Lithium disilicate microglass fiber and preparation method thereof

A lithium disilicate, glass fiber technology, applied in the direction of glass manufacturing equipment, manufacturing tools, etc., can solve the influence of semi-permeability that is not clearly mentioned, the light transmittance of lithium disilicate glass ceramics is reduced, and the appearance of teeth is difficult to natural. Comparing with other problems, to achieve the effect of low cost, improved mechanical properties and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

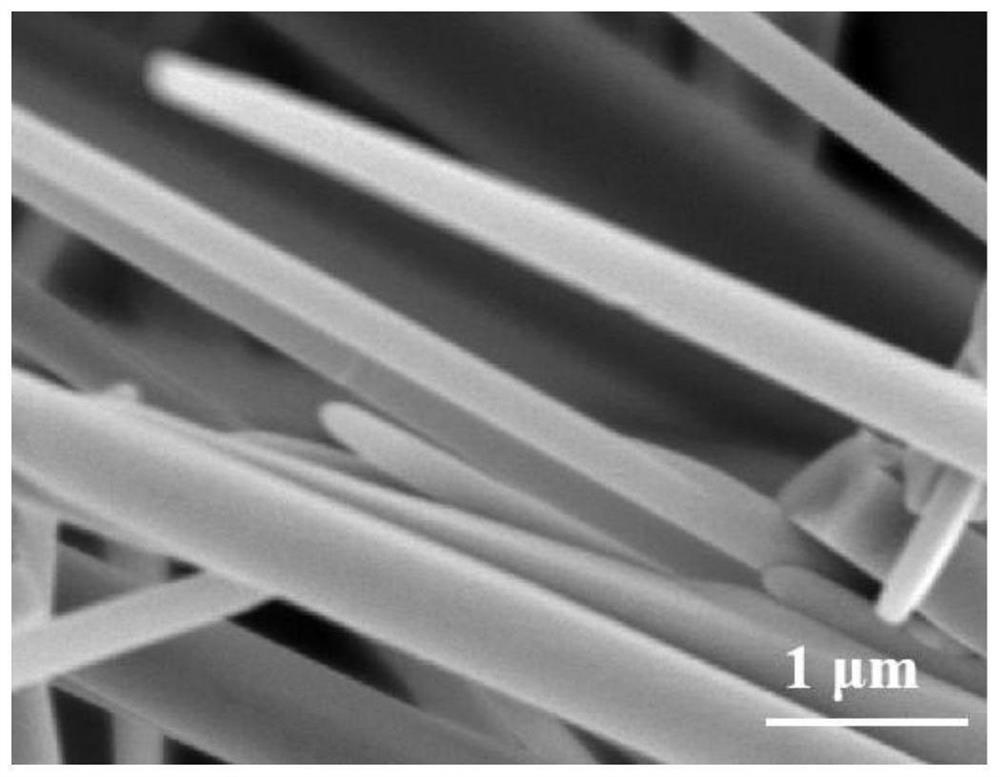

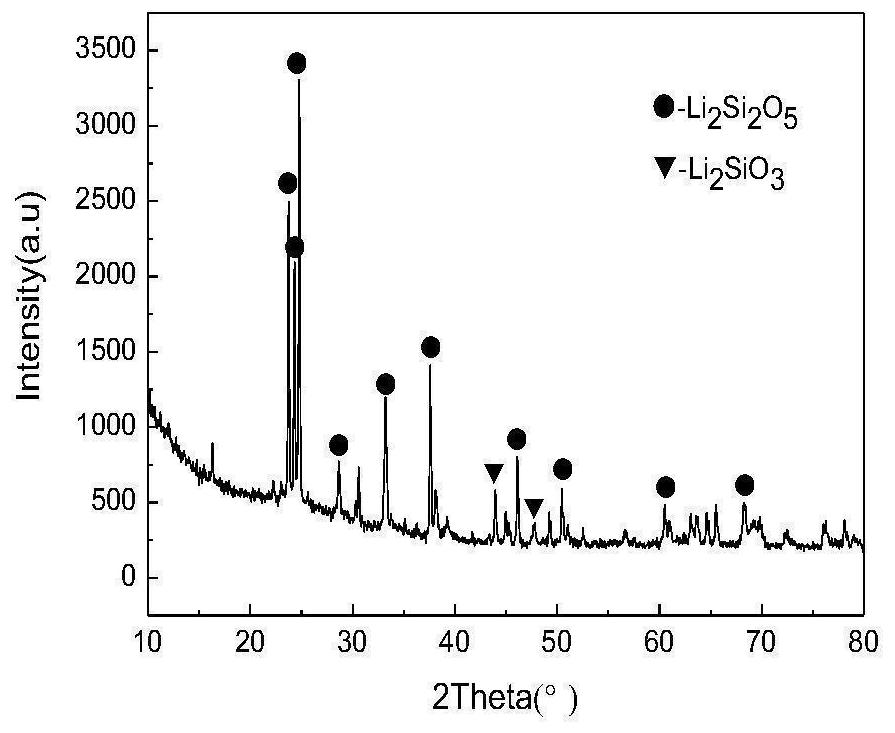

[0027] A preparation method of lithium disilicate glass-ceramic fiber, comprising the following steps:

[0028] (1) Take tetraethyl orthosilicate (TEOS) as silicon source and add in dehydrated alcohol, obtain A solution after dissolving;

[0029] (2) Lithium acetate was taken as lithium source and dissolved in deionized water to obtain solution B; the molar ratio of lithium source and silicon source was always kept at 1:1.

[0030] (3) Mix the A solution prepared in step (1) with the B solution prepared in step (2), stir, slowly add ammonia water to adjust the pH value, and slowly add the spinning aid polyvinyl alcohol dropwise, stir at room temperature for 2-8 Obtain the precursor sol in 1 hour, wherein the addition of polyvinyl alcohol is 5~15% of the quality of the precursor sol;

[0031] (4) Concentrating the precursor sol in step (3) in a water bath at 20-70°C to the sol to be spun;

[0032] (5) the sol to be spun in step (4) is spun by electrospinning equipment to obta...

Embodiment 1

[0036] (1) Take 2g of absolute ethanol in a beaker, add 9g of TEOS, and stir magnetically at room temperature for 10 minutes to obtain A solution;

[0037] (2) Take 2.85g of lithium acetate as a lithium source and dissolve it in 3.1g of deionized water, and stir it with a magnetic stirrer for 3 minutes to obtain solution B; the molar ratio of lithium source and silicon source is always kept at 1:1.

[0038] (3) Mix A solution and B solution, stir, slowly add ammonia water to adjust the pH value to 7, and slowly add spinning aid polyvinyl alcohol, and stir at room temperature for 5 hours to obtain a uniform slightly white precursor sol, wherein , the addition of polyvinyl alcohol is 10% of the mass of the mixed sol; the degree of polymerization of polyvinyl alcohol is 2000, and the degree of alcoholysis is 50%.

[0039] (4) Concentrate the precursor sol in a water bath at 50° C. to the sol to be spun; the concentration time is 36 hours, and it is aged at room temperature until ...

Embodiment 2

[0043] (1) Take 2g of absolute ethanol in a beaker, add 9g of TEOS, and stir magnetically at room temperature for 10 minutes to obtain A solution;

[0044] (2) Take 2.85g of lithium acetate as a lithium source and dissolve it in 3.1g of deionized water, and stir it with a magnetic stirrer for 5 minutes to obtain solution B; the molar ratio of lithium source and silicon source is always kept at 1:1.

[0045] (3) Mix A solution and B solution, stir, slowly add ammonia water to adjust the pH value to 5, and slowly add spinning aid polyvinyl alcohol, and stir at room temperature for 2 hours to obtain a uniform slightly white precursor sol, wherein , the addition of polyvinyl alcohol is 5% of the mass of the mixed sol; the degree of polymerization of polyvinyl alcohol is 1500, and the degree of alcoholysis is 45%.

[0046] (4) Stir and concentrate the precursor sol at 20° C. to the sol to be spun; the concentration time is 72 hours, and it is aged at room temperature until the viscos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com