Method for efficiently recovering copper from low-grade secondary copper sulfide ore

A copper sulfide ore, low-grade technology, applied in the improvement of process efficiency, instruments, optics, etc., can solve the problems of inability to achieve high efficiency, economic recovery, little effect of grinding costs, limited ore processing capacity, etc. Avoid difficult and orderly collection, significant ecological benefits, and good environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

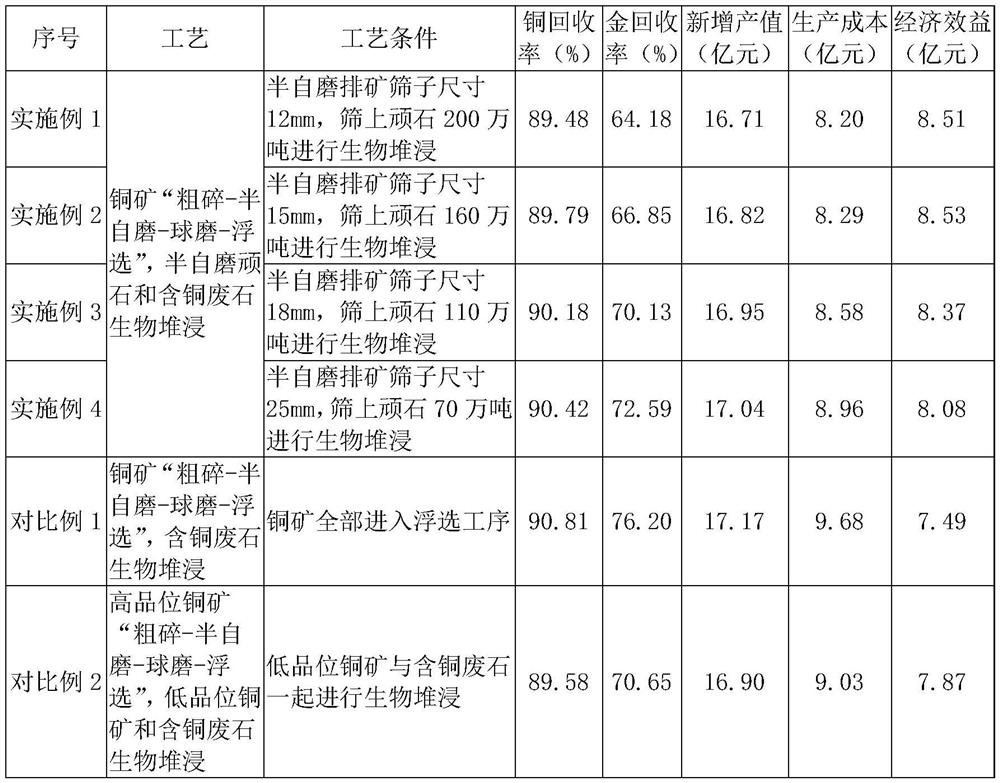

Embodiment 1

[0033] A secondary copper sulfide mine mines 8 million tons of ore each year (average copper grade 0.40%, gold grade 0.11g / t), and produces 2 million tons of copper-bearing waste rock (average copper grade 0.13%, gold grade 0.05g / t) ). The copper ore is firstly crushed, semi-autogenously ground, and the semi-autogenously ground ore is screened with a 12mm sieve to obtain 6 million tons of -12mm copper ore (average copper grade 0.48%, gold grade 0.123g / t) and 2 million tons of stubborn stone (average copper grade 0.16%, gold grade 0.07g / t). The -12mm copper ore was ball milled and treated by flotation to obtain 119,000 tons of copper concentrate (average copper grade 22.50%, gold grade 5.28g / t). The stubborn rock and copper-containing waste rock were mixed and then bioheap leached, and the leachate was treated by the "extraction-electrodeposition" process to obtain 4,176 tons of cathode copper. The comprehensive recovery rate of copper is 89.48%, and the comprehensive recover...

Embodiment 2

[0035] A secondary copper sulfide mine mines 8 million tons of ore each year (average copper grade 0.40%, gold grade 0.11g / t), and produces 2 million tons of copper-bearing waste rock (average copper grade 0.13%, gold grade 0.05g / t) ). The copper ore is firstly crushed and semi-autogenously ground, and the semi-autogenously ground ore is screened with a 15mm sieve to obtain 6.4 million tons of -15mm copper ore (average copper grade 0.46%, gold grade 0.121g / t) and 1.6 million tons of stubborn stone (average copper grade 0.15%, gold grade 0.068g / t). The -15mm copper ore was ball milled and treated by flotation to obtain 124,400 tons of copper concentrate (average copper grade 22.10%, gold grade 5.27g / t). The stubborn rock and copper-containing waste rock were mixed and then bioheap leached. The leachate was treated by the "extraction-electrodeposition" process to obtain 3575.50 tons of cathode copper. The comprehensive recovery rate of copper is 89.79%, and the comprehensive r...

Embodiment 3

[0037] A secondary copper sulfide mine mines 8 million tons of ore each year (average copper grade 0.40%, gold grade 0.11g / t), and produces 2 million tons of copper-bearing waste rock (average copper grade 0.13%, gold grade 0.05g / t) ). The copper ore is firstly crushed and semi-autogenously ground, and the semi-autogenously ground ore is screened with a sieve with a size of 18mm to obtain 6.9 million tons of -18mm copper ore (average copper grade 0.44%, gold grade 0.117g / t) and 1.1 million tons of stubborn stone (average copper grade 0.14%, gold grade 0.065g / t). The -18mm copper ore was ball milled and treated by flotation to obtain 129,600 tons of copper concentrate (average copper grade 21.80%, gold grade 5.30g / t). The obstinate rock and copper-containing waste rock were mixed and then bioheap leached, and the leachate was treated by the "extraction-electrodeposition" process to obtain 2,948.09 tons of cathode copper. The comprehensive recovery rate of copper is 90.18%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com