Moso bamboo tube efficient bamboo outer skin removing device based on water jet flows

A water jet technology to remove bamboo green, applied in abrasive feeding device, used abrasive processing device, abrasive jet machine tool, etc. Application requirements and other issues to achieve the effect of reducing roughness, improving processing efficiency, and meeting the needs of green manufacturing and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

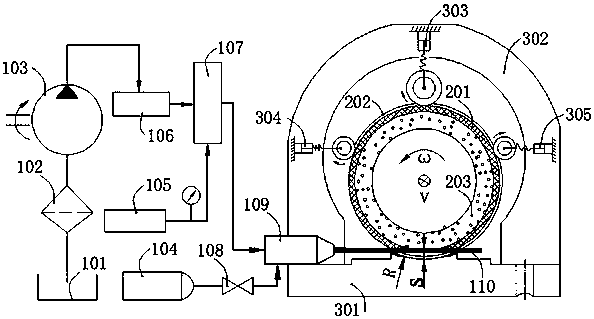

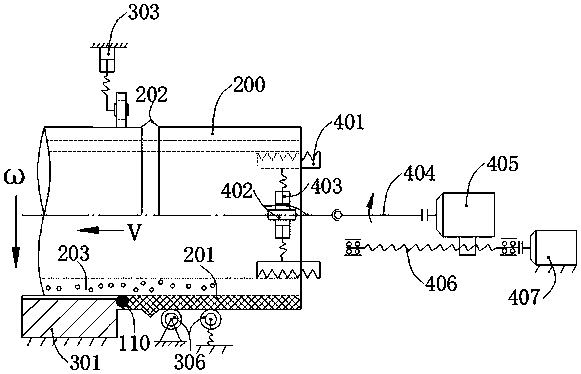

[0029] Such as Figure 1-3 Shown is a water jet-based high-efficiency bamboo removal device for bamboo tubes. The device includes a water jet generation unit, a positioning support unit, and a clamping and rotating propulsion unit.

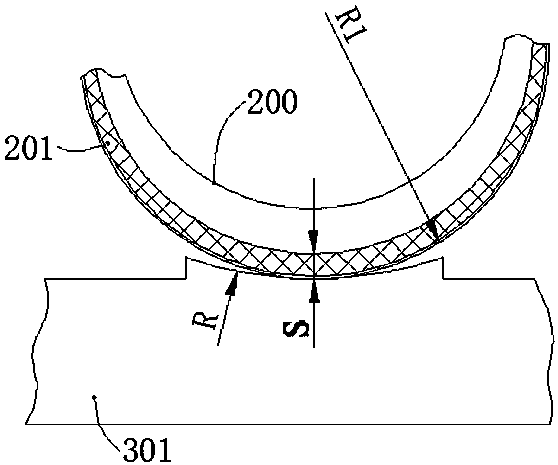

[0030] The water jet generation unit is used to form the water jet 110 that cuts the green bamboo 201, and the injection direction of the water jet 110 is tangent to the inner wall side of the green bamboo 201 and is close to the cylindrical surface of the outer wall side of the bamboo meat 203; the water jet generation unit includes a water tank 101 , filter mechanism 102, water pump 103, sand tank 104, supercharger 105, energy storage tank 106, water jet controller 107, abrasive valve 108, nozzle 109, the water in the water tank 101 is filtered by filter mechanism 102, pumped by water pump 103 Suction, through the energy storage tank 106 to achieve stable pressure, through the supercharger 105 to achieve pressurization and supply to the nozzle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com