Phosphogypsum lightweight concrete and preparation method thereof

A light-weight concrete and phosphogypsum technology, which is applied in the field of comprehensive utilization of phosphogypsum, can solve the problems of weakening the bonding force between gypsum grains, reducing strength, and complex processes, etc., and achieve low macroscopic strength, suppressing alternating changes in cold and heat, and enhancing The effect of durability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

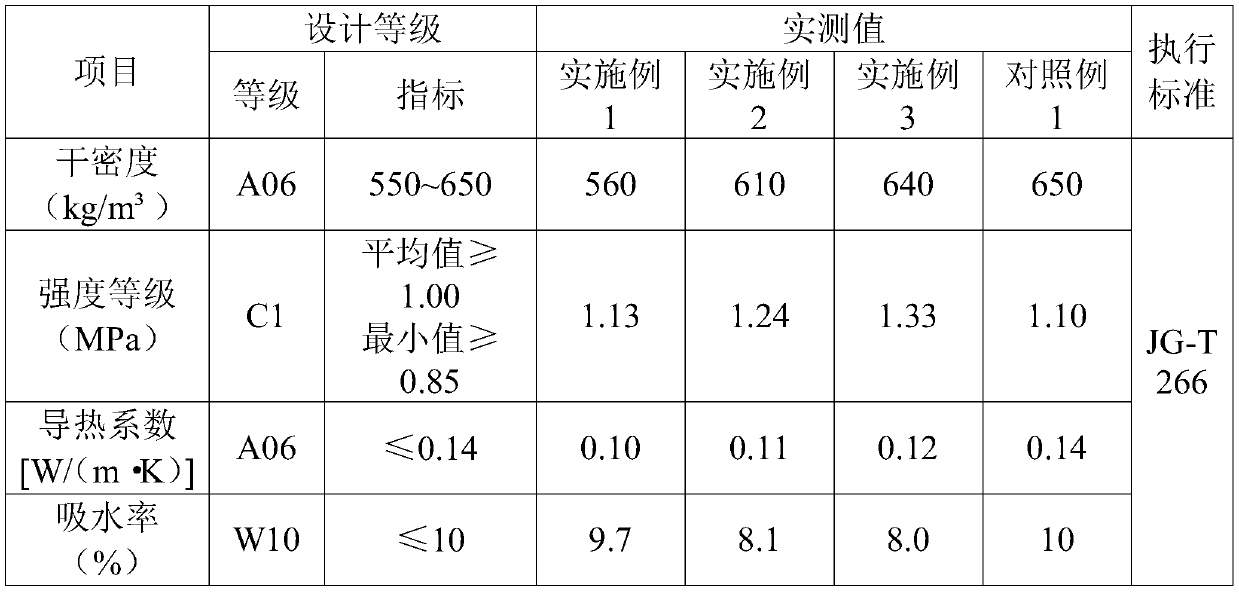

Examples

Embodiment 1

[0022] (1) Weighing, dry mixing, weighing 300 parts of phosphogypsum, 400 parts of cement, 100 parts of admixture, 5 parts of quicklime, 2 parts of inorganic mineral additives, 2 parts of admixture, dry mixing in a mixer for 20-30s, Make the material evenly dispersed;

[0023] (2) Add water and admixture to stir, add 900 parts of water, add the admixture to the powder after being diluted with water, stir slowly for 1 minute, stir quickly for 2 minutes, and let stand;

[0024] (3) The foaming agent is diluted and foamed, and the foaming agent is diluted with 60 times of water, added to the prepared slurry, and stirred rapidly for 1 min;

[0025] (4) Injection molding, the mixed foam concrete is quickly injected into the mold for molding.

Embodiment 2

[0027] (1) Weighing, dry mixing, weighing 300 parts of phosphogypsum, 300 parts of cement, 80 parts of admixture, 5 parts of quicklime, 3 parts of inorganic mineral additives, 2 parts of admixture, dry mixing in a mixer for 20-30s, Make the material evenly dispersed;

[0028] (2) Add water and admixture to stir, add 850 parts of water, add the admixture to the powder after being diluted with water, stir slowly for 1 minute, stir quickly for 2 minutes, and let stand;

[0029] (3) The foaming agent is diluted and foamed, and the foaming agent is diluted with 60 times of water, added to the prepared slurry, and stirred rapidly for 1 min;

[0030] (4) Injection molding, the mixed foam concrete is quickly injected into the mold for molding.

Embodiment 3

[0032] (1) Weighing and dry mixing, weigh 350 parts of phosphogypsum, 300 parts of cement, 90 parts of admixtures, 6 parts of quicklime, 2.5 parts of inorganic mineral additives, 2.1 parts of admixtures, and dry mix them in a mixer for 30 seconds to make the materials Evenly dispersed;

[0033] (2) Add water and admixture to stir, add 840 parts of water, add the admixture to the powder after being diluted with water, stir slowly for 1 minute, stir quickly for 2 minutes, and let stand;

[0034] (3) The foaming agent is diluted and foamed, and the foaming agent is diluted with 60 times of water, added to the prepared slurry, and stirred rapidly for 1 min;

[0035] (4) Injection molding, the mixed foam concrete is quickly injected into the mold for molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com