High-efficiency cotton straw forage crusher

A forage pulverizer, cotton straw technology, applied in the direction of feed, agricultural machinery and implements, food science, etc., can solve the problems of clogging of the feed inlet and affecting the crushing effect, and achieve the effects of avoiding clogging, strong practicability, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

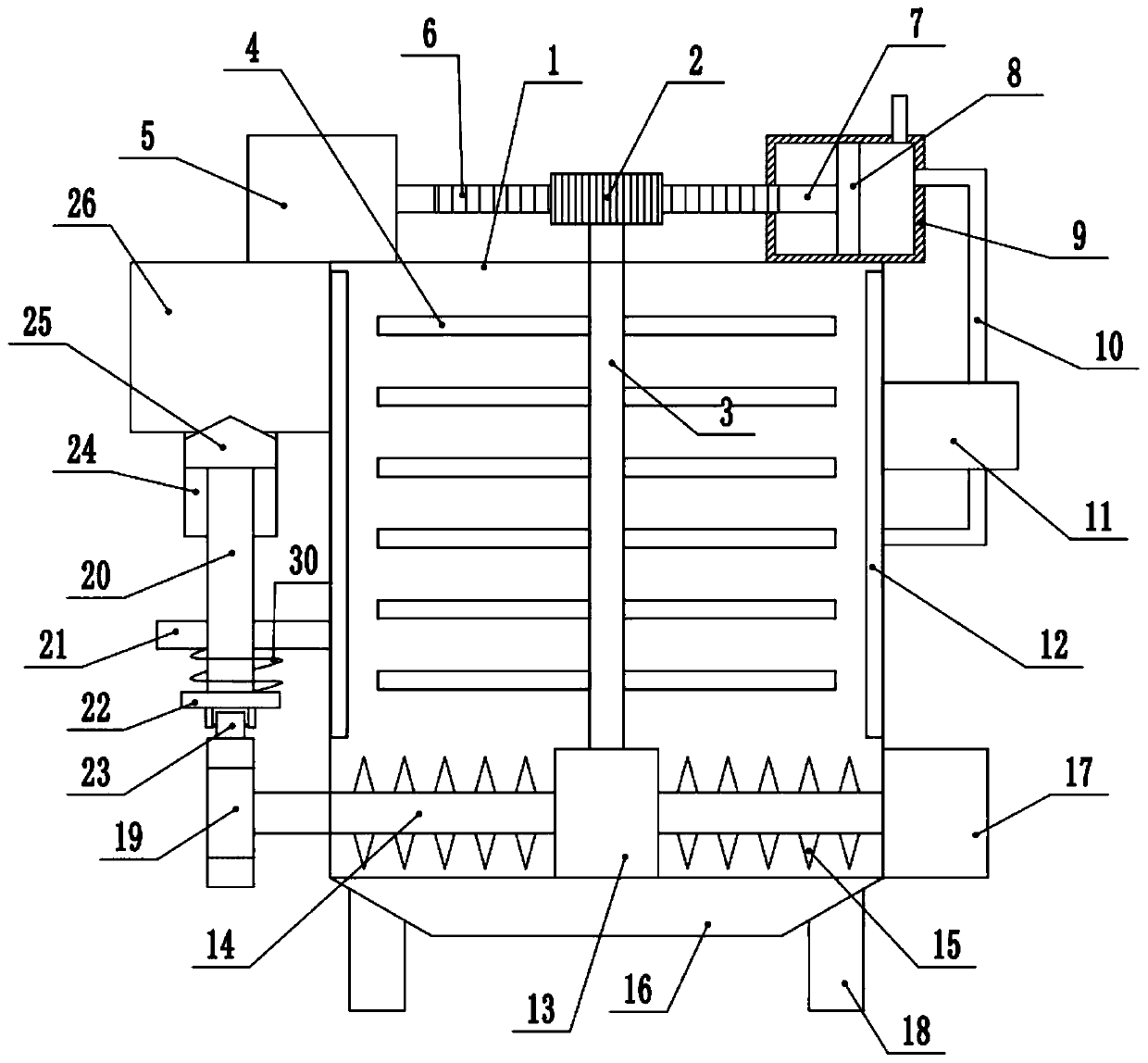

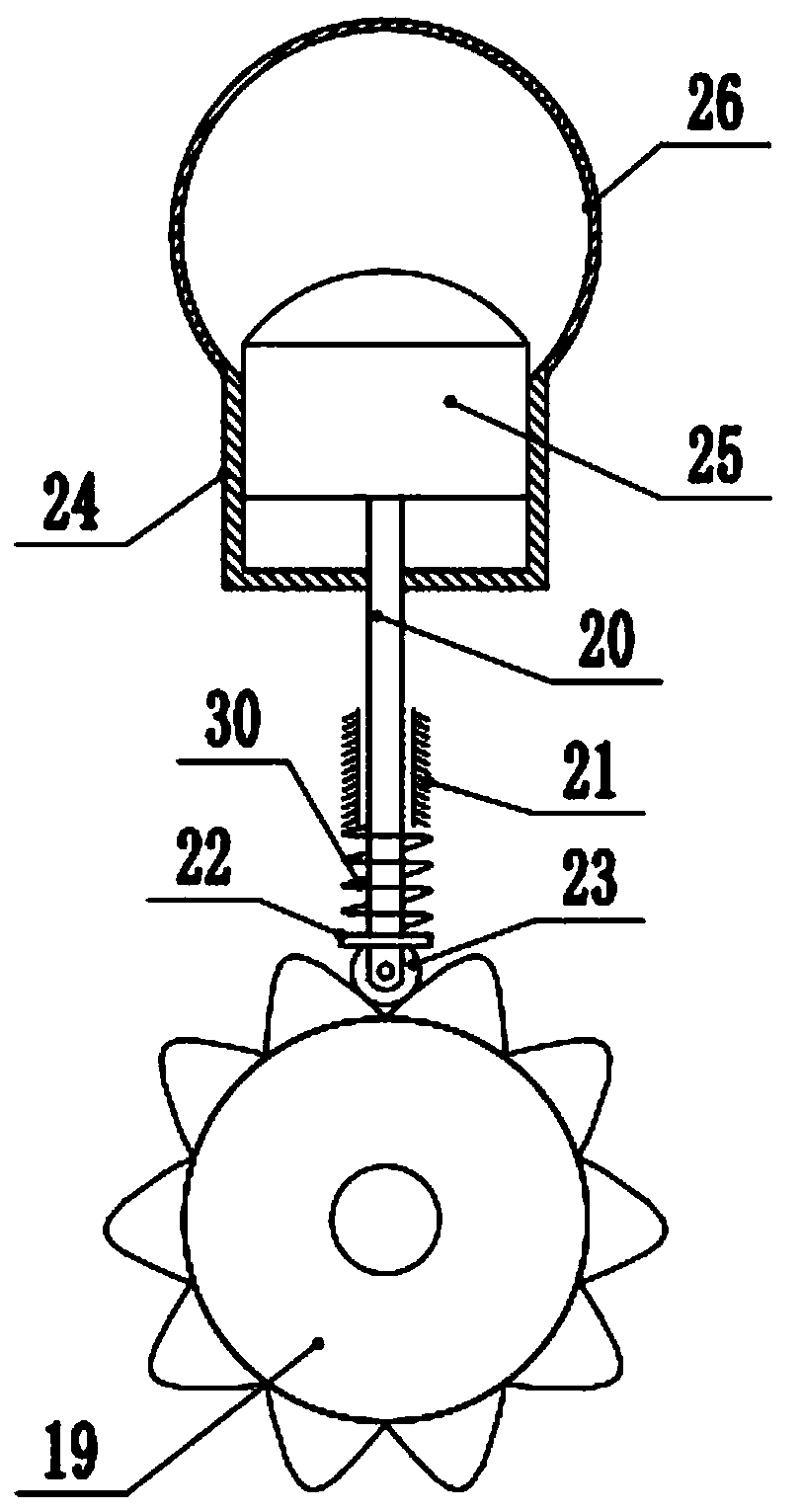

[0031] refer to Figure 1~5 , in an embodiment of the present invention, a high-efficiency forage pulverizer for cotton stalks includes a crushing box 1, a discharge hopper 16 is connected to the middle of the lower end of the crushing box 1, and is used to discharge materials after processing and crushing, and the lower end of the crushing box 1 is Support legs 18 are installed on both sides to support and fix the entire device. A crushing shaft 3 is installed inside the crushing box 1, and several crushing leaves 4 are arranged on the outside of the crushing shaft 3 for crushing straw. , the bottom end of the crushing shaft 3 is connected with a gear box 13, and the inside of the gear box 13 is equipped with a set of bevel gears meshing with each other, so that the torque of the cutting shaft 14 can be transmitted to the crushing shaft 3, so that the crushing shaft 3 can rotate synchronously, Gear box 13 horizontal position is connected with cutting shaft 14, and the outside...

Embodiment 2

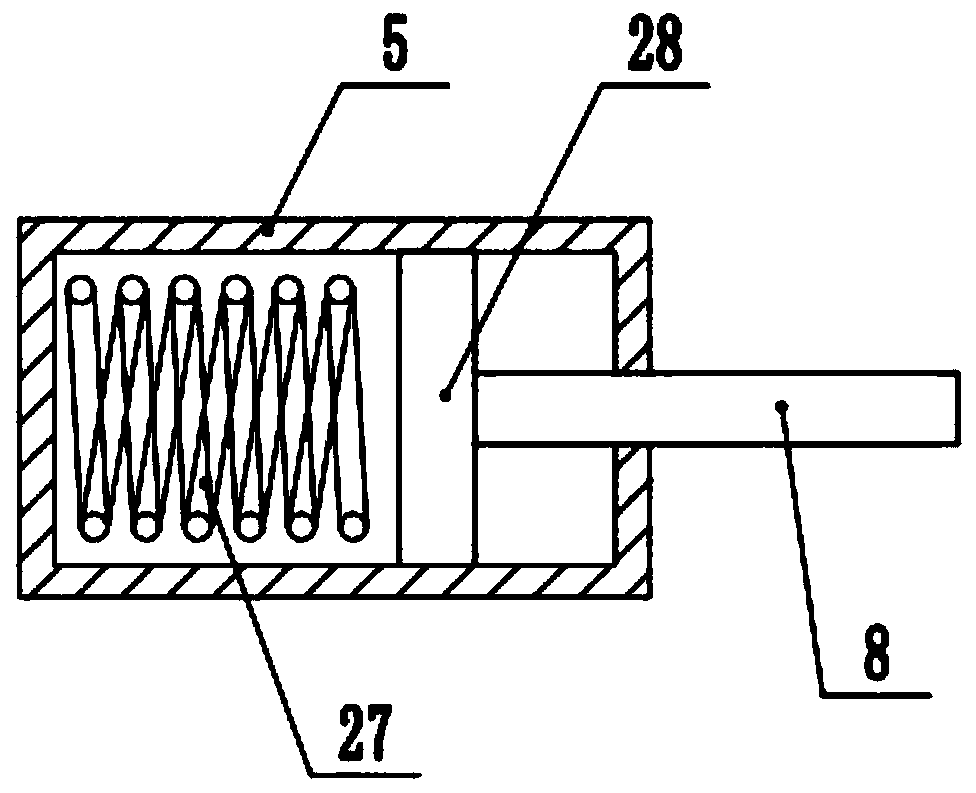

[0033] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a limiting cylinder 5 is installed on the left side of the upper end of the crushing box 1, and a moving rod 7 is arranged inside the limiting cylinder 5, and the moving rod 7. The front end is provided with a rack 6. The right end of the moving rod 7 is connected with a piston plate 8. The piston plate 8 can move left and right along the piston box 9. The piston box 9 is installed on the outside of the piston plate 8. The right end of the piston box 9 is connected with a The air guide chamber 12 fixed inside the crushing box 1 is provided with several air guide holes 29 inside the air guide chamber 12, and then hot air is introduced into the inside of the crushing box 3 to dry the straw feed, reduce the internal moisture of the feed, and further improve Feed quality, a heating box 11 is installed in the middle of the air duct 10, and a heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com