Preparation method of coffee ground substrate active carbon

A technology for the preparation of activated carbon and coffee grounds, applied in chemical instruments and methods, inorganic chemistry, water/sludge/sewage treatment, etc., can solve problems such as low effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

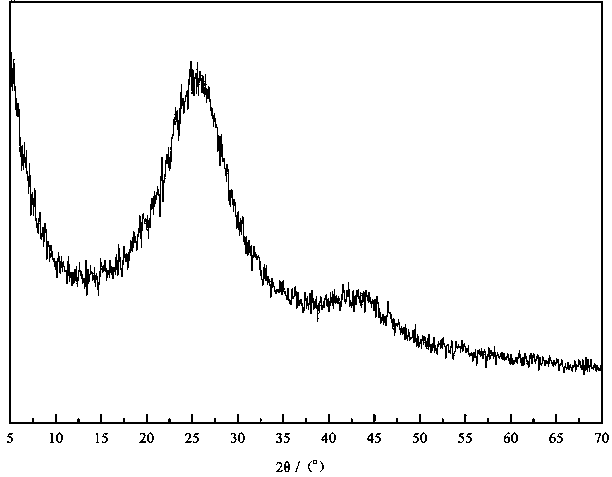

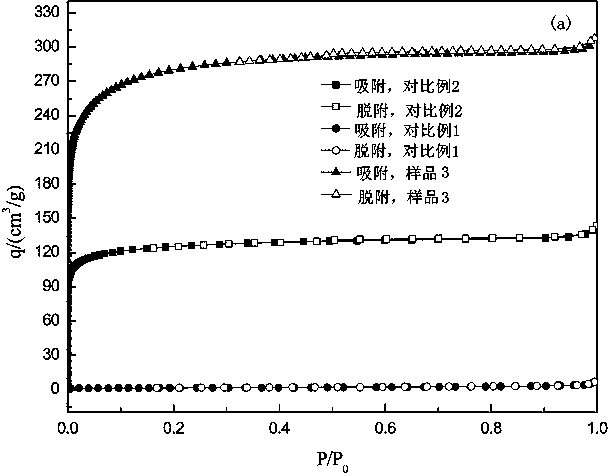

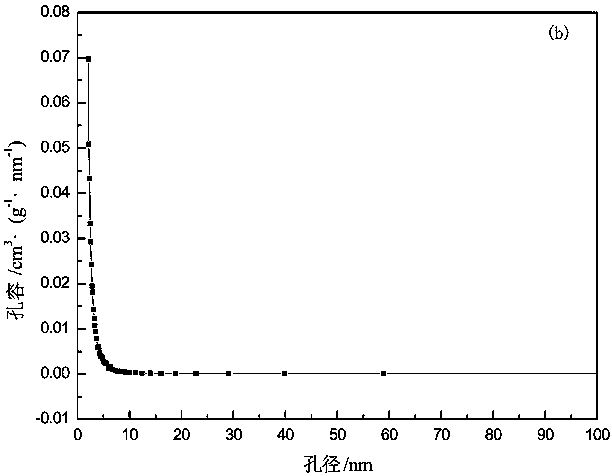

[0023] Embodiment 1 coffee grounds matrix activated carbon preparation method 1

[0024] (a) Soak the coffee grounds in distilled water several times, dry them at 100°C, pass through an 80-mesh sieve for later use, and obtain dry coffee grounds;

[0025] (b) Put the dry coffee grounds into the container, add a phosphoric acid solution with a mass percentage concentration of 8%, and the volume of the phosphoric acid solution is 4 mL·g based on the mass of the dry coffee grounds -1 , after stirring, ultrasonically oscillate it in an ultrasonic cleaner for 3 hours, filter and wash the coffee grounds until neutral, and dry them at 100°C to obtain acid-treated coffee grounds;

[0026] (c) Put the acid-treated coffee grounds into a muffle furnace for activation, and control the heating rate at 8 °C min -1 , gradually raised the temperature to 580°C, kept it warm for 2 hours, cooled it down to room temperature naturally, took it out, washed it with distilled water until it was neutr...

Embodiment 2

[0027] Embodiment 2 coffee grounds matrix activated carbon preparation method 1

[0028] (a) Soak the coffee grounds in distilled water several times, dry them at 110°C, pass through a 100-mesh sieve for later use, and obtain dry coffee grounds;

[0029] (b) Put the dry coffee grounds into the container, add a phosphoric acid solution with a mass percentage concentration of 12%, and the volume of the phosphoric acid solution is 6 mL·g based on the mass of the dry coffee grounds -1 , after stirring, ultrasonically oscillate it in an ultrasonic cleaner for 4 hours, filter and wash the coffee grounds until neutral, and dry them at 100°C to obtain acid-treated coffee grounds;

[0030] (c) Put the acid-treated coffee grounds into a muffle furnace for activation, and control the heating rate at 12 °C min -1 , gradually raised the temperature to 620°C, kept warm for 1, cooled naturally to room temperature, took out, washed with distilled water until neutral, dried and sieved to obta...

Embodiment 3

[0031] Embodiment 3 coffee grounds matrix activated carbon preparation method

[0032] (a) Soak coffee grounds in distilled water several times, dry at 105°C, pass through a 90-mesh sieve for later use, and obtain dry coffee grounds;

[0033] (b) Put the dry coffee grounds into the container, add a phosphoric acid solution with a mass percentage concentration of 10%, and the volume of the phosphoric acid solution is 5 mL·g based on the mass of the dry coffee grounds -1 , after stirring, ultrasonically oscillate it in an ultrasonic cleaner for 3.5 hours, filter and wash the coffee grounds until neutral, and dry them at 105°C to obtain acid-treated coffee grounds;

[0034] (c) Put the acid-treated coffee grounds into a muffle furnace for activation, and control the heating rate at 10 °C min -1 , gradually raised the temperature to 600°C, kept it warm for 1.5h, cooled it down to room temperature naturally, took it out, washed it with distilled water until it was neutral, dried i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption total pore volume | aaaaa | aaaaa |

| Adsorption total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com