Columnar mullite brick with high wear resistance, and production method thereof

A mullite, high wear-resistant technology, applied in the field of refractory materials, can solve the problems of poor wear resistance, poor volume stability, low cost performance, etc., to achieve the effect of low price, guaranteed volume stability, and improved cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

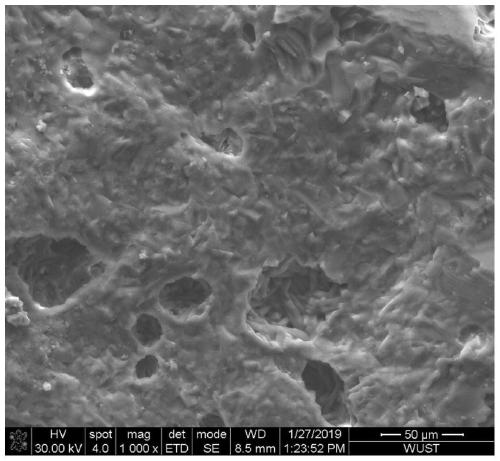

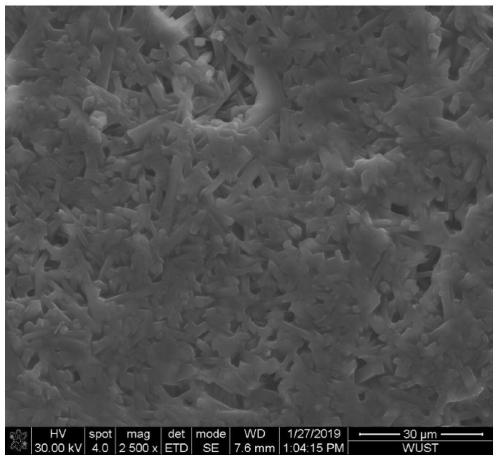

Image

Examples

Embodiment 1

[0035] A columnar mullite high wear-resistant brick and its preparation method:

[0036] (1) The preparation method of described bauxite granulation material is: earlier with secondary bauxite clinker particle, secondary bauxite raw meal powder, chromite powder, yttrium oxide powder and silica sol by mass ratio 65:35: 6:8:20 Ingredients, mixed evenly and pressed into a green body under a pressure of 30-50MPa; then put the green body at 100-140°C for 24 hours; finally, crush the dried green body into granules smaller than 5mm , that is, bauxite pellets.

[0037] (2) The composition and mass ratio of the columnar mullite high wear-resistant brick are:

[0038]

[0039] (3) According to the above-mentioned raw materials and their contents, the three-grade bauxite raw meal powder, pyrophyllite fine powder, SiO 2 Micropowder, α-Al 2 o 3 Micropowder, CeO 2 Blend the micropowder, Al-Zn alloy powder and potassium carbonate, and the mixing time is 3 to 5 minutes to make the mix...

Embodiment 2

[0042] A columnar mullite high wear-resistant brick and its preparation method:

[0043] (1) The preparation method of described bauxite granulation material is: earlier with secondary bauxite clinker particle, secondary bauxite raw meal powder, chromite powder, yttrium oxide powder and silica sol by mass ratio 65:35: 4:2:10 ingredients, mixed evenly and pressed into a green body under a pressure of 30-50MPa; then put the green body at 100-140°C for 24 hours; finally, crush the dried green body into granules smaller than 5mm , that is, bauxite pellets.

[0044] (2) The composition and mass ratio of the columnar mullite high wear-resistant brick are:

[0045]

[0046] (3) According to the above-mentioned raw materials and their contents, the three-grade bauxite raw meal powder, pyrophyllite fine powder, SiO 2 Micropowder, α-Al 2 o 3 Micropowder, CeO 2 Blend the micropowder, Al-Zn alloy powder and potassium carbonate, and the mixing time is 3 to 5 minutes to make the mix...

Embodiment 3

[0049] A columnar mullite high wear-resistant brick and its preparation method:

[0050] (1) The preparation method of described bauxite granulation material is: earlier with secondary bauxite clinker particle, secondary bauxite raw meal powder, chromite powder, yttrium oxide powder and silica sol by mass ratio 65:35: (4~5):(2~4):(10~16) Ingredients, mixed evenly and pressed into green body under 30-50MPa pressure; then put the green body at 100-140°C for 24 hours; finally dry The final green body is broken into granules smaller than 5 mm to obtain bauxite granules.

[0051] (2) The composition and mass ratio of the columnar mullite high wear-resistant brick are:

[0052]

[0053] (3) According to the above-mentioned raw materials and their contents, the three-grade bauxite raw meal powder, pyrophyllite fine powder, SiO 2 Micropowder, α-Al 2 o 3 Micropowder, CeO 2 Blend the micropowder, Al-Zn alloy powder and potassium carbonate, and the mixing time is 3 to 5 minutes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com