A vane type variable diameter Venturi throat

A Venturi and blade-type technology, which is applied in the field of flue gas purification and environmental protection equipment manufacturing, can solve the problems of desulfurization tower flue gas flow rate reduction, desulfurization tower collapse bed, flue gas volume reduction, etc., to achieve reduced recirculation volume, simple equipment, The effect of easy maintenance

Active Publication Date: 2021-11-30

SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL +1

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the load change of the boiler will cause the change of flue gas flow rate, especially when the boiler is at low load, the flue gas volume will be greatly reduced, which will reduce the flow rate of the flue gas entering the desulfurization tower, which often leads to bed collapse in the desulfurization tower (in the circulating fluidized bed) A large number of solid particles fall back to the bottom of the absorption tower), and even desulfurization outages and furnace shutdowns occur

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0056] Taking the semi-dry desulfurization of a power plant as an example, when the net flue gas recirculation system is turned on from 75% load to 60% load, the power consumption rate of the plant can be reduced by 0.2-0.4% after using the device of the present invention, and the energy-saving effect is remarkable. Such as Figure 7 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

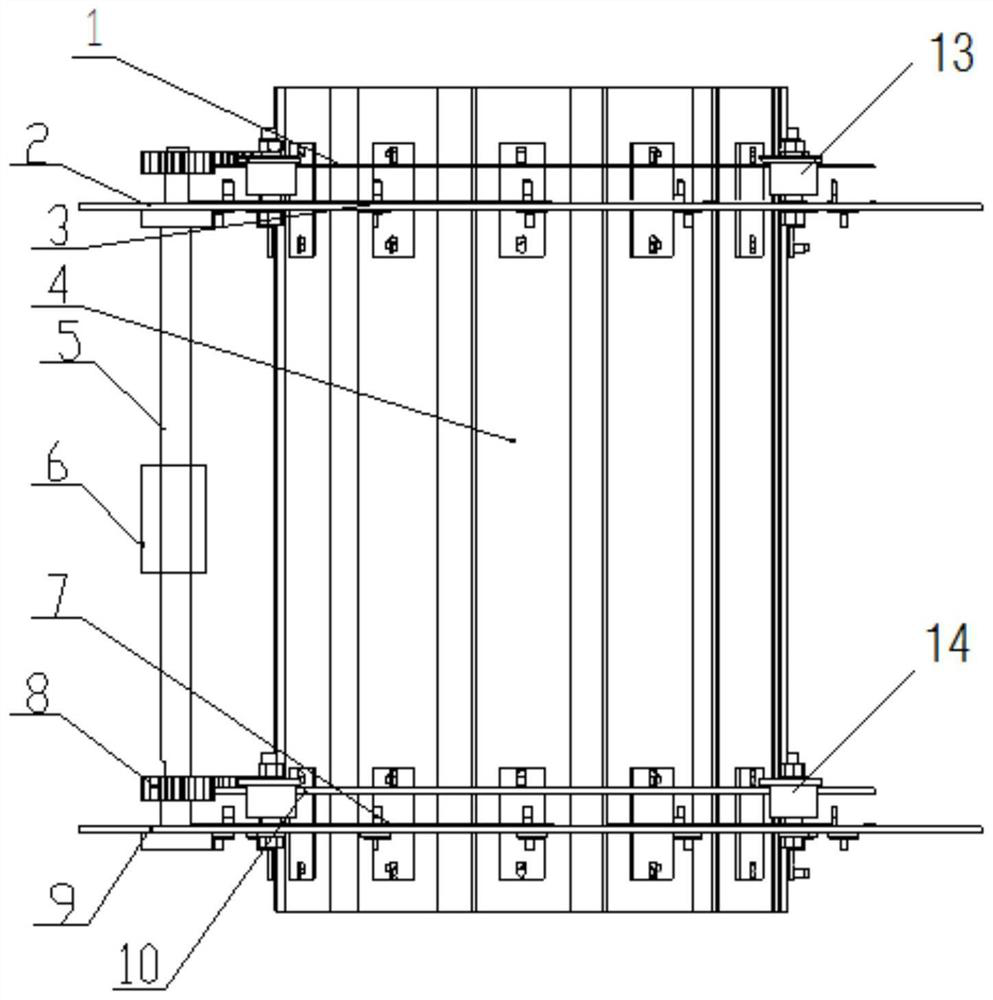

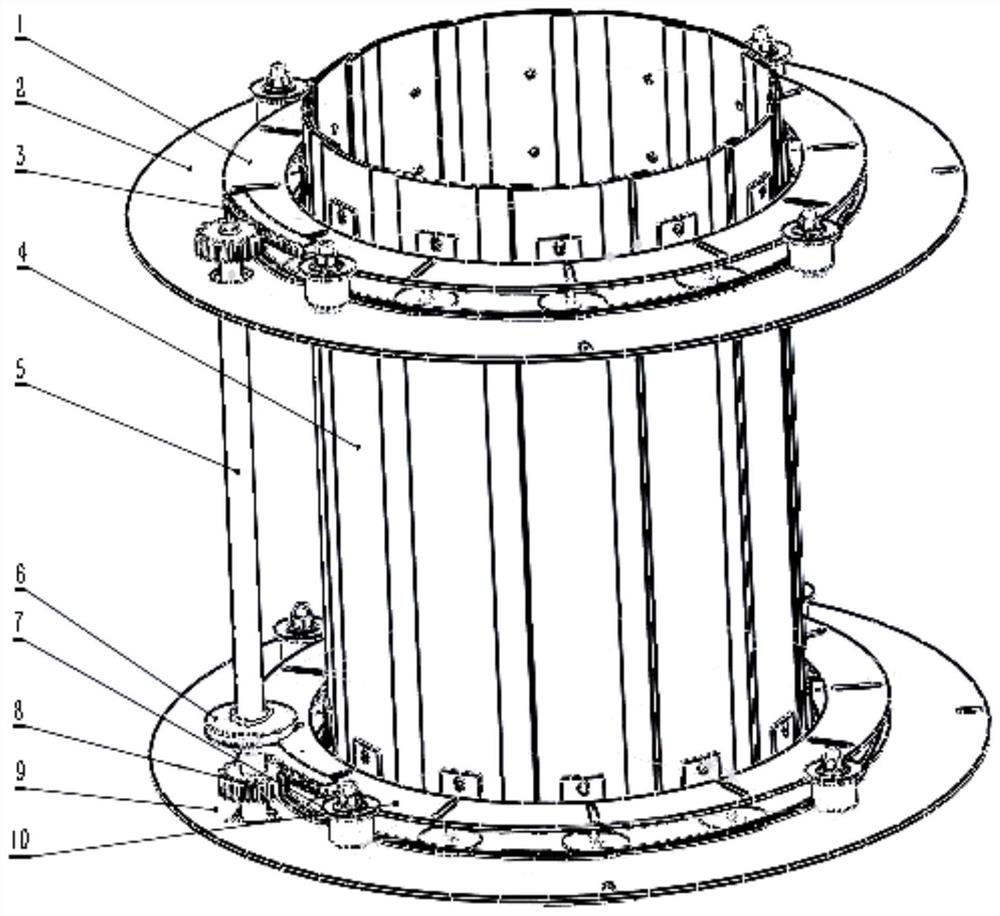

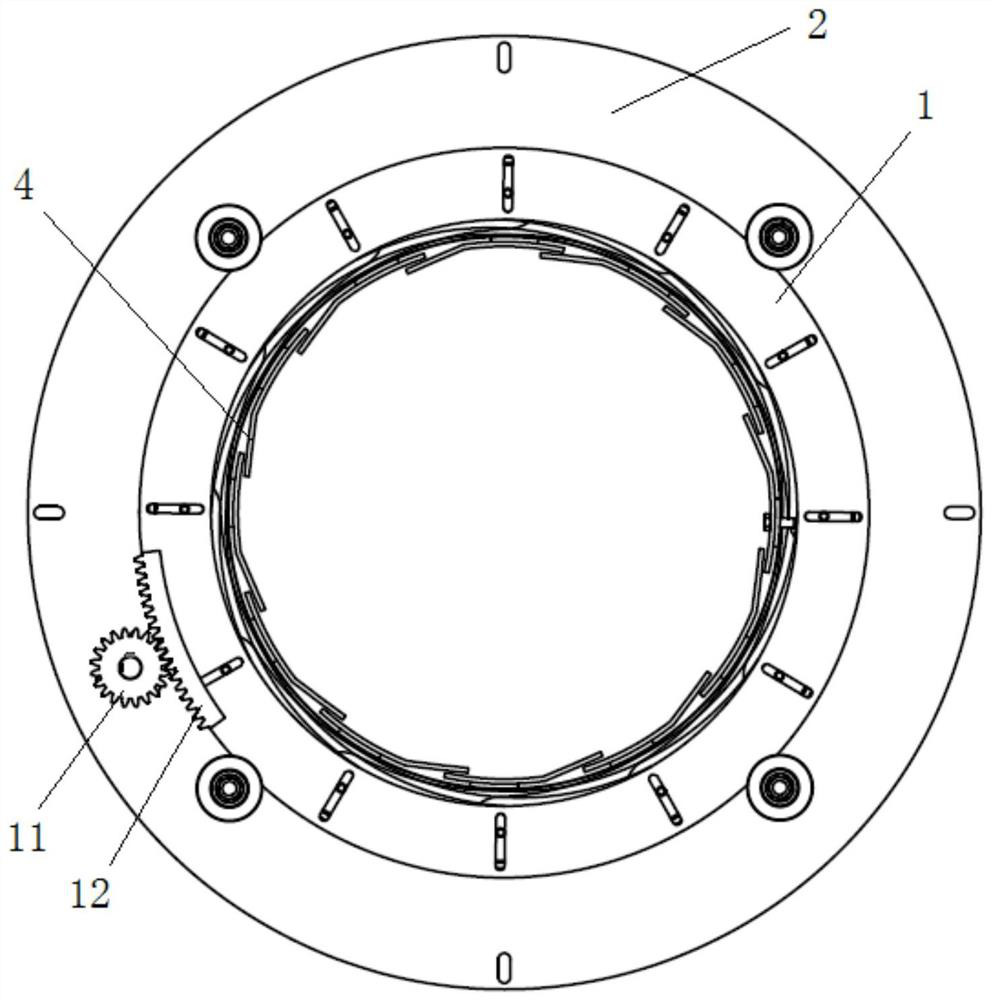

The invention discloses a vane-type variable-diameter Venturi throat structure, design principle and main performance parameters. , gears, lower fixed plate, lower moving plate, etc. Through the effective operation of each component, the automatic adjustment of the flow rate of the desulfurization flue gas is realized. The beneficial effect of the present invention is: solve the desulfurization "collapsed bed" caused by the change of flue gas volume, realize the stable, continuous and efficient operation of circulating fluidized bed flue gas desulfurization; ‑100% can be adjusted arbitrarily; the equipment is simpler and more compact, and the operation, maintenance and repair are convenient, which improves the operation rate of the equipment; the flue gas flow rate can be adjusted according to the needs, and the recirculation amount of the desulfurizer can be reduced to achieve energy saving and consumption reduction; it can be easily included The desulfurization automatic control system realizes online automatic adjustment with flue gas volume changes.

Description

technical field [0001] The invention relates to the technical field of flue gas purification and environmental protection equipment manufacturing, and relates to flue gas regulating equipment for a circulating fluidized bed desulfurization project, in particular to a blade-type variable-diameter Venturi throat. Background technique [0002] As far as the emission control of flue gas desulfurization of coal-fired boilers is concerned, circulating fluidized bed flue gas desulfurization is widely used as a relatively mature desulfurization process. Circulating fluidized bed flue gas desulfurization is a new type of semi-dry desulfurization process using circulating fluidized bed as a desulfurization absorption reactor. This process makes full use of the unique characteristics of circulating fluidized bed. The gas and reactants reach a state of intense turbulence, the absorbent circulates many times and the contact reaction time with the flue gas is long, which greatly improves ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D53/80B01D53/48

CPCB01D53/48B01D53/80B01D2258/0283

Inventor 李忠仁吴华武锡平李斌

Owner SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com