Novel glass reinforced plastic cooling tower

A glass fiber reinforced plastic and cooling tower technology, which is applied in the field of cooling towers, can solve the problem of insufficient cooling efficiency of cooling towers, and achieve the effects of accelerating heat loss, saving water replenishment, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

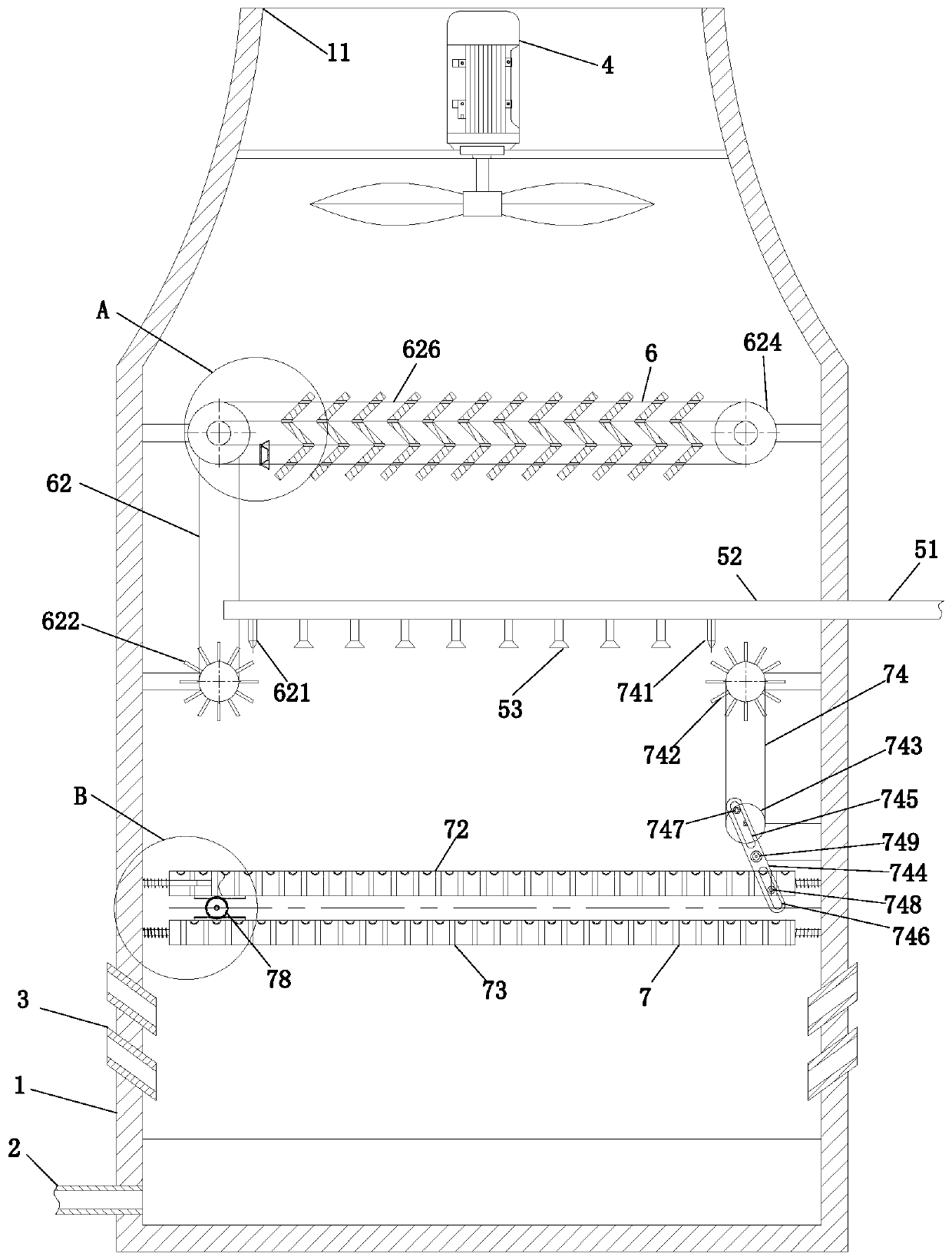

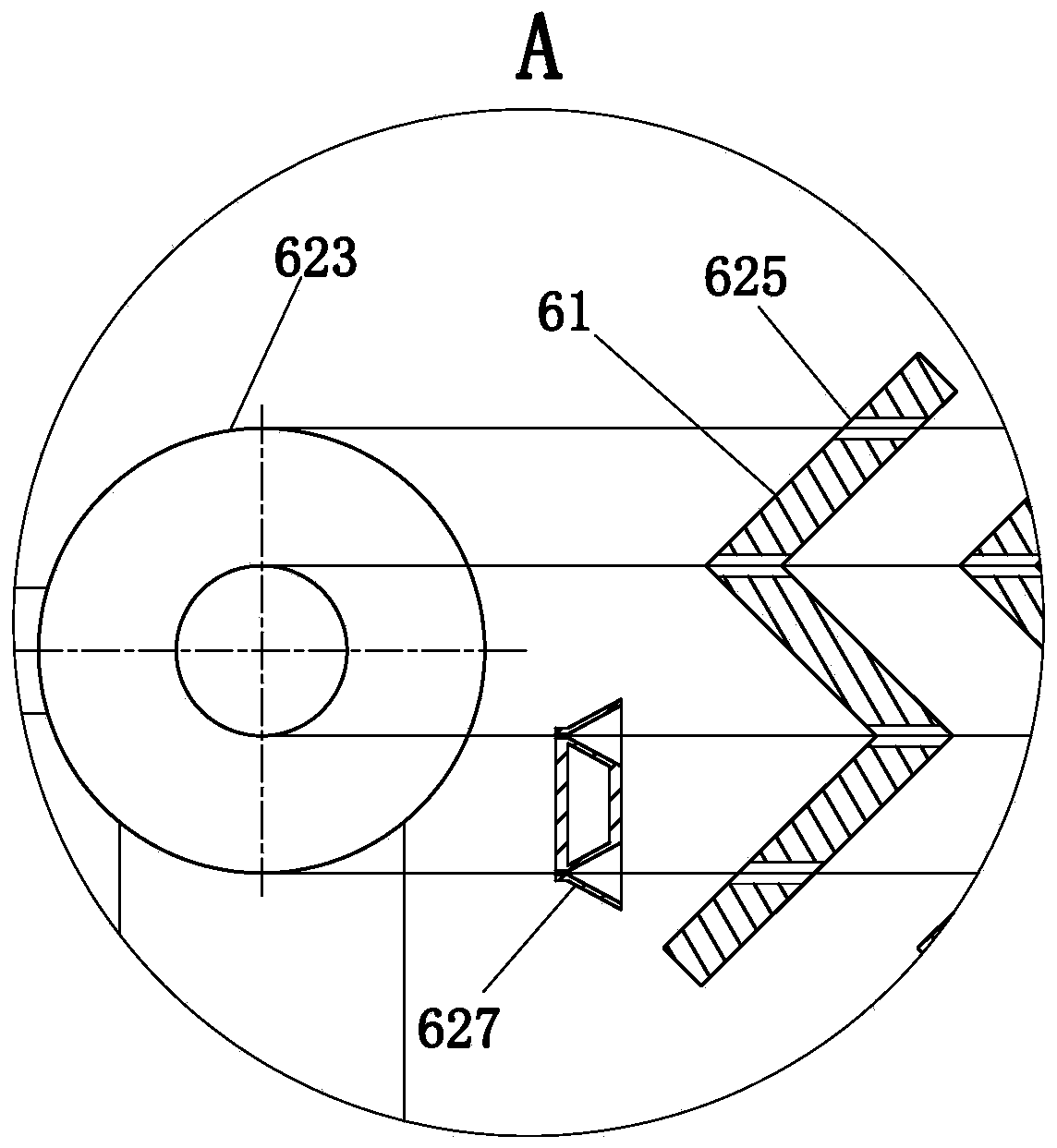

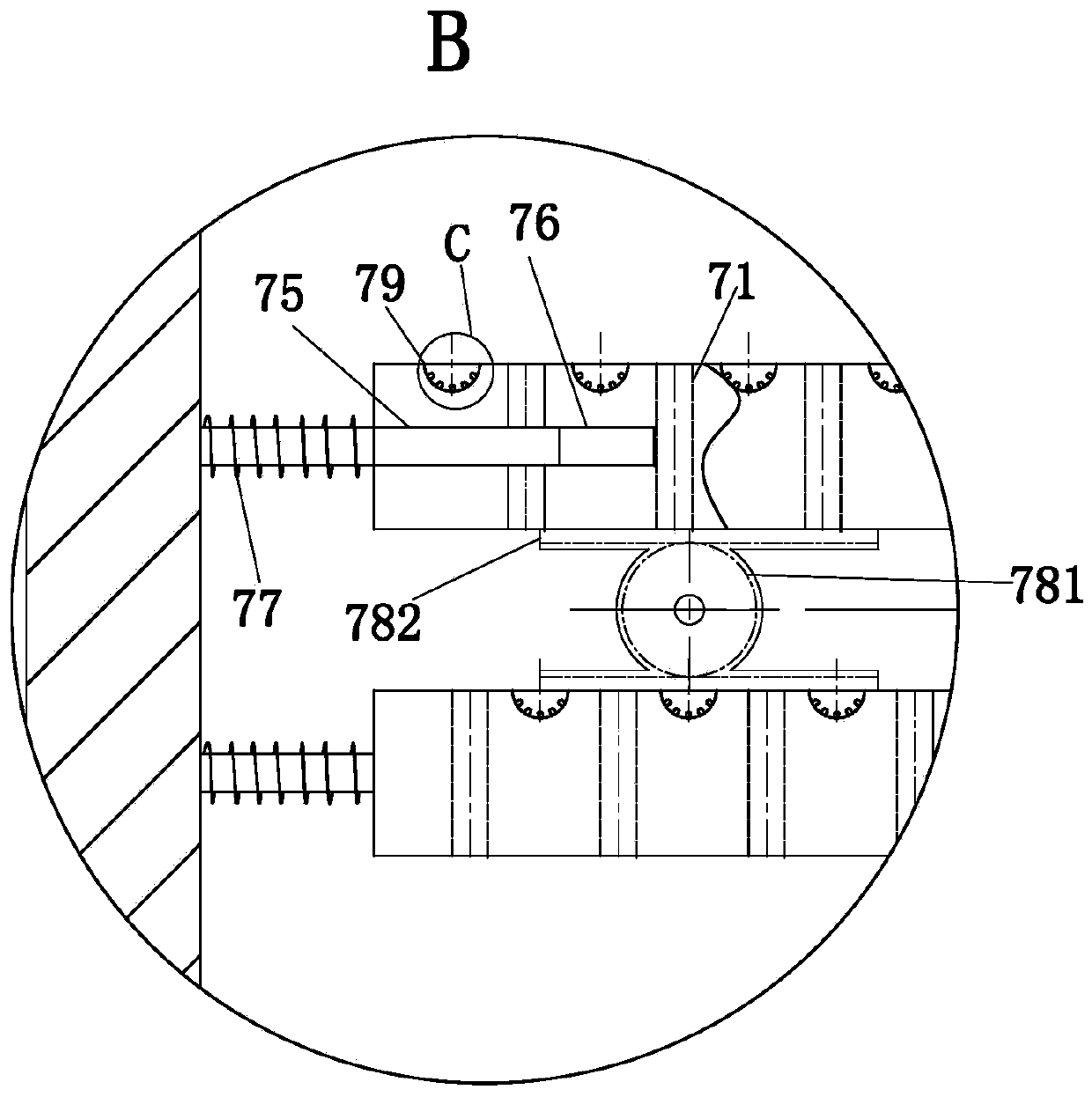

[0026] As an embodiment of the present invention, a second driving assembly 62 is provided on the left side of the water blocking unit 6, and the second driving assembly 62 includes a second nozzle 621, a second water wheel 622, a second driving wheel 623 and Tensioner 624, the left side of the glass fiber reinforced plastic water retaining plate 61 is provided with a second drive wheel 623, the right side of the glass fiber reinforced plastic water retaining plate 61 is provided with a tensioning wheel 624 at a symmetrical position with the second driving wheel 623, and on the glass fiber reinforced plastic water retaining plate 61 There are several thread holes 625, and water-absorbing cotton thread 626 is passed through the thread-passing holes 625, and the water-absorbing cotton thread 626 passes through the thread-passing holes 625 on the glass fiber reinforced plastic water retaining plate 61 and then winds around the tension wheel 624 and the second driving wheel 623 Abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com