Slowly digestible potato steamed bread rich in grape seed proanthocyanidin and making method of steamed bread

A proanthocyanidin and grape seed technology, applied in the field of food processing, can solve problems such as waste of resources, and achieve the effects of increasing production value, improving blood sugar levels, and increasing specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Mix 100 parts of flour, 65 parts of mashed potatoes, 0.8 parts of yeast, 1 part of grape seed extract, 5 parts of sucrose, 0.05 parts of salt, and 13 parts of water;

[0033] (2) Knead the dough: mix the raw and auxiliary materials and knead with a kneading machine until the surface of the dough is smooth and slightly sticky;

[0034] (3) Noodle shaping: Roll the dough with a noodle rolling machine until the dough is smooth and slightly sticky. Shape the dough and cut into 50g portions;

[0035] (4) Fermentation: The temperature and humidity of fermentation are 38°C and 85%, respectively, and the volume of steamed buns increases to 1.5 times the original, about 50 minutes;

[0036] (5) Steaming: Steam in a steamer for 23 minutes to obtain steamed buns.

Embodiment 2

[0038] (1) Mix 100 parts of flour, 65 parts of mashed potatoes, 0.8 parts of yeast, 3 parts of grape seed extract, 5 parts of sucrose, 0.05 parts of salt, and 13 parts of water;

[0039] (2) Knead the dough: mix the raw and auxiliary materials and knead with a kneading machine until the surface of the dough is smooth and slightly sticky;

[0040] (3) Noodle shaping: Roll the dough with a noodle rolling machine until the dough is smooth and slightly sticky. Shape the dough and cut into 50g portions;

[0041] (5) Fermentation: The temperature and humidity of fermentation are 38°C and 85%, respectively, and the volume of steamed buns increases to 1.5 times the original, about 50 minutes;

[0042] (6) Steaming: Steam in a steamer for 23 minutes to obtain steamed buns.

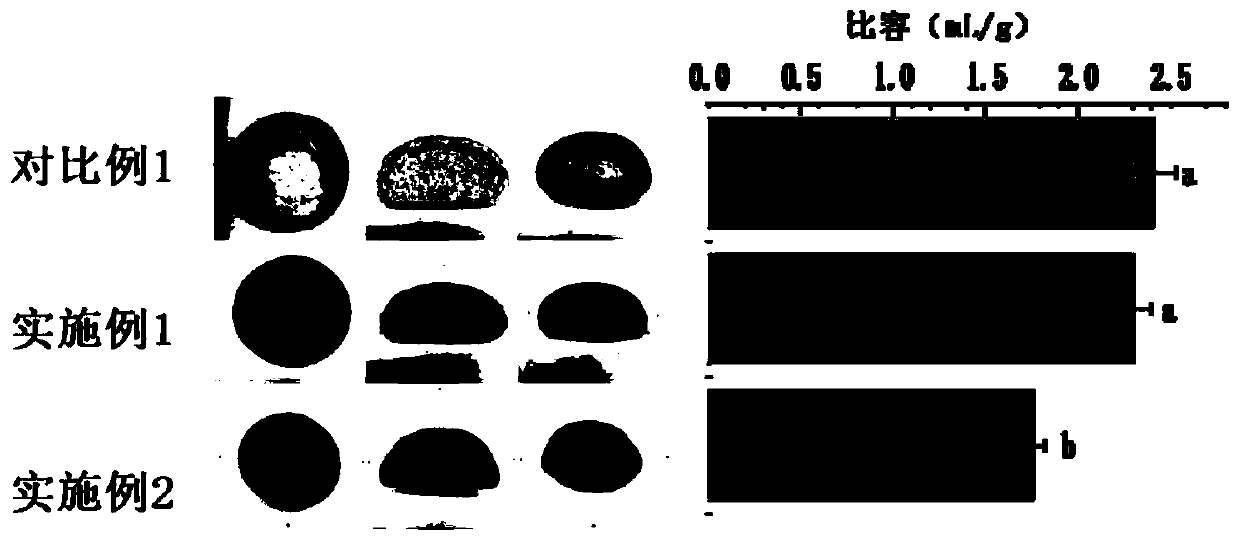

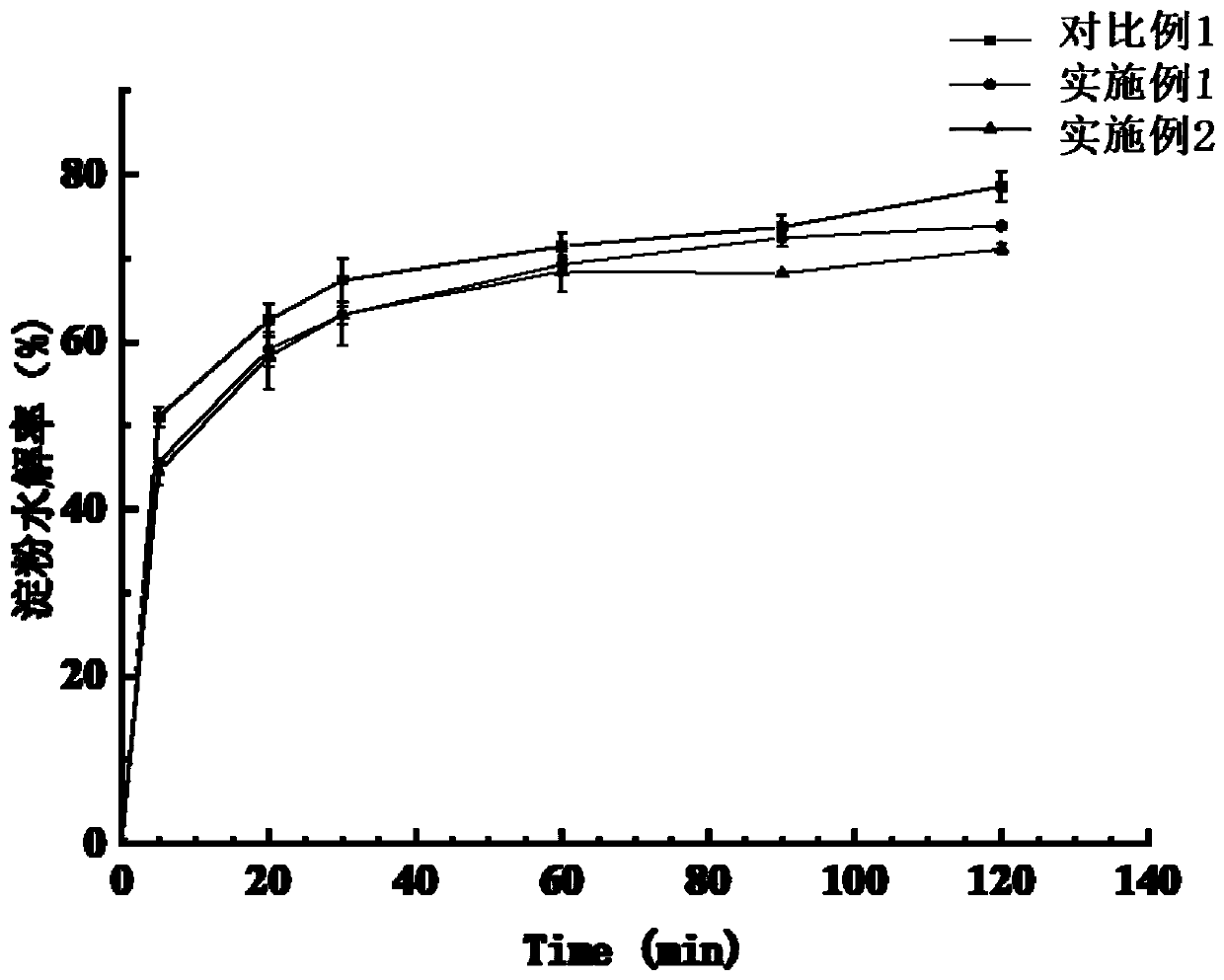

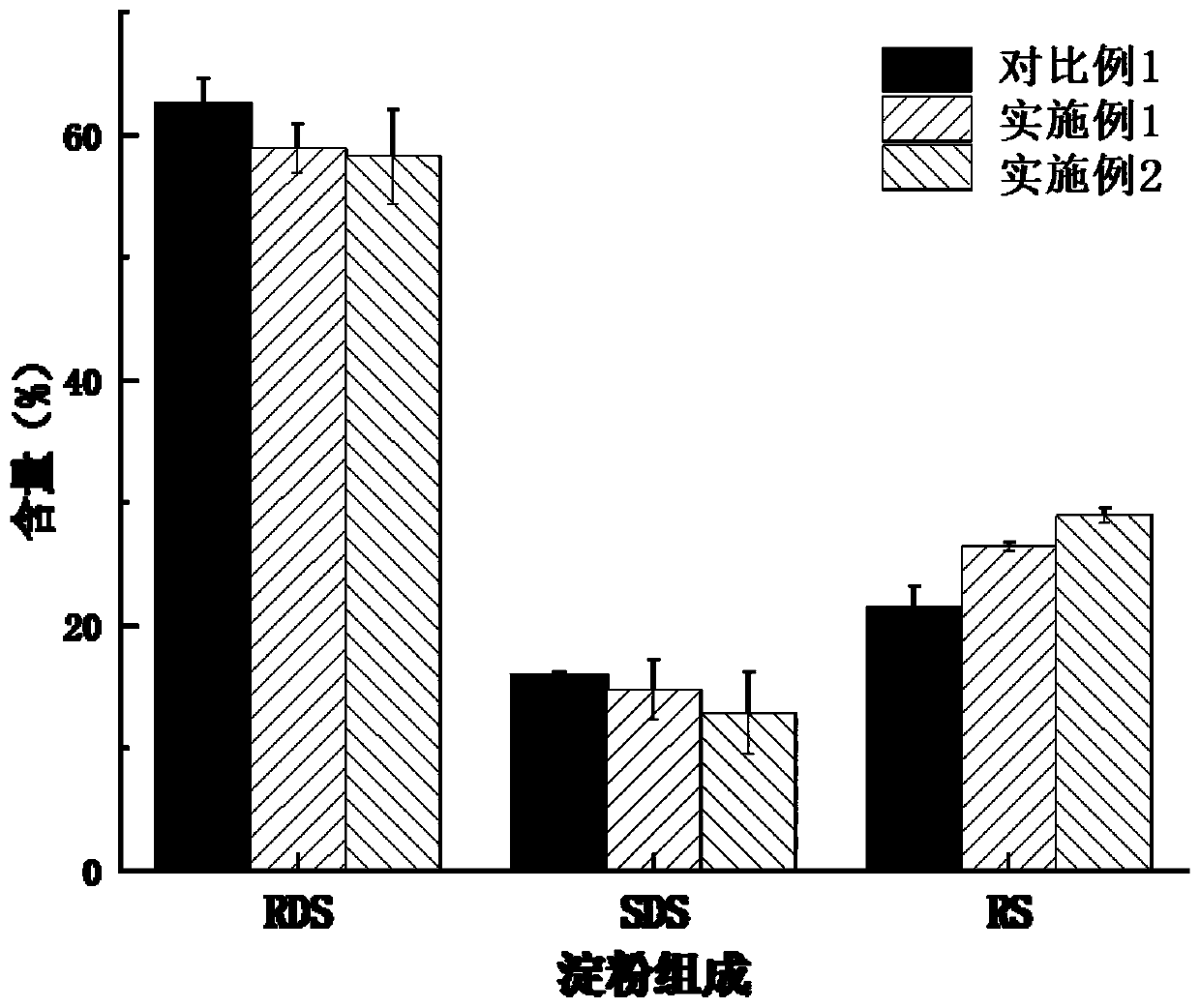

[0043] After placing the steamed buns in Comparative Example 1 and Examples 1 and 2 at room temperature for 30 minutes, weigh them immediately; use the millet replacement method to measure the volume of the steam...

Embodiment 3

[0085] (1) Mix 100 parts of flour, 60 parts of mashed potatoes, 0.5 parts of grape seed extract, 0.3 parts of yeast, 5 parts of sucrose, 0 parts of salt, and 17 parts of water;

[0086] (2) Knead the dough: mix the raw and auxiliary materials and knead with a kneading machine until the surface of the dough is smooth and slightly sticky;

[0087] (3) Noodle shaping: Roll the dough with a noodle rolling machine until the dough is smooth and slightly sticky. Shape the dough and cut into 50g portions;

[0088] (4) Fermentation: The temperature and humidity of fermentation are 38°C and 85%, respectively, and the volume of steamed buns increases to 1.5 times the original, about 50 minutes;

[0089] (5) Steaming: Steam in a steamer for 23 minutes to obtain steamed buns. Steamed bread has a lower starch digestion rate and better sensory quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com