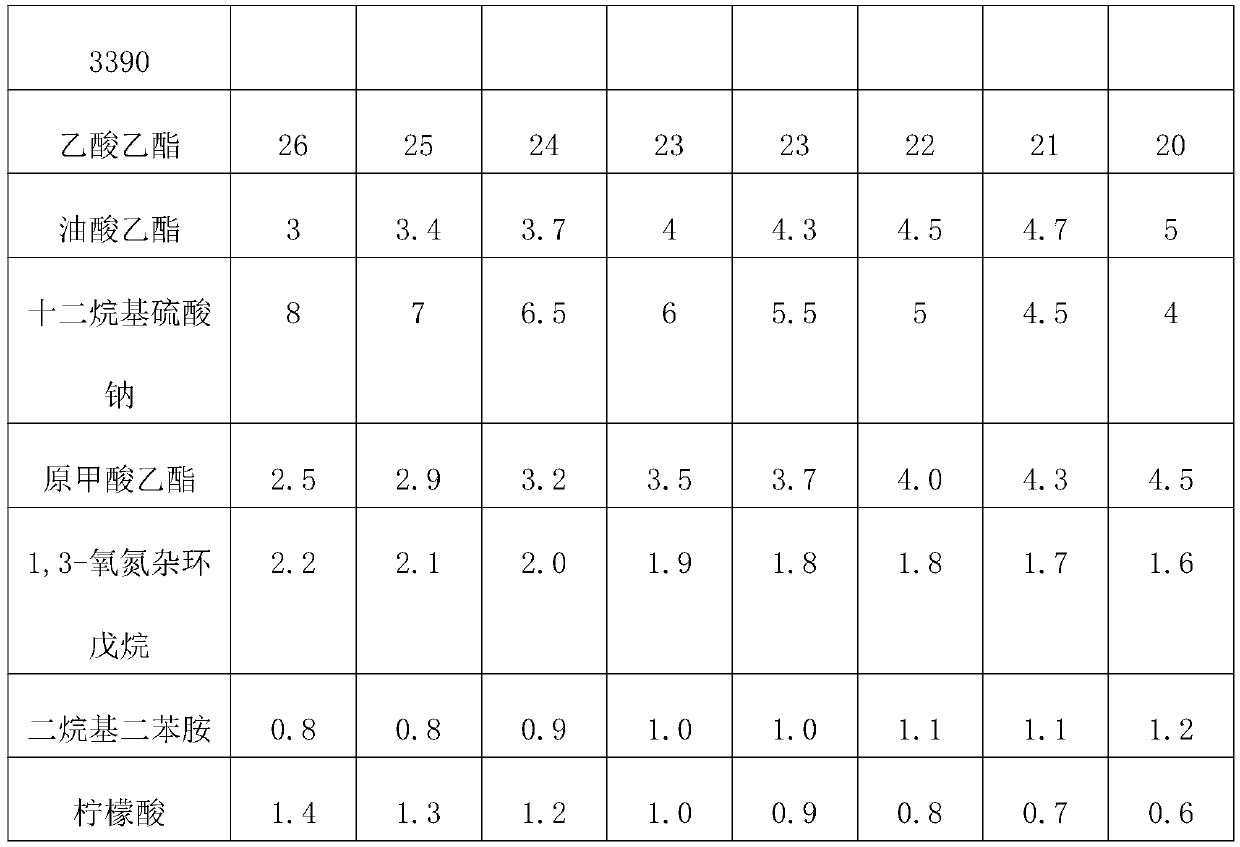

[0052] Example 2-8: A high-stability polyurethane curing agent. The difference from Example 1 is that the components and their corresponding weight parts are shown in Table 1.

[0053] Table 1 Components and parts by weight in Examples 1-8

[0054]

[0055]

Embodiment 9

[0056] Example 9: A high-stability polyurethane curing agent. The difference from Example 1 is that step 2 is specifically set to mix materials, and the corresponding weight parts are 60 parts of DESMODUR N 3390 and 26 parts of ethyl acetate. Ester, 3 parts of ethyl oleate, 8 parts of sodium lauryl sulfate, 2.5 parts of ethyl orthoformate, 2.2 parts of 1,3-oxazolane, 0.8 parts of tributyl phosphite And 1.4 parts of citric acid are transported to the stirring tank through a magnetic pump, and protected with nitrogen during transport, and then stirred and mixed uniformly, at a stirring speed of 1200 rpm and a time of 25 minutes, to obtain a sample material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com