Method for preparing vanadium dioxide thin film by magnetron sputtering at low temperature

A technology of vanadium dioxide and magnetron sputtering, which is applied in sputtering plating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of slow deposition rate and low production efficiency, and achieve lower preparation temperature, Energy saving, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

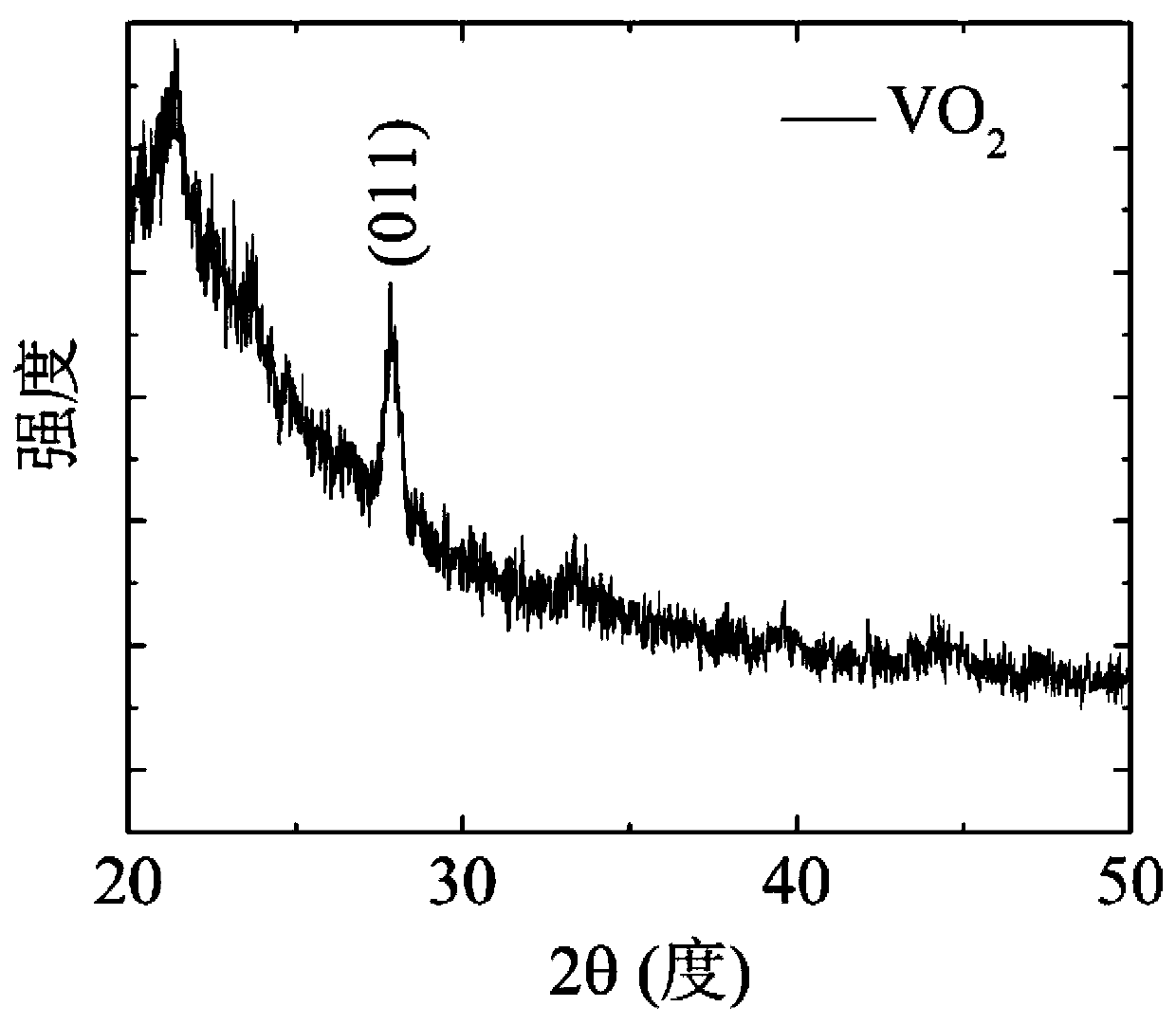

Embodiment 1

[0040] The substrate is ordinary float glass or quartz glass. The substrate was ultrasonically cleaned with acetone, isopropanol, and deionized water for 5 minutes, then dried with a nitrogen gun, fixed on the sample stage, and placed in a transitional vacuum chamber for vacuuming. The pumping is below 5Pa, and the glass substrate is introduced into the sputtering chamber through the pneumatic transfer rod. Turn on the substrate heating system, heat the glass sheet to 190°C, and keep the temperature constant.

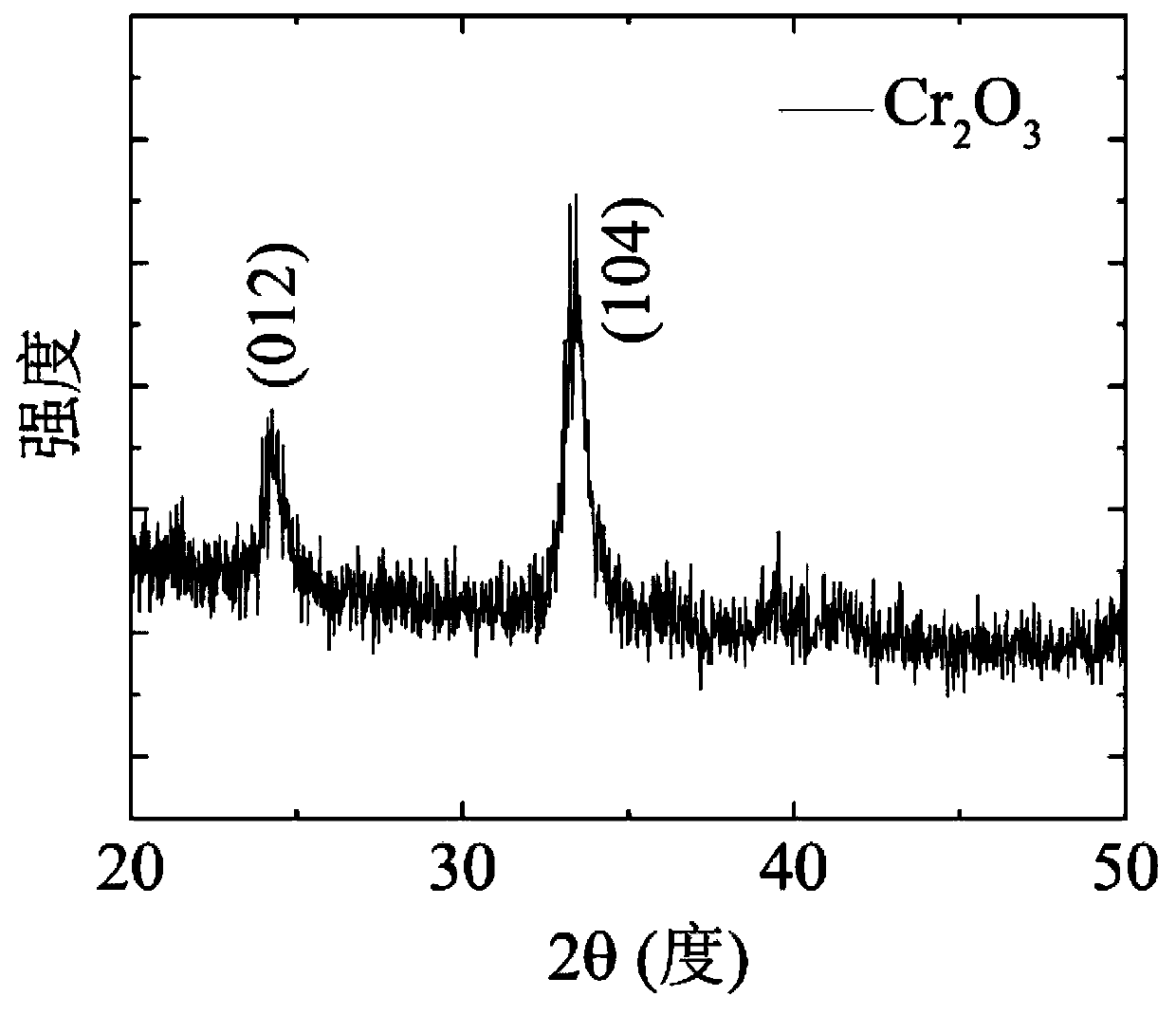

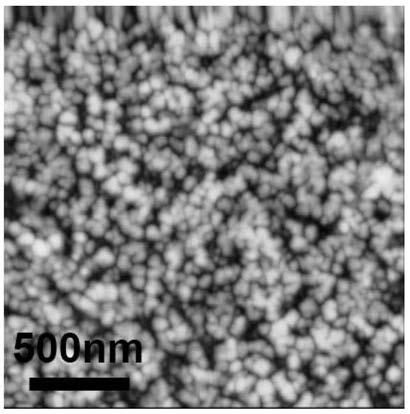

[0041] Cr first 2 o 3 The preparation of the buffer layer, the preparation conditions are as follows: use Cr 2 o 3 Ceramic target, the working atmosphere is high-purity Ar gas (purity higher than 99.999%), injected into the sputtering chamber at a gas flow rate of 50sccm, the working pressure is kept at 0.5Pa, the RF sputtering power is set to 120w, and the sputtering time is 40 Minutes, at this time the Cr on the glass substrate 2 o 3 The thickness is about 30nm...

Embodiment 2

[0044] The substrate is ordinary float glass or quartz glass. The substrate was ultrasonically cleaned with acetone, isopropanol, and deionized water for 5 minutes, then dried with a nitrogen gun, fixed on the sample stage, and placed in a transitional vacuum chamber for vacuuming. The pumping is below 5Pa, and the glass substrate is introduced into the sputtering chamber through the pneumatic transfer rod. Turn on the substrate heating system, heat the glass sheet to 150°C, and keep the temperature constant.

[0045] Cr first 2 o 3 The preparation of the buffer layer, the preparation conditions are as follows: use Cr 2 o 3 Ceramic target, the working atmosphere is high-purity Ar gas (purity higher than 99.999%), injected into the sputtering chamber at a gas flow rate of 50sccm, the working pressure is kept at 0.5Pa, the RF sputtering power is set to 120w, and the sputtering time is 40 Minutes, at this time the Cr on the glass substrate 2 o 3 The thickness is about 30nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com