Polysiloxane modified cyanate resin base shape memory material with high glass-transition temperature and preparation method thereof

A technology of cyanate ester resin and transition temperature, which has good application prospects in all fields, can solve the problem of low use temperature, and achieve the effects of improved shape memory performance, excellent mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

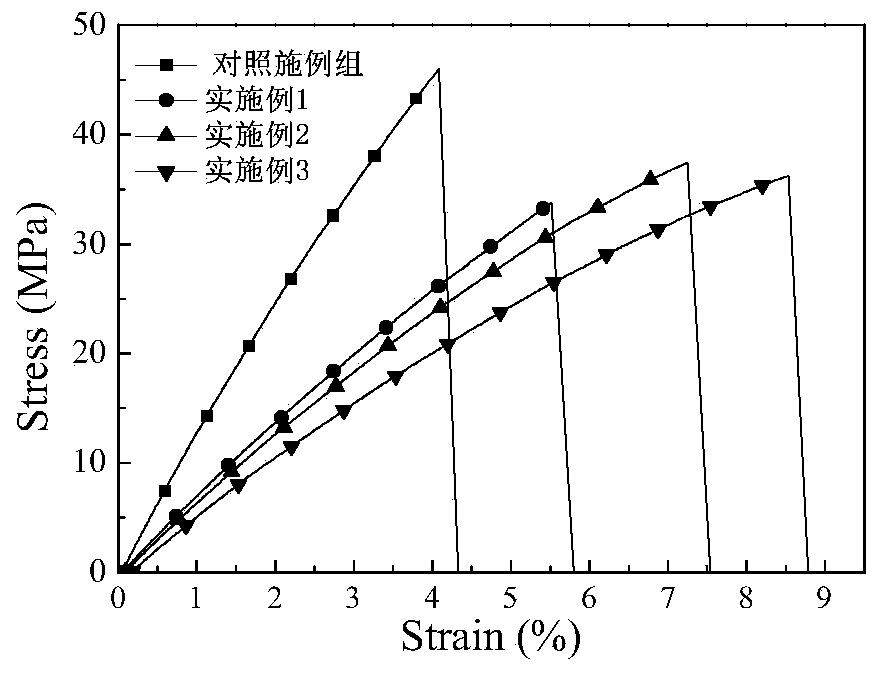

Embodiment 1

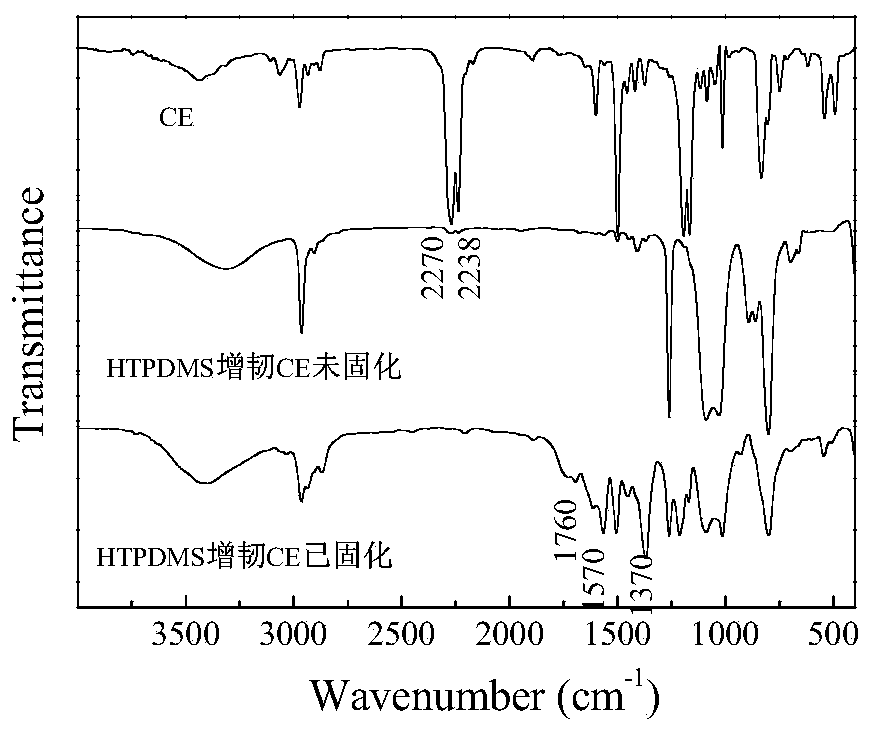

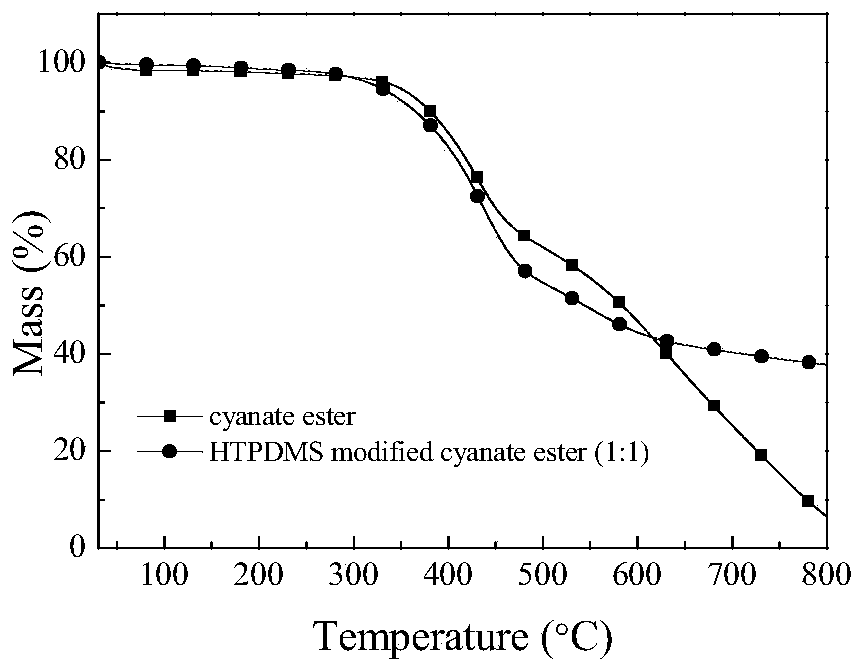

[0032] The preparation method of polysiloxane-modified cyanate resin-based shape memory material is as follows: weigh 100 g of AL-3040 epoxy resin, 120 g of hydroxyl-terminated polydimethylsiloxane, KH-550 silane coupling 20g of the agent, heated to 100°C, stirred and mixed evenly. Subsequently, 1 g of dibutyltin dilaurate as a catalyst was added, and the stirring reaction was continued for 2 h to obtain a compatibilizer. Add bisphenol E type cyanate 240g subsequently, continue stirring reaction 1h. The obtained prepreg is vacuum-extracted to remove air bubbles, then poured into the mold under normal pressure, and finally cured according to the curing process 120°C / 4h+150°C / 2h+170°C / 2h to obtain toughened hydroxyl-terminated polydimethylsiloxane Cyanate resin based shape memory materials.

[0033] The compatibilizer was prepared by hydroxyl-terminated polydimethylsiloxane, KH-550 silane coupling agent and AL-3040 epoxy resin. Utilize the good compatibility between AL-3040 e...

Embodiment 2

[0037] The preparation method of polysiloxane-modified cyanate resin-based shape memory material is as follows: weigh 66.7g of AL-3040 epoxy resin, 80g of hydroxyl-terminated polydimethylsiloxane, KH-550 silane dimethicone according to the above mass fractions. 13.3g of the joint agent, heated to 100°C, stirred and mixed evenly. Subsequently, 0.67 g of dibutyltin dilaurate as a catalyst was added, and the stirring reaction was continued for 2 h to obtain a compatibilizer. Subsequently, 240 g of bisphenol E type cyanate was added, and the stirring reaction was continued for 1 h. The obtained prepreg is vacuum-extracted to remove air bubbles, then poured into the mold under normal pressure, and finally cured according to the curing process 120°C / 4h+150°C / 2h+170°C / 2h to obtain toughened hydroxyl-terminated polydimethylsiloxane Cyanate resin based shape memory materials.

[0038] The content of the compatibilizer in the toughened and modified cyanate resin-based shape memory mat...

Embodiment 3

[0041] The preparation method of polysiloxane-modified cyanate resin-based shape memory material is as follows: weigh 50 g of AL-3040 epoxy resin, 60 g of hydroxyl-terminated polydimethylsiloxane, KH-550 silane coupling 10g of the agent, heated to 100°C and then stirred and mixed evenly. Subsequently, 0.5 g of dibutyltin dilaurate as a catalyst was added, and the stirring reaction was continued for 2 h to obtain a compatibilizer. Add bisphenol E type cyanate 240g subsequently, continue stirring reaction 1h. The obtained prepreg is vacuum-extracted to remove air bubbles, then poured into the mold under normal pressure, and finally cured according to the curing process 120°C / 4h+150°C / 2h+170°C / 2h to obtain toughened hydroxyl-terminated polydimethylsiloxane Cyanate resin based shape memory materials.

[0042] The content of the compatibilizer in the toughened and modified cyanate resin-based shape memory material obtained by the hydroxyl-terminated polydimethylsiloxane obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com