Enhanced gas diffusion layer microporous membrane for fuel cell membrane electrode, membrane electrode and preparation method thereof

A fuel cell membrane and gas diffusion layer technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems affecting the durability of membrane electrodes and the complexity of the catalyst coating process, so that the coating process is simple and easy to ensure that the electrical Chemical performance, easy industrialization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

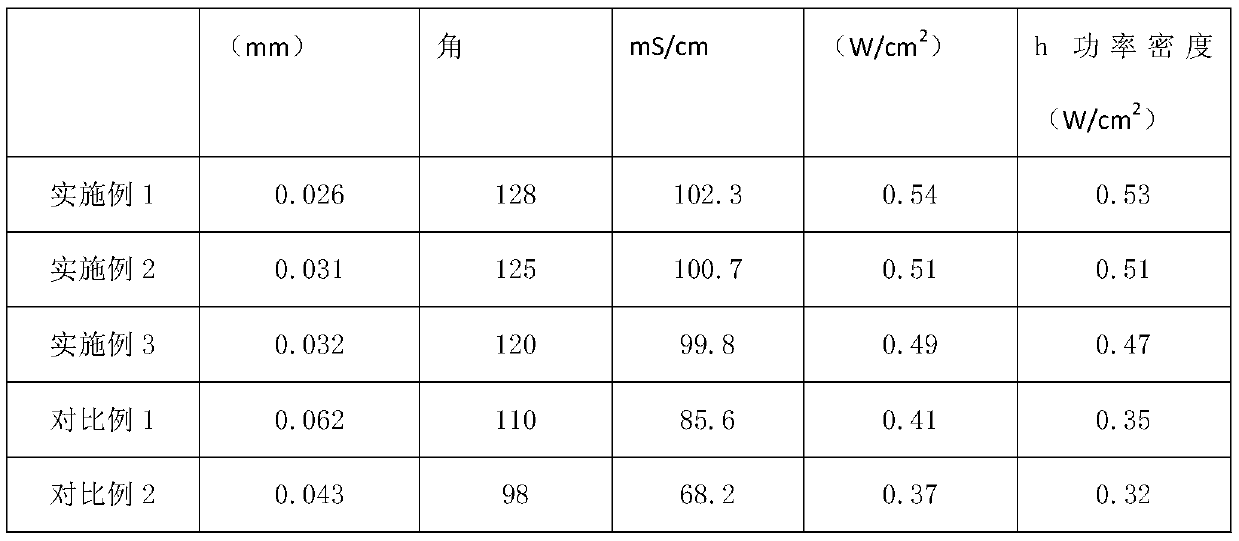

Embodiment 1

[0028] Add polytetrafluoroethylene emulsion and conductive carbon black into ethanol and ultrasonically disperse for 30 minutes, then heat and coagulate in an 80-degree water bath for 20 minutes to obtain a viscous slurry. In the slurry raw materials, 50 parts by weight of carbon powder, mass Concentration is 30 parts by weight of polytetrafluoroethylene emulsion of 60%, 20 parts by weight of absolute ethanol;

[0029] The viscous slurry obtained in step (1) is mixed with a plasticizer, 96 parts by weight of the slurry, 4 parts by weight of the plasticizer, the plasticizer is toluene, mechanically stirred for 10 minutes, and a film is prepared by rolling technology;

[0030] After drying at room temperature, bake at 240 degrees for 30 minutes, and bake at 340 degrees for 30 minutes to obtain a fuel cell-enhanced gas diffusion layer microporous membrane;

[0031] Use screen printing technology to prepare a Pt / C catalytic layer on one side of the microporous membrane, and prepar...

Embodiment 2

[0035] Add polytetrafluoroethylene emulsion and graphene to ethanol and ultrasonically disperse for 30 minutes, then heat and coagulate in an 80-degree water bath for 16 minutes to obtain a viscous slurry. In the slurry raw materials, 56 parts by weight of graphene, mass concentration 28 parts by weight of 60% polytetrafluoroethylene emulsion, 16 parts by weight of absolute ethanol;

[0036] Mix the viscous slurry obtained in step (1) with a plasticizer, 95 parts by weight of the slurry, 5 parts by weight of the plasticizer, the plasticizer is phenol, mechanically stirred for 10 minutes, and the film is prepared by wet stretching technology ;

[0037] After drying at room temperature, bake at 250 degrees for 25 minutes, and bake at 350 degrees for 25 minutes to obtain a fuel cell-enhanced gas diffusion layer microporous membrane;

[0038] Electrostatic spraying technology is used to prepare a Pt / C catalytic layer on one side of the microporous membrane to prepare a microporou...

Embodiment 3

[0042] Add polytetrafluoroethylene emulsion and carbon nanotubes to ethanol and ultrasonically disperse them for 20 minutes, then heat and coagulate in an 80-degree water bath for 10 minutes to obtain a viscous slurry. Among the slurry raw materials, 62 parts by weight of carbon nanotubes, 25 parts by weight of polytetrafluoroethylene emulsion with a mass concentration of 60%, and 13 parts by weight of absolute ethanol;

[0043] The viscous slurry obtained in step (1) is mixed with a plasticizer, 98 parts by weight of the slurry, 2 parts by weight of a plasticizer, and the plasticizer is cyclohexanone, mechanically stirred for 20 minutes, and wet stretching technology is adopted Prepare thin film;

[0044] After drying at room temperature, bake at 250 degrees for 25 minutes, and bake at 350 degrees for 25 minutes to obtain a fuel cell-enhanced gas diffusion layer microporous membrane;

[0045] Electrostatic spraying technology is used to prepare a catalytic layer Pt / C on one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com