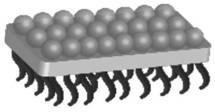

Novel organic-inorganic hybrid sheet Janus heat conducting filler and preparation method thereof

A thermally conductive filler and organic technology, applied in the field of sheet-like Janus thermally conductive fillers and their preparation, can solve problems such as unreported application of thermally conductive fillers, and achieve the effects of improving dispersion and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

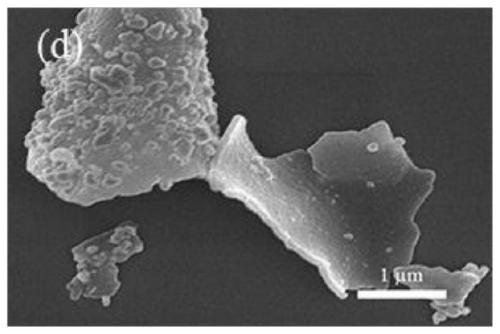

[0020] 1) The mass ratio is 0.1% of SiO with hydroxyl groups on the inside and amino groups on the outside 2 Hollow spheres (hollow spheres with a diameter of 5 μm and a wall thickness of 15 nm) are dispersed in deionized water;

[0021] 2) Continue to dissolve silver nitrate and PVP with a mass ratio of 1:1 in the dispersion of hollow spheres, and add ascorbic acid (with Ag + The molar ratio is 2), the Ag + Reducted into Ag, and deposited on the surface of the silica hollow sphere, the hollow sphere with Ag nanoparticles deposited on the surface was obtained, and its intrinsic thermal conductivity was measured to be 110 (W / mK);

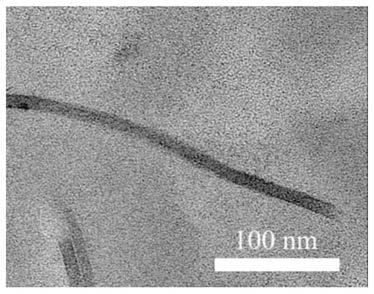

[0022] 3) The prepared hollow spheres deposited with Ag are crushed into nanosheets with a sheet diameter of 0.5-2 μm, and the hydroxyl groups inside the hollow spheres are exposed to obtain the intermediate product Ag-J-OH Janus sheets;

[0023] 4) Disperse Ag-J-OH Janus tablets in toluene, add silane coupling agent, 4-chloromethylphenyltrimethoxy...

Embodiment 2

[0027] 1) The mass ratio is 0.1% of SiO with hydroxyl groups on the inside and amino groups on the outside 2 Hollow spheres (hollow spheres with a diameter of 5 μm and a wall thickness of 15 nm) are dispersed in deionized water;

[0028] 2) Continue to dissolve silver nitrate and PVP with a mass ratio of 2:1 in the dispersion liquid of the hollow sphere, and add ascorbic acid (the molar ratio to Ag+ is 2) under high-speed stirring, and the Ag+ + It is reduced to Ag and deposited on the surface of the silica hollow sphere to obtain a hollow sphere with Ag nanoparticles deposited on the surface, and its intrinsic thermal conductivity is measured to be 160 (W / mK);

[0029] 3) The prepared hollow spheres deposited with Ag are crushed into nanosheets with a sheet diameter of 0.5-2 μm, and the hydroxyl groups inside the hollow spheres are exposed to obtain the intermediate product Ag-J-OH Janus sheets;

[0030] 4) Disperse Ag-J-OH Janus tablets in toluene, add silane coupling agent...

Embodiment 3

[0034] 1) The mass ratio is 0.1% of SiO with hydroxyl groups on the inside and amino groups on the outside 2 Hollow spheres (hollow sphere diameter is 7μm, wall thickness is 20nm) dispersed in deionized water;

[0035] 2) Continue to dissolve copper sulfate and CTAB with a mass ratio of 1:1 in the dispersion of hollow spheres, and add ascorbic acid (with Cu 2+ The molar ratio is 4), the Cu 2+ Reducted into Cu, and deposited on the surface of the silica hollow sphere, the hollow sphere with Cu nanoparticles deposited on the surface was obtained, and its intrinsic thermal conductivity was measured to be 52 (W / mK);

[0036] 3) Pulverize the prepared Cu-deposited hollow spheres into nanosheets with a sheet diameter of 2 μm, so that the hydroxyl groups inside the hollow spheres are exposed, and the intermediate product Cu-J-OH Janus sheets are obtained;

[0037] 4) Disperse Cu-J-OH Janus tablets in toluene, add silane coupling agent, bromophenyltrimethoxysilane, and react in an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com