Fabrication process and application of a vertical-heterodomain organic spintronic device

A technology of spintronic devices and preparation process, applied in the field of spintronics, can solve problems such as uncontrollable effective length, low device repetition rate, complex interface, etc., and achieve the effect of avoiding electrical short circuit and avoiding electrical short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

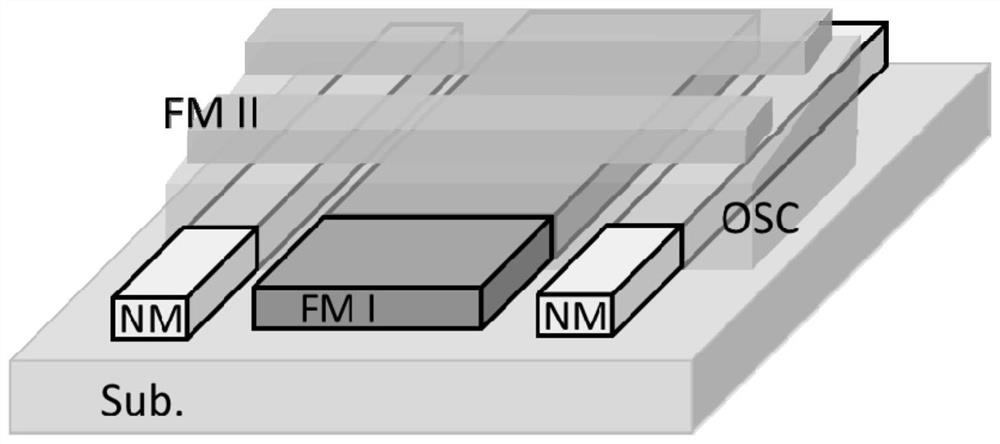

Method used

Image

Examples

Embodiment 1

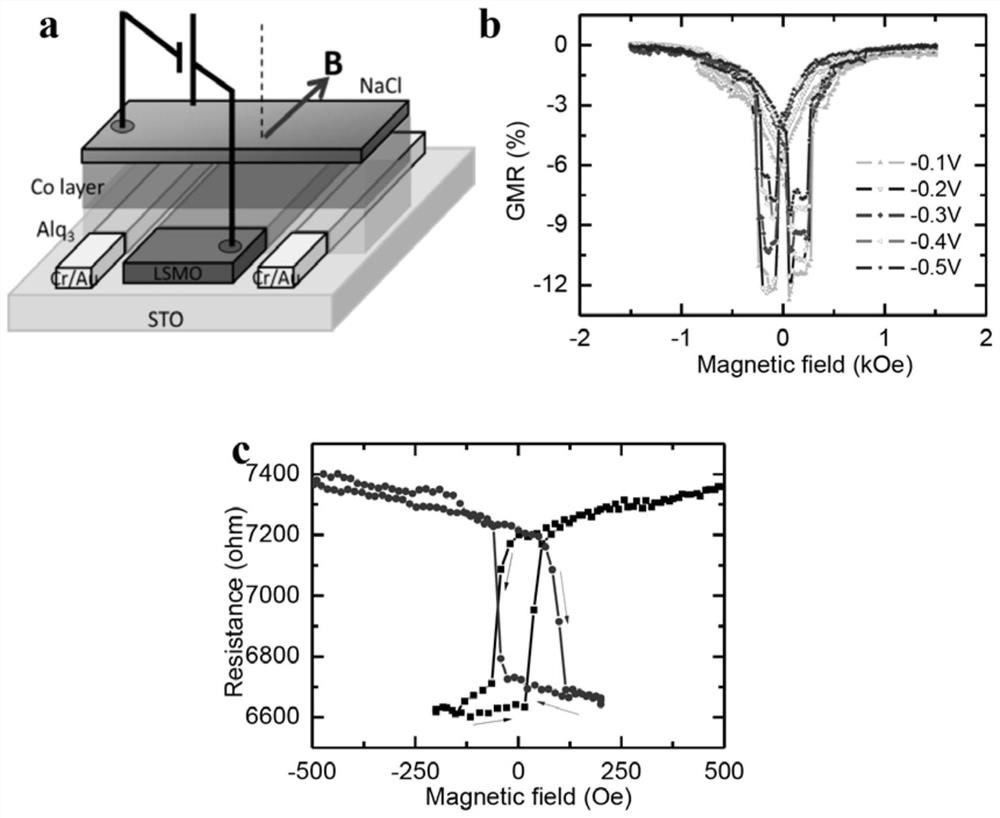

[0036] Using single crystal SrTiO 3 substrate, epitaxially grow a single crystal LSMO film with a thickness of 30nm on its surface, and optically etch it into a 50 micron wide strip electrode; then use the optical overlay method to grow Cr (5nm ) / Au(25nm) strip electrode; using ultra-high vacuum thermal evaporation to grow wedge-shaped organic layer Alq on the surface of LSMO and Cr / Au electrode 3 , the thickness of the wedge-shaped organic layer is 10-100nm, and the thickness of the wedge-shaped organic layer changes continuously along the direction of the LSMO strip electrode. The thinnest part is 10nm, and the thickest part is 100nm; A Co electrode with a thickness of 15nm is used, and a physical mask is used to realize the in-situ forming of the strip electrode. The direction is perpendicular to the LSMO electrode, and a NaCl protective layer is grown on the surface of the Co strip electrode.

[0037] The vertical-heterogeneous organic spintronic device prepared in this e...

Embodiment 2

[0040] Using single crystal SrTiO 3 substrate, epitaxially grow a single crystal LSMO film with a thickness of 30nm on its surface, and optically etch it into a 50 micron wide strip electrode; then use the optical overlay method to grow Cr (5nm ) / Au(25nm) strip electrode; using ultra-high vacuum thermal evaporation to grow wedge-shaped organic layer Alq on the surface of LSMO and Cr / Au electrode 3 , the thickness of the wedge-shaped organic layer is 10-100nm, and the thickness of the wedge-shaped organic layer changes continuously along the direction of the LSMO strip electrode. The thinnest part is 10nm, and the thickest part is 100nm; A Co electrode with a thickness of 15nm is used, and a physical mask is used to realize the in-situ forming of the strip electrode. The direction is perpendicular to the LSMO electrode, and a NaCl protective layer is grown on the surface of the Co strip electrode.

[0041] By applying a voltage between LSMO-Cr / Au, a spin-polarized current is i...

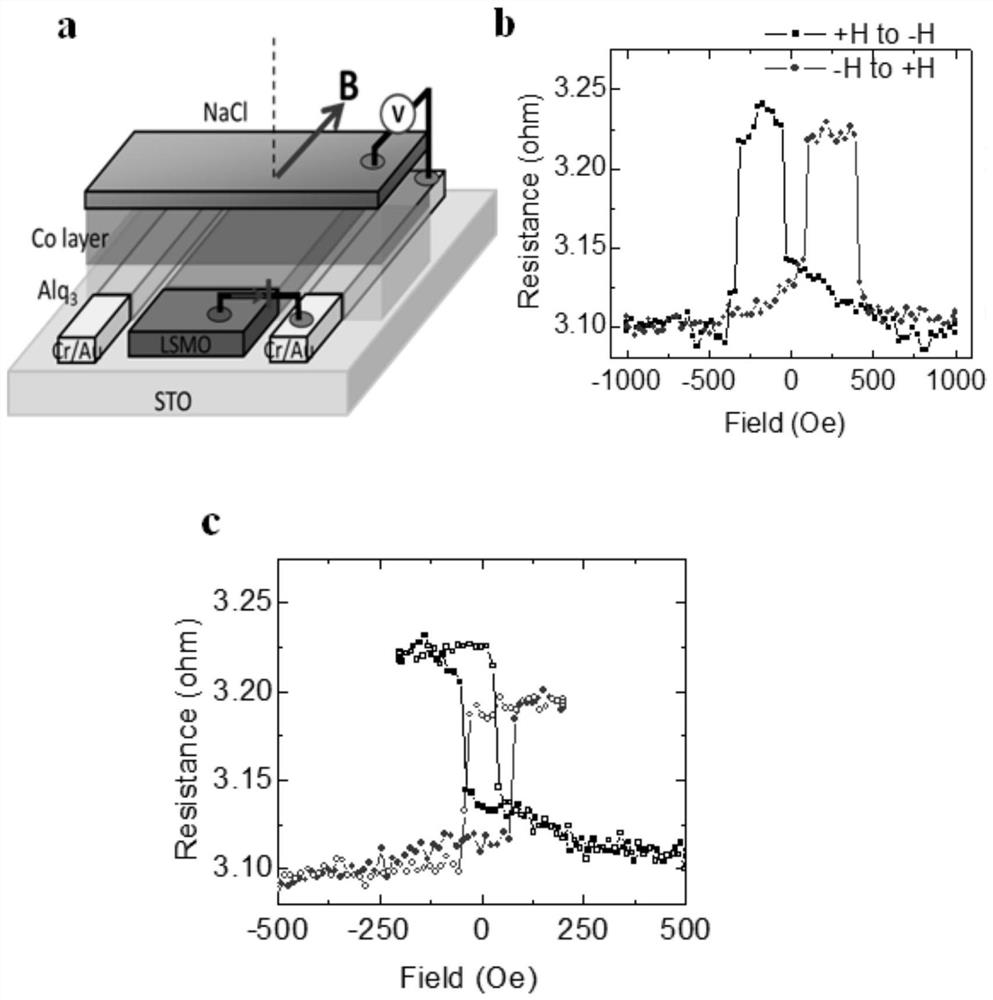

Embodiment 3

[0043] Using single crystal SrTiO 3 substrate, epitaxially grow a single crystal LSMO film with a thickness of 30nm on its surface, and optically etch it into a 50 micron wide strip electrode; then use the optical overlay method to grow Cr (5nm ) / Au(25nm) strip electrode; using ultra-high vacuum thermal evaporation to grow wedge-shaped organic layer Alq on the surface of LSMO and Cr / Au electrode 3 , the thickness of the wedge-shaped organic layer is 10-100nm, and the thickness of the wedge-shaped organic layer changes continuously along the direction of the LSMO strip electrode. The thinnest part is 10nm, and the thickest part is 100nm; A Co electrode with a thickness of 15nm is used, and a physical mask is used to realize the in-situ forming of the strip electrode. The direction is perpendicular to the LSMO electrode, and a NaCl protective layer is grown on the surface of the Co strip electrode.

[0044] By applying a voltage between LSMO-Cr / Au, a spin-polarized current is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com