Manufacturing method of annular seam structure of water storage tank

A manufacturing method and a technology of a water storage tank, which are applied to steam boiler components, steam boiler accessories, lighting and heating equipment, etc., can solve the problems of large wall thickness margin, thin inner surface wall thickness, and single manufacturing method of the water storage tank. problem, to achieve the effect of improving the quality and economic benefits of the circular joint, reducing the positive deviation of the wall thickness, and reducing the consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

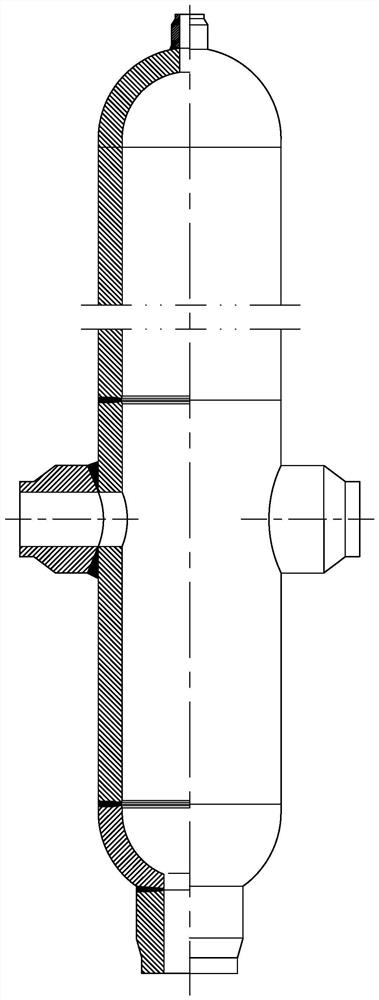

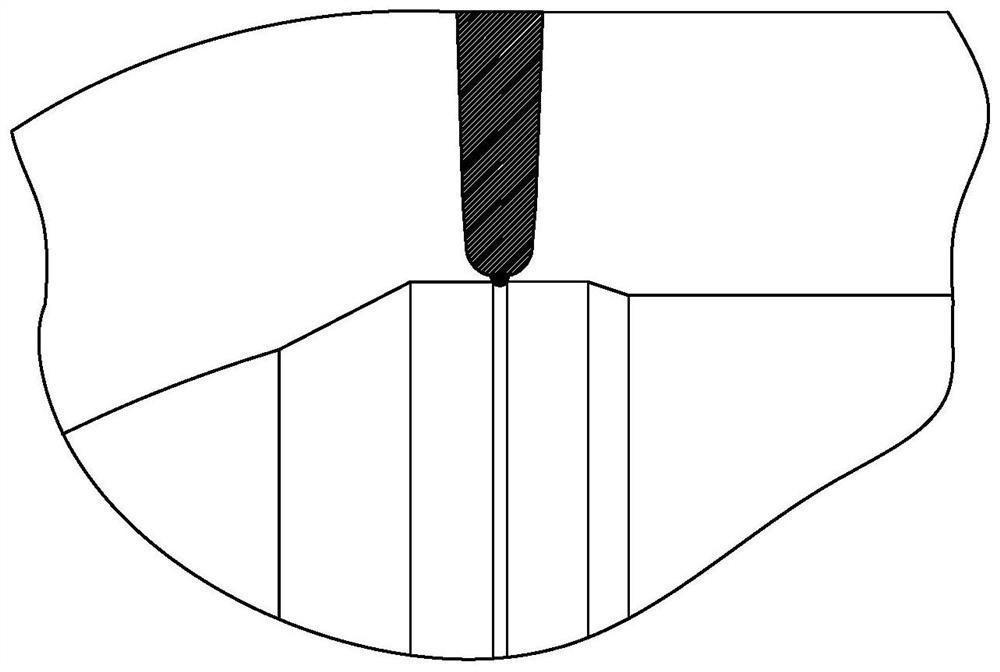

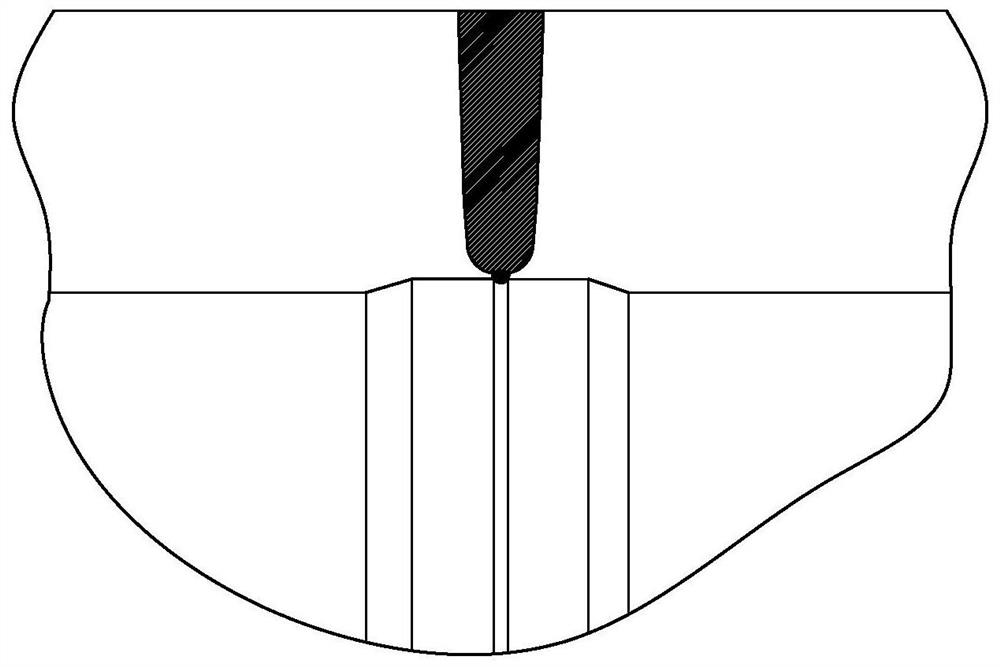

[0043] Specific implementation mode one: combine Figure 4 and Figure 5 Describe this embodiment, the annular seam structure of the water storage tank in this embodiment, the water storage tank includes two seal heads 2 and several cylinder sections 1, all the cylinder sections 1 are spliced in sequence along their axes to form a cylinder body, and the two seal heads 2 are respectively arranged at both ends of the cylinder body, the ellipticity of the cylinder body and the head 2 is ±0.6mm, and the thickness deviation of the cylinder body and the head 2 is 0-2mm; there is a butt joint between two adjacent cylinder sections 1 Circumferential groove 3, the butt ring groove 3 between each cylinder section 1 and the adjacent cylinder section 1 is connected by welding, and each head 2 and the adjacent cylinder section 1 are provided with The butt ring seam groove 3, the butt ring seam groove 3 between the head 2 and the cylinder section is connected by welding.

[0044] The he...

specific Embodiment approach 2

[0045] Specific implementation mode two: combination Figure 4 and Figure 5 To describe this embodiment, the barrel joint 1 of this embodiment is a forging or a large-diameter thick-walled seamless steel pipe whose inner and outer surfaces have been machined and finely ground. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific implementation mode three: combination Figure 4 and Figure 5 The present embodiment will be described. In this embodiment, the outer diameter of the cylindrical joint 1 is 600 to 1200 mm, and the wall thickness of the cylindrical joint 1 is 60 to 160 mm. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com