Packaging film, preparation method thereof, and photoelectric device

A technology for encapsulating films and composite films, which is applied in the field of device encapsulation, can solve problems such as poor bending resistance and water-oxygen barrier properties, and achieve the effects of improving water-oxygen barrier properties, reducing holes, and enhancing bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

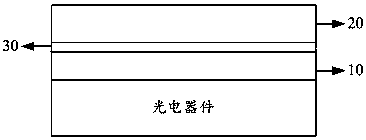

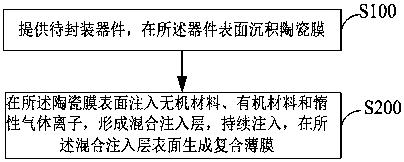

[0044] 1. The preparation method of encapsulation film comprises steps:

[0045] 1) On the top surface of the silver electrode of the photoelectric device, the aluminum nitride target is sputtered into a film by radio frequency sputtering, and the thickness of the aluminum nitride film is 50nm;

[0046] 2) Using the combination of inert gas ion implantation and sputtering, in the vacuum chamber, the vacuum degree is less than 10 -4 T, synchronously and uniformly implanting organic material PI, inorganic material silicon nitride and high-energy argon ions into the surface layer of the aluminum nitride film to form a mixed injection layer in the surface layer of the aluminum nitride film;

[0047] 3) When the mixed injection layer is sufficiently tight, a composite film is formed on the surface of the aluminum nitride film, and the thickness of the composite film is 150 nm.

Embodiment 2

[0049] 1. The preparation method of encapsulation film comprises steps:

[0050] 1) Evaporate silicon oxide to form a film on the top surface of the silver electrode of the photoelectric device by evaporation, and the thickness of the silicon oxide film is 100nm;

[0051] 2) Using the combination of inert gas ion implantation and sputtering, in the vacuum chamber, the vacuum degree is less than 10 -4 T, synchronously and uniformly implanting organic material PET, inorganic material silicon oxide, and high-energy argon ions into the surface layer of the silicon oxide film to form a mixed injection layer in the surface layer of the silicon oxide film;

[0052] 3) When the mixed injection layer is sufficiently tight, a composite film is formed on the surface of the silicon oxide film, and the thickness of the composite film is 200 nm.

Embodiment 3

[0054] 1. The preparation method of encapsulation film comprises steps:

[0055] 1) On the top surface of the silver electrode of the photoelectric device, silicon nitride is deposited into a film by ALD atomic deposition method, and the thickness of the silicon nitride film is 150nm;

[0056] 2) Using the combination of inert gas ion implantation and sputtering, in the vacuum chamber, the vacuum degree is less than 10 -4 T, synchronously and uniformly implanting organic material acrylic acid, inorganic material silicon nitride and high-energy argon ions into the surface layer of the silicon nitride film to form a mixed injection layer in the surface layer of the silicon nitride film;

[0057] 3) When the mixed injection layer is sufficiently dense, a composite film is formed on the surface of the silicon nitride film, and the thickness of the composite film is 300 nm.

[0058] In summary, the present invention provides packaging films, including laminated ceramic films and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com