A method of improving the force magnetic property of alcocrcufeni high entropy alloy by using magnetic field

A high-entropy alloy and magnetic property technology, applied in the field of high-entropy alloys, can solve the problems of increasing strength and plasticity at the same time, and reducing the yield strength of AlCoCrCuFeNi high-entropy alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

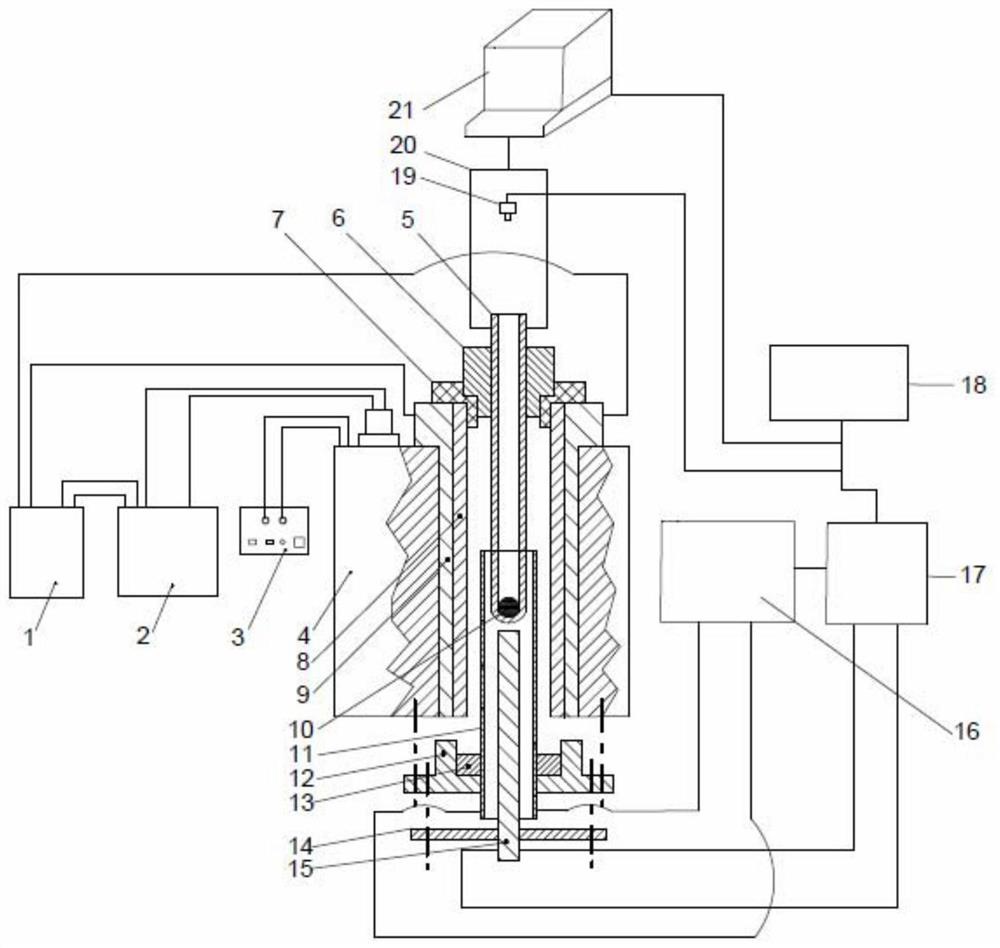

[0045] This embodiment is a method for improving the mechanical and magnetic properties of an AlCoCrCuFeNi high-entropy alloy by using a magnetic field.

[0046] The strength of the magnetic field is 2T.

[0047] The concrete steps of this embodiment are as follows:

[0048] Step 1. Alloy preparation: For ingredients, select Al, Co, Cr, Cu, Fe and Ni with a purity of not less than 99.9%; the Al, Co, Cr, Cu, Fe and Ni are solid pure raw materials. Said Al:Co:Cr:Cu:Fe:Ni=1:1:1:1:1:1 ingredients. This ratio is an atomic ratio.

[0049] Use mechanical methods to grind and remove the scale of each raw material, clean it with alcohol, put it into the crucible of the vacuum non-consumable electric arc furnace, use the vacuum non-consumable arc melting method, close the furnace door, and evacuate to 1×10 -3 Pa and then recoil high-purity argon to 0.04 ~ 0.06MPa. After arcing, the titanium ingot is melted to absorb residual oxygen in the furnace. The Al, Co, Cr, Cu, Fe and Ni are ...

Embodiment 2

[0057] This embodiment is a method for improving the mechanical and magnetic properties of an AlCoCrCuFeNi high-entropy alloy by using a magnetic field.

[0058] The magnetic field strength is 4T.

[0059] The concrete steps of this embodiment are as follows:

[0060] Step 1. Alloy preparation: For ingredients, select Al, Co, Cr, Cu, Fe and Ni with a purity of not less than 99.9%; the Al, Co, Cr, Cu, Fe and Ni are solid pure raw materials. Said Al:Co:Cr:Cu:Fe:Ni=1:1:1:1:1:1 ingredients. The stated ratios are atomic ratios.

[0061] Use mechanical methods to grind and remove the scale of each raw material, clean it with alcohol, put it into the crucible of the vacuum non-consumable electric arc furnace, use the vacuum non-consumable arc melting method, close the furnace door, and evacuate to 1×10 -3 Pa and then recoil high-purity argon to 0.04-0.06MPa; after arcing, first melt the titanium ingot to absorb the residual oxygen in the furnace, then melt each pure metal, and tur...

Embodiment 3

[0068] This embodiment is a method for improving the mechanical and magnetic properties of an AlCoCrCuFeNi high-entropy alloy by using a magnetic field.

[0069] The magnetic field strength is 10T.

[0070] The concrete steps of this embodiment are as follows:

[0071] Step 1. Alloy preparation: For ingredients, select Al, Co, Cr, Cu, Fe and Ni with a purity of not less than 99.9%; the Al, Co, Cr, Cu, Fe and Ni are solid pure raw materials. Said Al:Co:Cr:Cu:Fe:Ni=1:1:1:1:1:1 ingredients. The stated ratios are atomic ratios.

[0072]Use mechanical methods to grind and remove the scale of each raw material, clean it with alcohol, put it into the crucible of the vacuum non-consumable electric arc furnace, use the vacuum non-consumable arc melting method, close the furnace door, and evacuate to 1×10 -3 Pa and then recoil high-purity argon to 0.04-0.06MPa; after arcing, first melt the titanium ingot to absorb the residual oxygen in the furnace, then melt each pure metal, and tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com