Treatment method for hydrochloric acid production tail gas

A treatment method and tail gas technology are applied in the chemical industry to achieve the effects of avoiding excessively high aggregation temperature, absorbing hydrochloric acid tail gas well, and improving tail gas absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

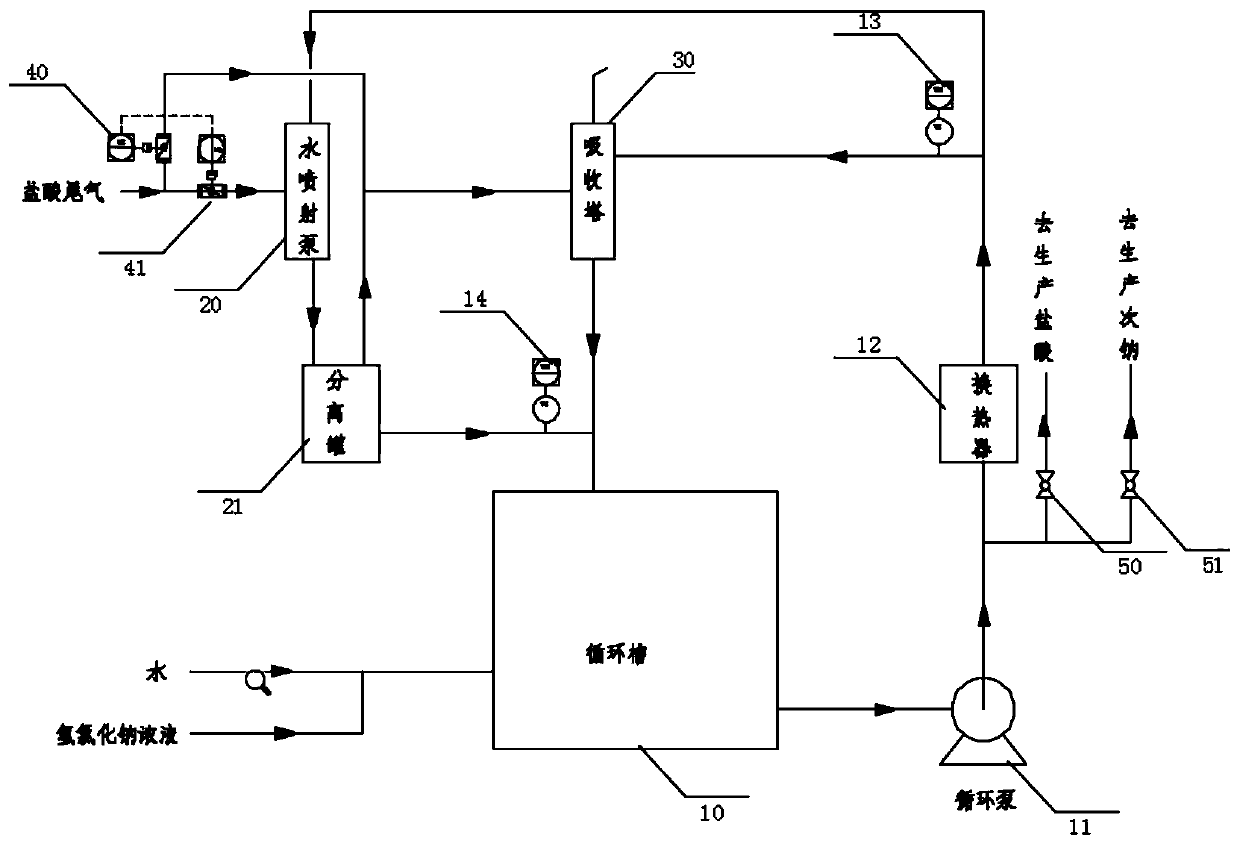

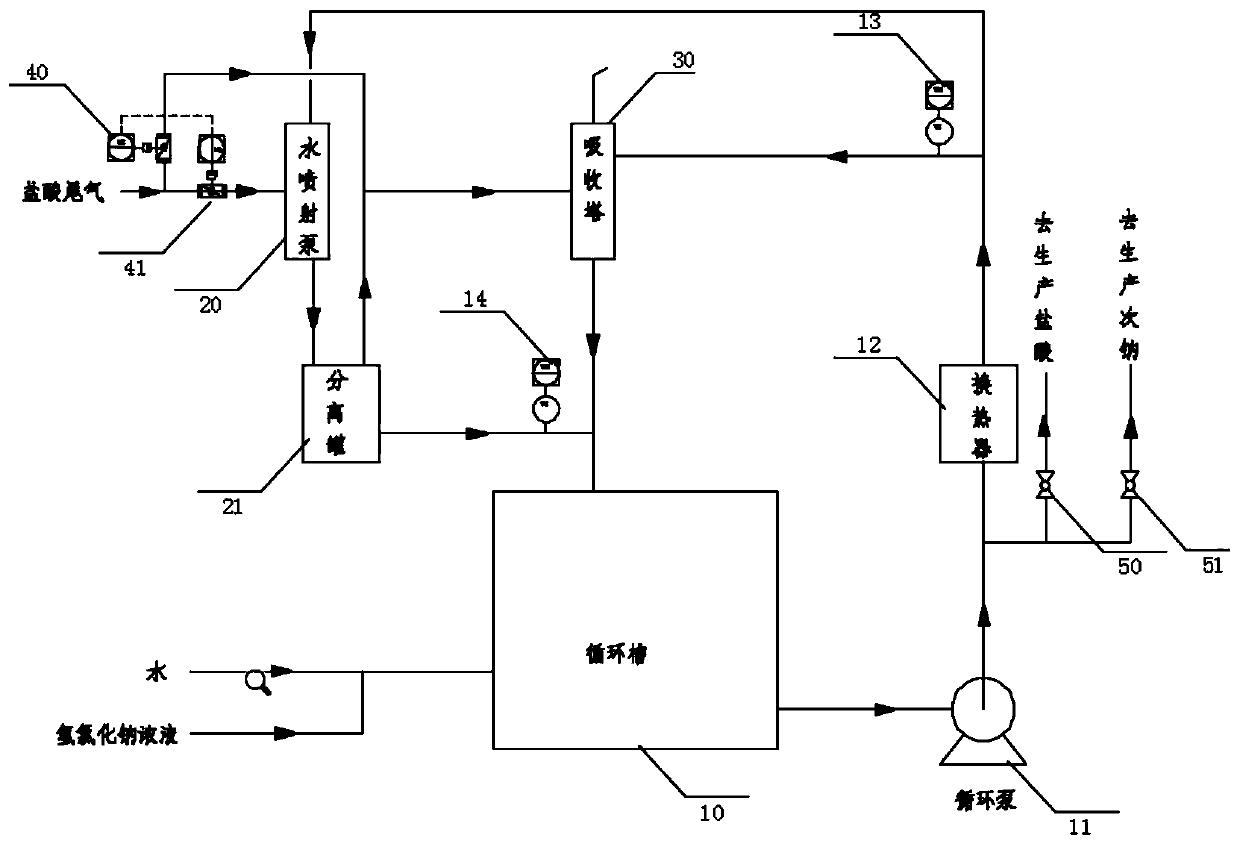

[0042] A treatment method for hydrochloric acid tail gas, its production process is as follows figure 1 shown, including the following steps:

[0043] S1. Spray vacuuming: The absorption liquid is pumped from the circulation tank to the spray absorption device to absorb the hydrochloric acid tail gas generated by the point furnace, and provide a vacuum for the synthesis furnace system. The vacuum degree is -50KPa, absorbing liquid gas and liquid The separated exhaust gas enters the exhaust gas absorption device, and the liquid enters the circulation tank;

[0044] S2. Tail gas absorption: pump the absorption liquid from the circulation tank to the tail gas absorption device under pressure, and countercurrently absorb the tail gas after gas-liquid separation;

[0045] S3. Tail gas absorption switching: After the synthesis furnace is in normal operation, switch the generated hydrochloric acid tail gas to the tail gas absorption device for countercurrent absorption, and stop ent...

Embodiment 2

[0060] A treatment method for hydrochloric acid tail gas, its production process is as follows figure 1 shown, including the following steps:

[0061] S1. Spray vacuuming: pump the absorption liquid from the circulation tank to the spray absorption device to absorb the hydrochloric acid tail gas generated by the point furnace, and provide a vacuum for the synthesis furnace system. The vacuum degree is -10KPa, and the absorption liquid, gas and liquid The separated exhaust gas enters the exhaust gas absorption device, and the liquid enters the circulation tank;

[0062] S2. Exhaust gas absorption: the absorption liquid is pumped from the circulation tank to the exhaust gas absorption device, and the exhaust gas after gas-liquid separation is absorbed countercurrently;

[0063] S3. Tail gas absorption switching: After the synthesis furnace is in normal operation, switch the generated hydrochloric acid tail gas to the tail gas absorption device for countercurrent absorption, and...

Embodiment 3

[0074] A treatment method for hydrochloric acid tail gas, its production process is as follows figure 1 shown, including the following steps:

[0075] S1. Spray vacuuming: pump the absorption liquid from the circulation tank to the spray absorption device to absorb the hydrochloric acid tail gas generated by the point furnace, and provide a vacuum for the synthesis furnace system. The vacuum degree is -10KPa, and the absorption liquid, gas and liquid The separated exhaust gas enters the exhaust gas absorption device, and the liquid enters the circulation tank;

[0076] S2. Exhaust gas absorption: the absorption liquid is pumped from the circulation tank to the exhaust gas absorption device, and the exhaust gas after gas-liquid separation is absorbed countercurrently;

[0077] S3. Tail gas absorption switching: After the synthesis furnace is in normal operation, switch the generated hydrochloric acid tail gas to the tail gas absorption device for countercurrent absorption, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com