Tungsten trioxide/vanadium dioxide composite powder with thermochromic performance and preparation method and application of tungsten trioxide/vanadium dioxide composite powder

A thermochromic, composite powder technology, applied in the direction of tungsten oxide/tungsten hydroxide, vanadium oxide, etc., can solve the problems of complex preparation process chemical vapor deposition method, achieve obvious thermochromic effect, good thermochromic performance, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

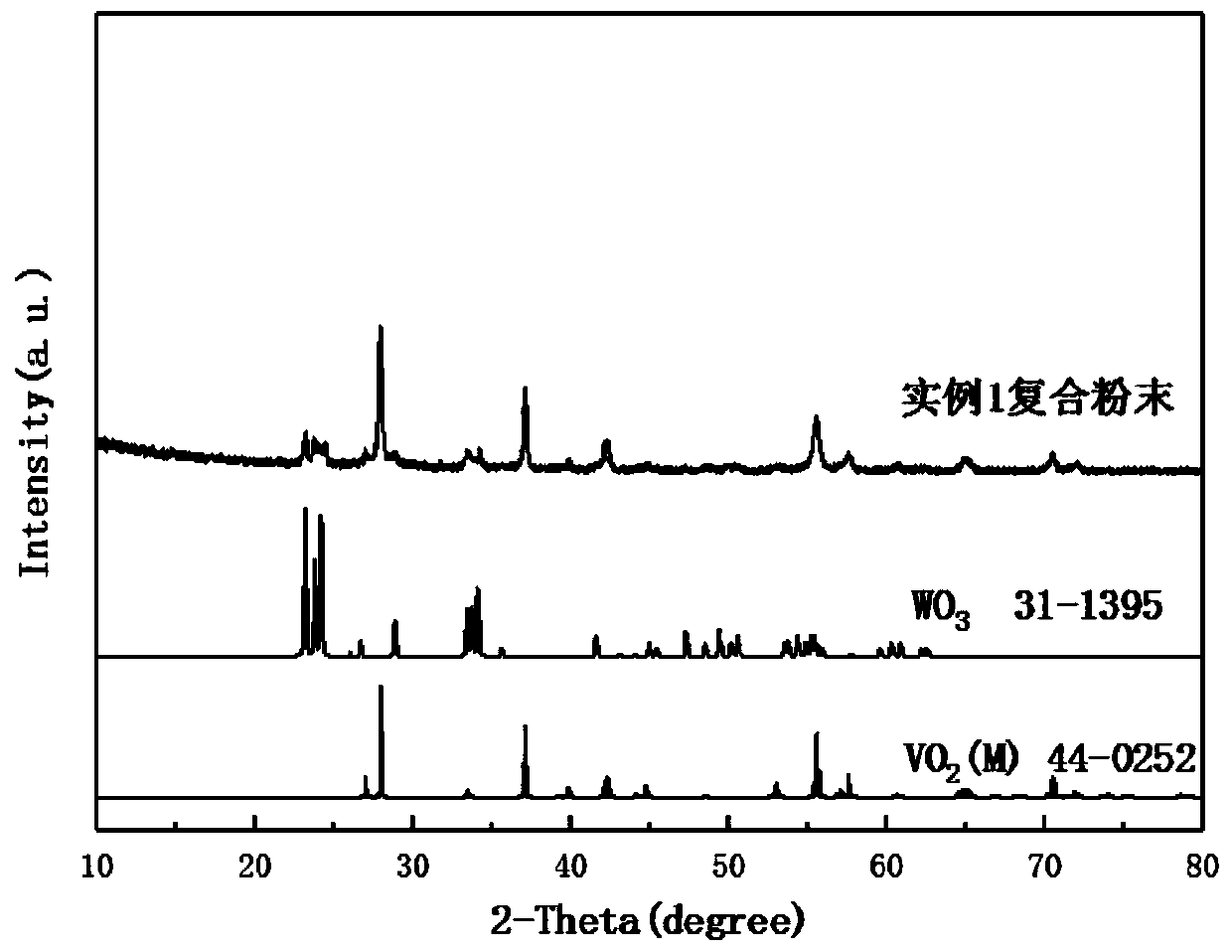

[0036] Preparation of WO 3 / VO 2 Composite powder, the steps are as follows:

[0037] (1) Weigh 0.4g of vanadium pentoxide and 0.025g of ammonium tungstate and place them in a mortar, grind for 15min to mix them evenly, and put them into a corundum crucible;

[0038] (2) take by weighing 0.2g ammonium bicarbonate and place in another corundum crucible;

[0039] (3) Put the corundum crucible in (1) and (2) into a vacuum tube furnace with a vacuum degree of 50 Pa, raise the temperature to 550°C at 10°C / min, keep it warm for 30min, and cool it down to room temperature with the furnace after the heat preservation is completed. WO 3 / VO 2 Composite powder.

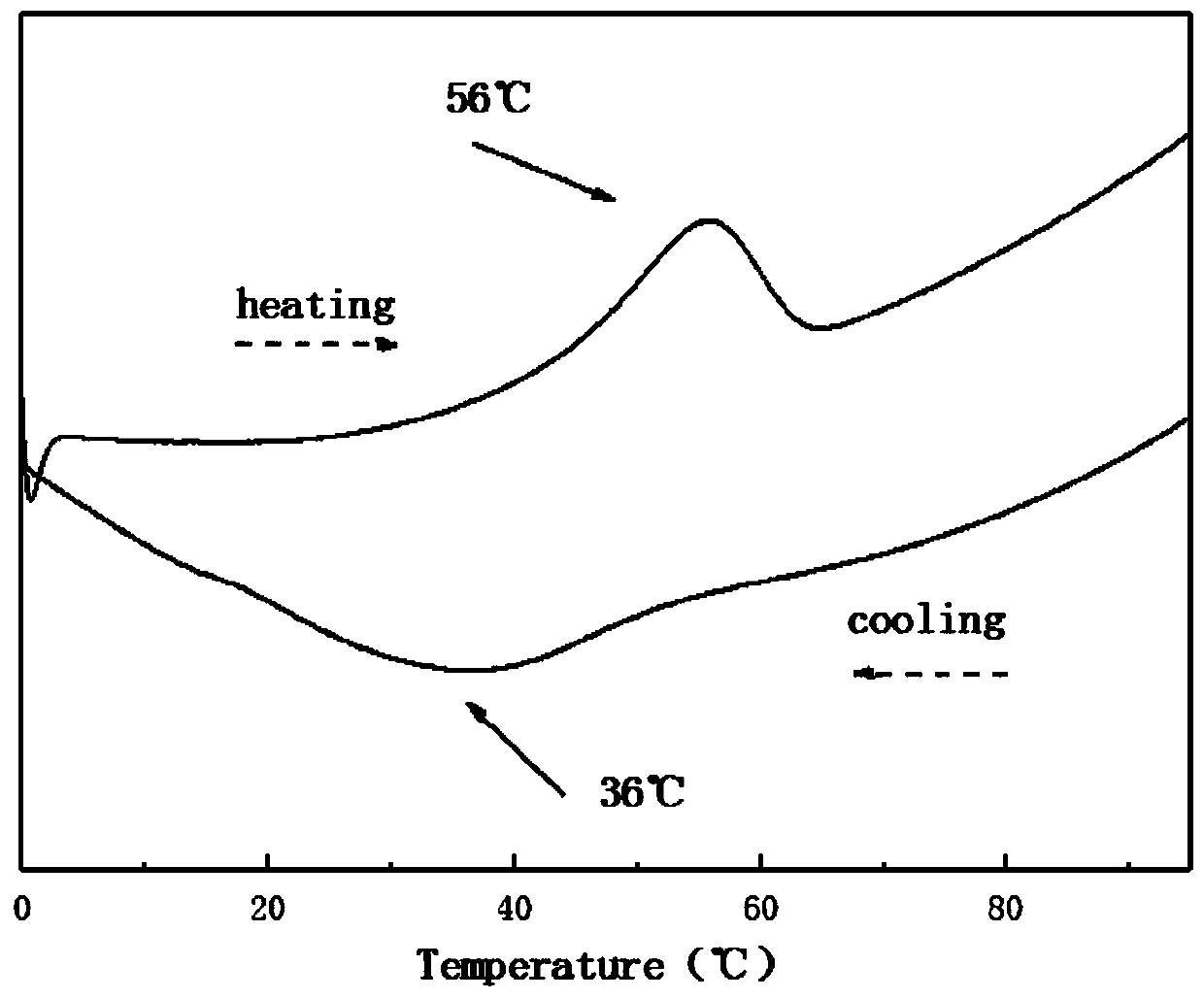

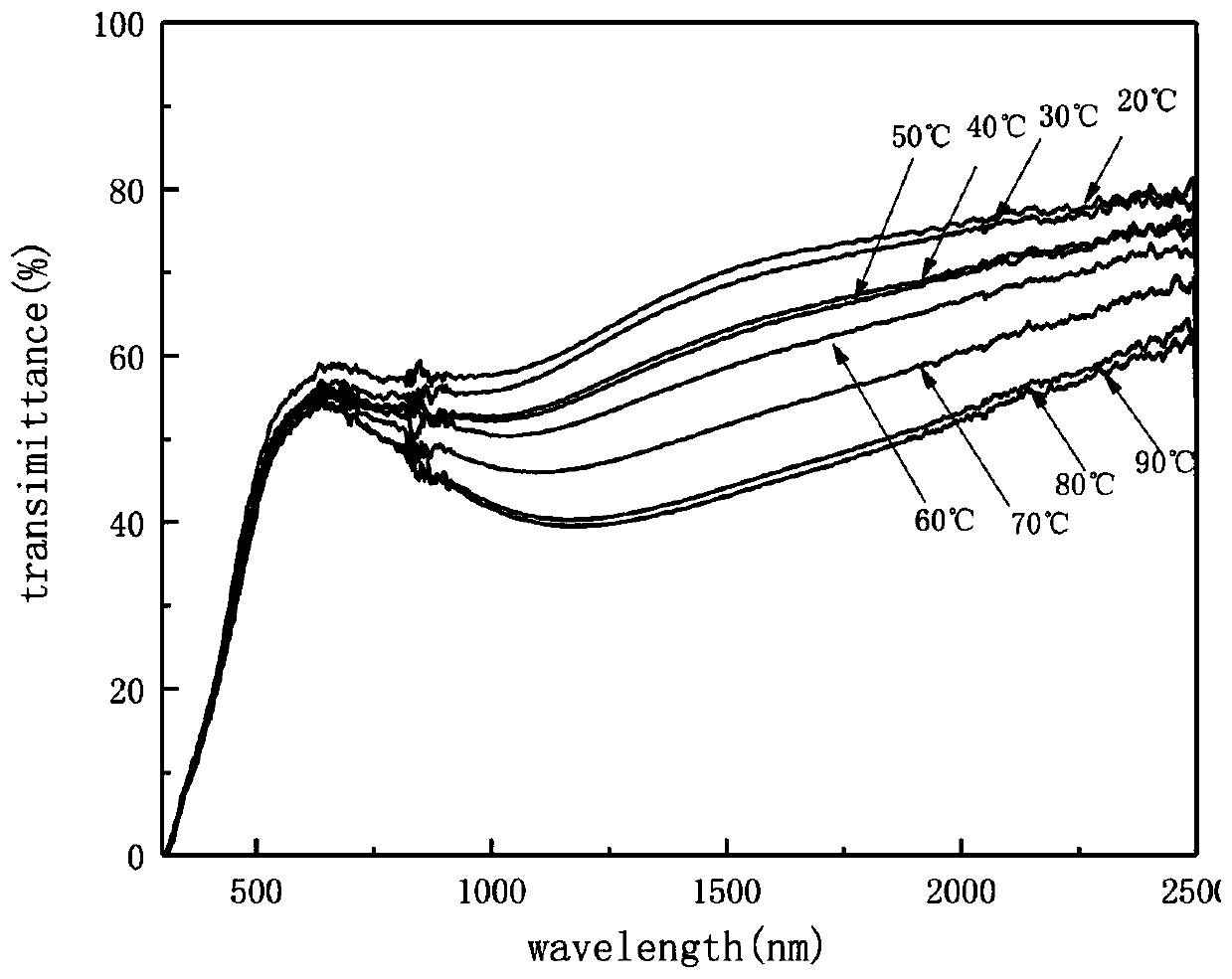

[0040] The thermochromic properties of the obtained composite powder were characterized by spin coating method:

[0041] (4) When 0.3 g of the composite powder obtained in step (3) is ball milled and mixed with 0.15 g of PVP and 8 ml of ethanol solution for 8 hours, the mixture is centrifuged at a speed of 8000 r / min for ...

Embodiment 2

[0045] Preparation of WO 3 / VO 2 Composite powder, the steps are as follows:

[0046] (1) Weigh 0.4g of vanadium pentoxide and 0.1g of ammonium tungstate and place them in a mortar, grind for 15min to make them evenly mixed, and then put them into a corundum crucible;

[0047] (2) take by weighing 0.2g ammonium bicarbonate and place in another corundum crucible;

[0048] (3) Put the corundum crucible in (1) and (2) into a vacuum tube furnace with a vacuum degree of 50 Pa, raise the temperature to 550°C at 10°C / min, keep it warm for 30min, and cool it down to room temperature with the furnace after the heat preservation is completed. WO 3 / VO 2 Composite powder.

[0049] The thermochromic properties of the obtained composite powder were characterized by spin coating method:

[0050] (4) When 0.3 g of the composite powder obtained in step (3) is ball milled and mixed with 0.15 g of PVP and 8 ml of ethanol solution for 8 hours, the mixture is centrifuged at a speed of 8000 ...

Embodiment 3

[0054] Preparation of WO 3 / VO 2 Composite powder, the steps are as follows:

[0055] (1) Weigh 0.4g vanadium pentoxide and 0.05g ammonium tungstate and place them in a mortar, grind for 15min to mix them evenly, and put them in a corundum crucible;

[0056] (2) take by weighing 0.2g ammonium bicarbonate and place in another corundum crucible;

[0057] (3) Put the corundum crucible in (1) and (2) into a vacuum tube furnace with a vacuum degree of 50 Pa, raise the temperature to 550°C at 10°C / min, keep it warm for 30min, and cool it down to room temperature with the furnace after the heat preservation is completed. WO 3 / VO 2 Composite powder.

[0058] The thermochromic properties of the obtained composite powder were characterized by spin coating method:

[0059] (4) When 0.3 g of the composite powder obtained in step (3) is ball milled and mixed with 0.15 g of PVP and 8 ml of ethanol solution for 8 hours, the mixture is centrifuged at a speed of 8000 r / min for 4 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com