Corrosion-resistant electric cabinet for wind power generation and preparation method ofcorrosion-resistant electric cabinet

An electric control box, corrosion-resistant technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problem of only meeting the corrosion resistance requirements but not meeting the corrosion resistance requirements, etc., to improve the heat aging performance and improve the heat insulation. effect, the effect of improving insulation and antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

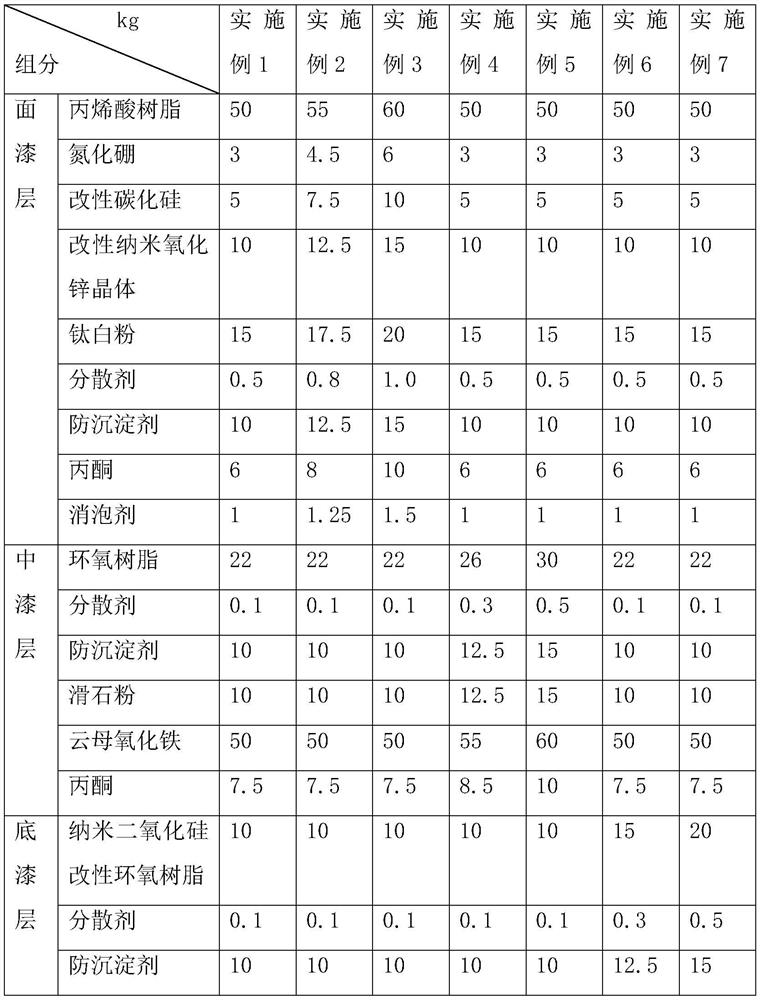

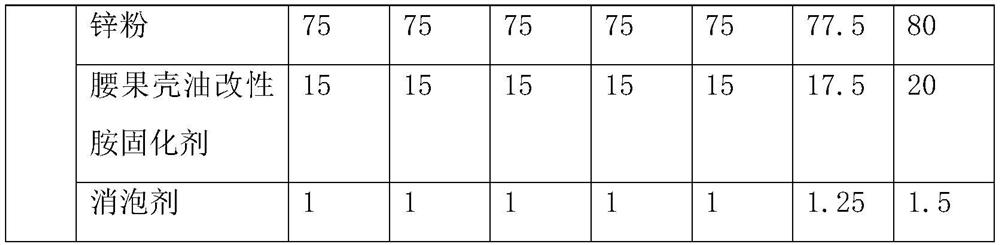

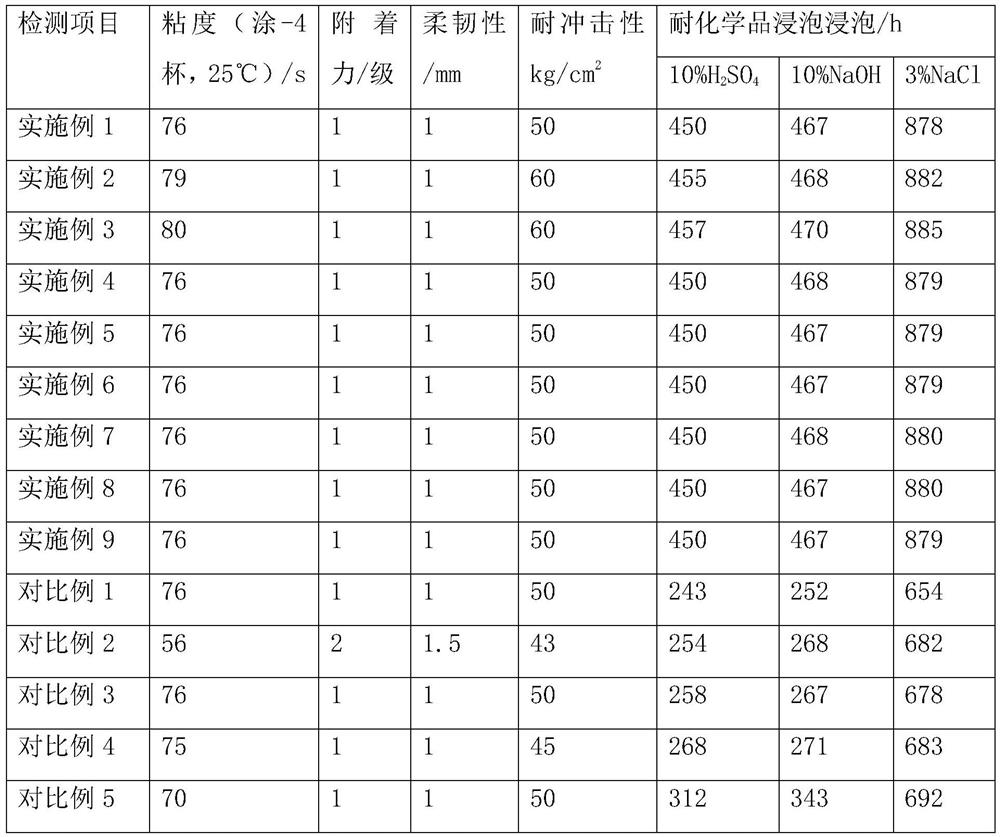

Examples

preparation example 1-3

[0042] In Preparation Example 1-3, the titanate coupling agent KH201 was selected from the titanate coupling agent KH201 sold by Dongguan Shanyi Plastic Chemical Co., Ltd. with the product number of 201, and the nano-zinc oxide was selected from Ningbo Bekal New Material Co., Ltd. The sold article number is the nano-zinc oxide of Beigaer-ZnO-1, and the ammonium citrate is selected from the ammonium citrate whose article number is 5623 sold by Suzhou Rongguang Chemical Co., Ltd.

preparation example 1

[0043] Preparation Example 1: Mix 0.3kg of titanate coupling agent KH201 and 3kg of acetone, add 4kg of isopropanol and 1kg of nano-zinc oxide, stir evenly, filter with suction, wash with acetone, and dry in an incubator at 80°C to obtain Pretreatment nano-zinc oxide, the particle size of nano-zinc oxide is 20nm;

[0044] (2) Mix copper oxide and pretreated nano-zinc oxide, add ammonium citrate with a concentration of 60%, grind for 2.5 hours at a rotating speed of 2500r / min, take it out, and ultrasonically 30min to prepare modified nano-zinc oxide crystals, oxidize The mass ratio of copper, pretreated nano zinc oxide and ammonium citrate is 1:1:1.6.

preparation example 2

[0045] Preparation Example 2: Mix 0.4kg of titanate coupling agent KH201 and 4kg of acetone, add 6kg of isopropanol and 1.5kg of nano-zinc oxide, stir evenly, filter with suction, wash with acetone, dry in an incubator at 85°C, and prepare Obtain pretreatment nano-zinc oxide, the particle diameter of nano-zinc oxide is 20nm;

[0046] (2) Mix copper oxide and pretreated nano-zinc oxide, add ammonium citrate with a concentration of 63%, grind for 2 hours at a speed of 3000r / min, take it out, and ultrasonically 35min to prepare modified nano-zinc oxide crystals, copper oxide , The mass ratio of the pretreated nanometer zinc oxide and ammonium citrate is 1:1.5:2.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com