A method for ultrasonically assisted extraction of ammonium perchlorate in scrapped four-component htpb propellant

An ultrasonic-assisted extraction, ammonium perchlorate technology, applied in perchloric acid, perchlorate, chemical instruments and methods, etc., can solve the problems of unstable chemical properties, poor propellant swelling, general extraction effect, etc. The operation method is simple and easy, solve the difficulty of swelling, and the effect of safe and efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

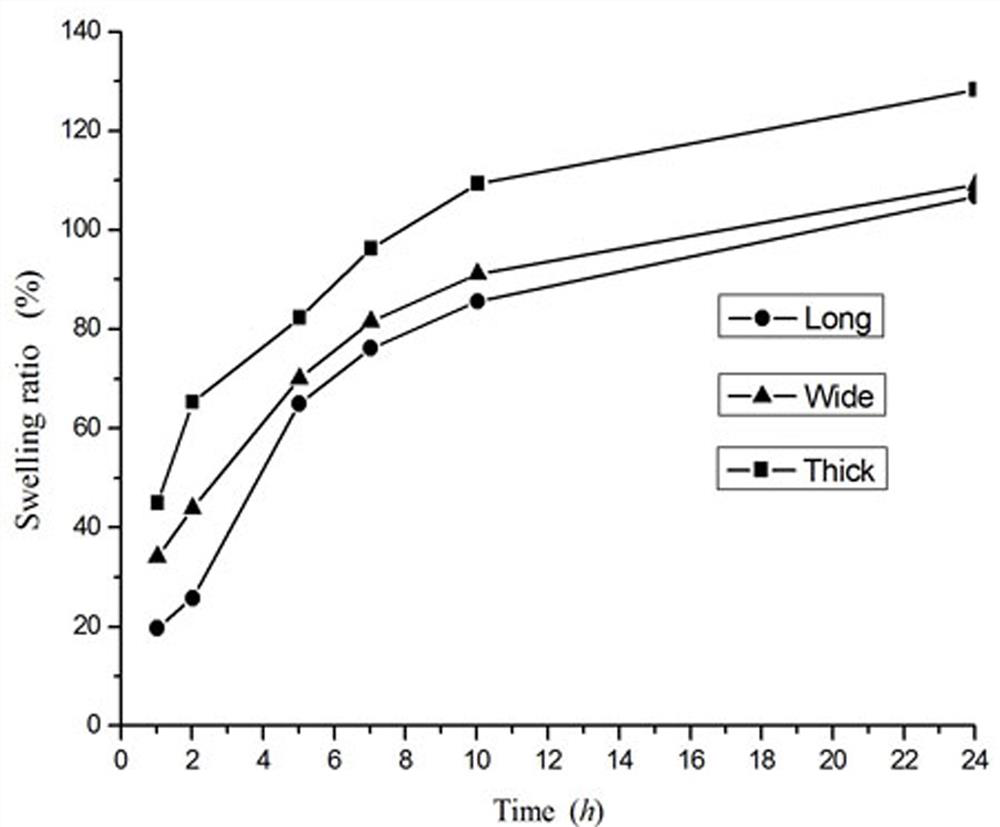

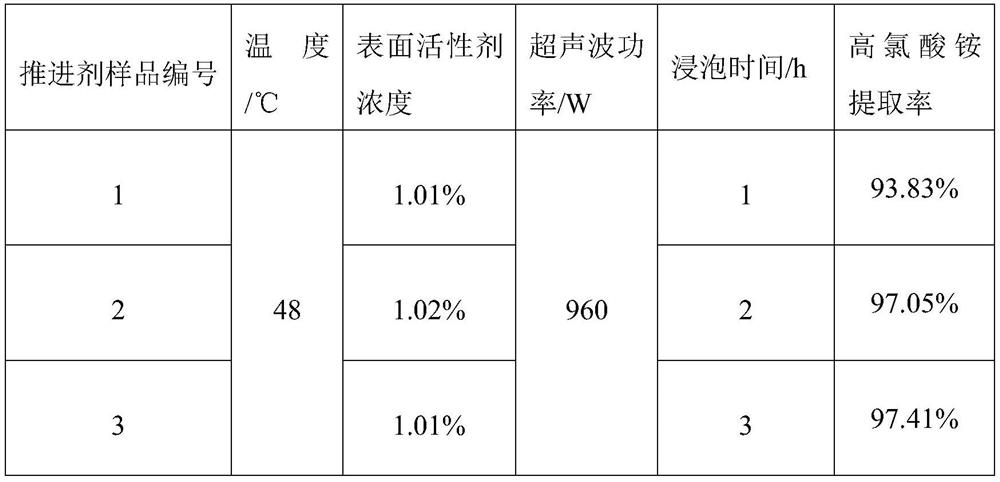

[0026] A method for ultrasonically assisted extraction of ammonium perchlorate in scrapped four-component HTPB propellant, comprising the following steps: safely crushing the four-component HTPB propellant, the initial size of the broken propellant sample is 10mm×5mm×3mm; Put the propellant in the Erlenmeyer flask, add petroleum ether, soak for 3 minutes, wash with ultrasonic power of 720W for 3 minutes, and wash 3 times. After cleaning, 5g of the propellant was soaked and swelled in 90ml of a mixed solution of water: absolute ethanol: petroleum ether with a volume ratio of 1:1:1 for 24 hours, and the temperature of the solution was 33°C. Then suction filtration, after cleaning the swollen propellant particles with distilled water, add distilled water, the mass ratio of propellant to distilled water is 1:10, and add the sodium dodecylbenzenesulfonate surface active agent that accounts for 1% of the mass fraction of distilled water. Stir on a constant temperature magnetic stirr...

Embodiment 2

[0029] A method for ultrasonically assisted extraction of ammonium perchlorate in scrapped four-component HTPB propellant, comprising the steps of: safely crushing the four-component HTPB propellant, the size of the broken propellant sample is less than 4mm; placing 10g of the propellant in a cone In a shaped bottle, add petroleum ether, soak for 3 minutes, and clean with an ultrasonic power of 720W for 3 minutes for 3 times. After cleaning, the propellant is soaked and swelled for 10 hours in 180ml of a mixed solution of water: absolute ethanol: petroleum ether with a volume ratio of 1:1:1, and the temperature of the solution is 48°C. Then suction filtration, after cleaning the swollen propellant particles with distilled water, add distilled water, the mass ratio of propellant to distilled water is 1:10, and add the sodium dodecylbenzenesulfonate surface active agent that accounts for 1% of the mass fraction of distilled water. Stir on a constant temperature magnetic stirrer ...

Embodiment 3

[0035]A method for ultrasonically assisted extraction of ammonium perchlorate in scrapped four-component HTPB propellant, comprising the steps of: safely crushing the four-component HTPB propellant, the size of the broken propellant sample is less than 4mm; placing 5g of the propellant in a cone In a shaped bottle, add petroleum ether, soak for 3 minutes, and clean with an ultrasonic power of 720W for 3 minutes for 3 times. After cleaning, 5g of the propellant was soaked and swelled for 12 hours in 90ml of a mixed solution of water: absolute ethanol: petroleum ether with a volume ratio of 1:1:1, and the temperature of the solution was 41°C. Then suction filter, wash the swollen propellant particles with distilled water, add distilled water, the mass ratio of propellant to distilled water is 1:15, add 1.5% sodium dodecylbenzenesulfonate surfactant, and the rotating speed is 500r It was stirred on a constant temperature magnetic stirrer for 1 hour, then soaked and extracted for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com