Solventless thermal-insulation anticorrosive coating and anticorrosive coating layer

An anti-corrosion coating and solvent-free technology, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve problems such as insufficient thermal insulation and anti-corrosion effects, and achieve the effects of improving construction efficiency, preventing heat loss, and improving thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 10

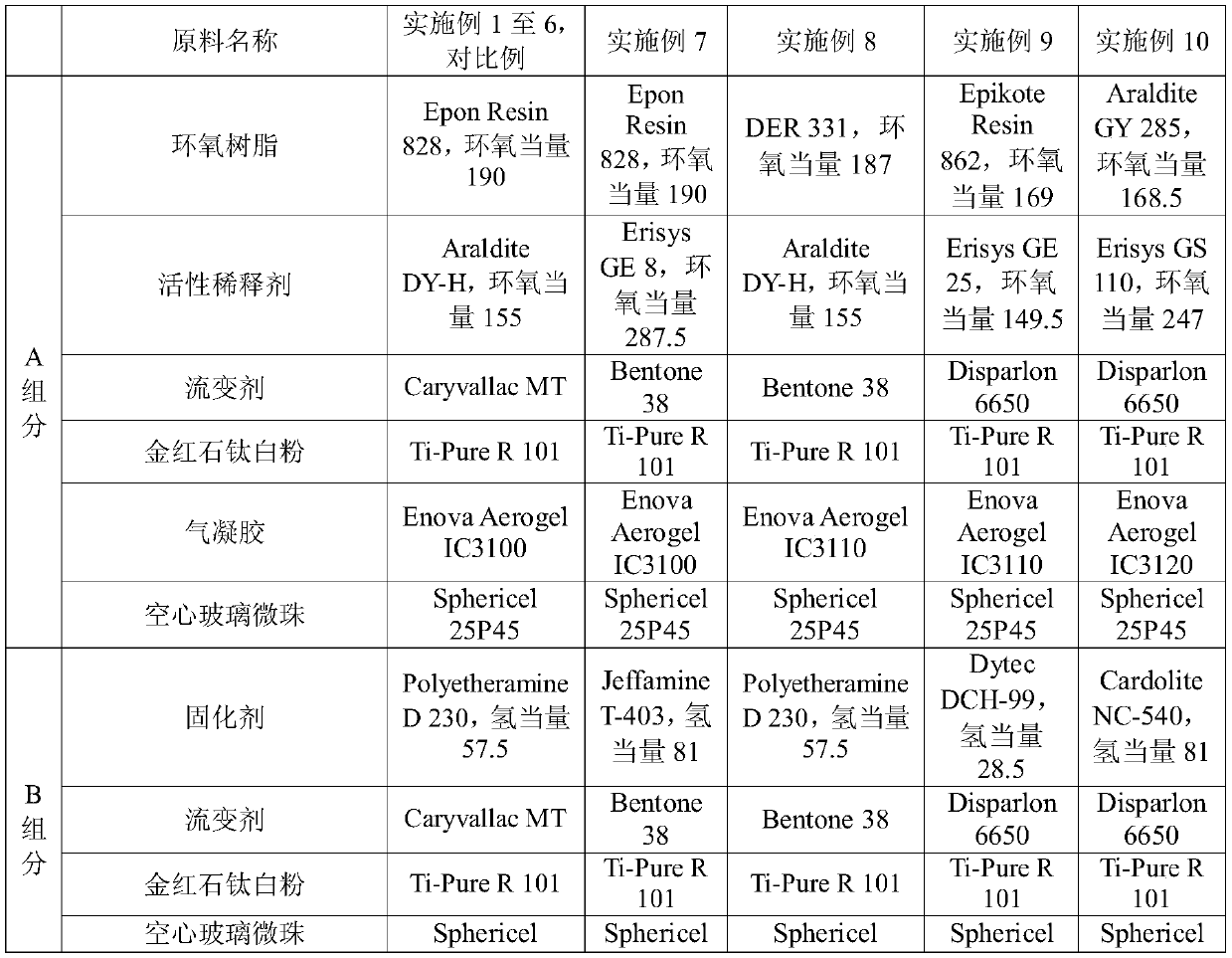

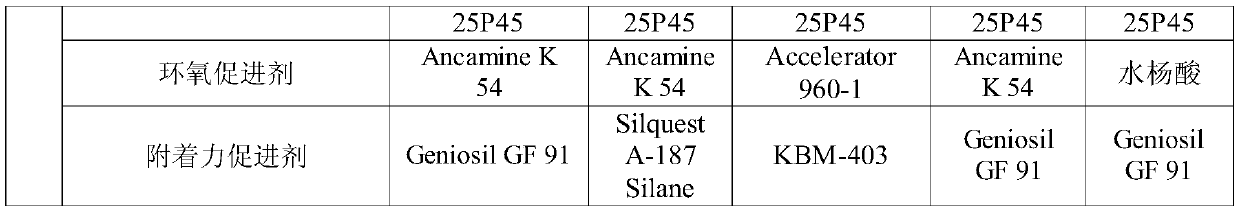

[0064] The solvent-free heat-insulating and anti-corrosion paint in the embodiment 1 to 10 of the present invention is realized by the following production process:

[0065] Component A: Use a high-speed disperser to mix the epoxy resin and the active diluent evenly. During the mixing process, add rheology agent, rutile titanium dioxide and airgel, and disperse at high speed to a maximum fineness of 60 microns; then add hollow glass microspheres, Stir well.

[0066] Component B: Add curing agent to the high-speed disperser, add rheology agent and rutile titanium dioxide during stirring, disperse at high speed to a maximum fineness of 60 microns, then add hollow glass microspheres, stir evenly, then add epoxy accelerator and Adhesion promoter, stir well.

[0067] Before use, component A and component B were mixed according to the weight ratio shown in Table 1 to prepare solvent-free heat-insulating and anti-corrosion coatings in various embodiments of the present invention.

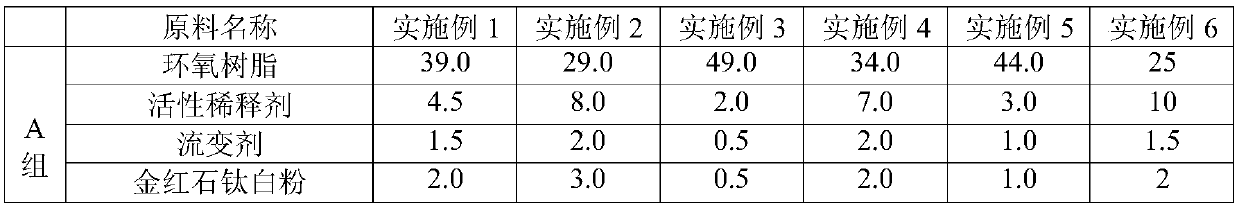

Embodiment 1

[0068] The composition of the solvent-free thermal insulation and anticorrosion coatings provided in Examples 1 to 6 is shown in Table 2. If there is no corresponding component in Table 2, the component will not be added during the production process. The weight composition of Examples 7 to 10 is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com