A composite powder of tungsten trioxide/vanadium dioxide with thermochromic properties and its preparation method and application

A thermochromic and composite powder technology, which is applied in the direction of tungsten oxide/tungsten hydroxide, vanadium oxide, etc., can solve the problems of complex chemical vapor deposition in the preparation process, and achieve obvious thermochromic effect, low equipment requirements, good thermal Effect of Chromogenic Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

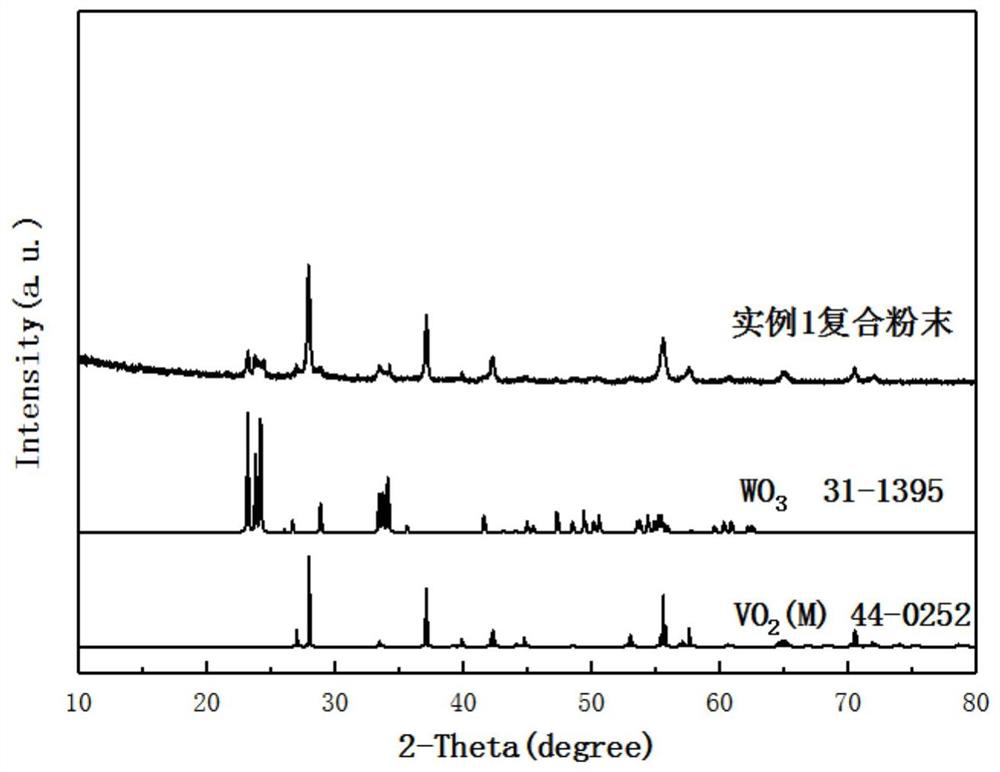

[0036] Preparation of WO 3 / VO 2 Composite powder, the steps are as follows:

[0037] (1) Weigh 0.4g of vanadium pentoxide and 0.025g of ammonium tungstate and place them in a mortar, grind for 15min to mix them evenly, and put them into a corundum crucible;

[0038] (2) take by weighing 0.2g ammonium bicarbonate and place in another corundum crucible;

[0039] (3) put the corundum crucible in (1) and (2) into the vacuum tube furnace, the vacuum degree is 50pa, with

[0040] 10°C / min to raise the temperature to 550°C, hold the temperature for 30 minutes, and cool down to room temperature with the furnace after the heat preservation is over to obtain WO 3 / VO 2 Composite powder.

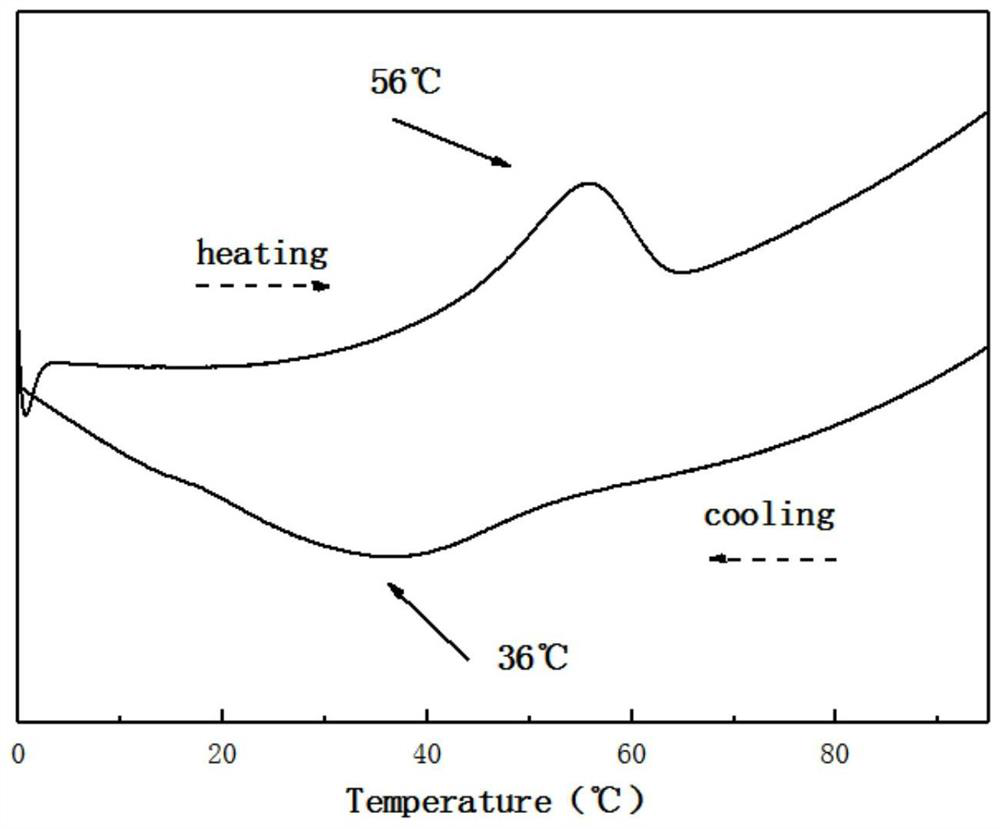

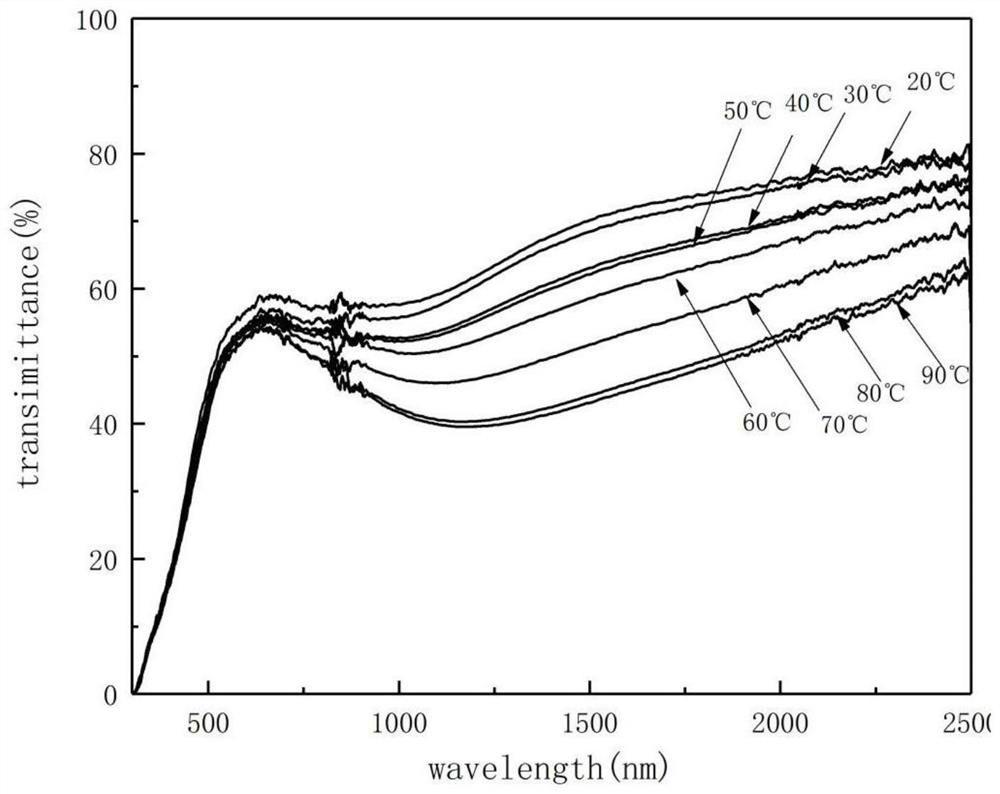

[0041] The thermochromic properties of the obtained composite powder were characterized by spin coating method:

[0042] (4) When 0.3 g of the composite powder obtained in step (3) is ball milled and mixed with 0.15 g of PVP and 8 ml of ethanol solution for 8 hours, the mixture is centrifuged at...

Embodiment 2

[0046] Preparation of WO 3 / VO 2 Composite powder, the steps are as follows:

[0047] (1) Weigh 0.4g of vanadium pentoxide and 0.1g of ammonium tungstate and place them in a mortar, grind for 15min to make them evenly mixed, and then put them into a corundum crucible;

[0048] (2) take by weighing 0.2g ammonium bicarbonate and place in another corundum crucible;

[0049] (3) Put the corundum crucible in (1) and (2) into a vacuum tube furnace with a vacuum degree of 50 Pa, raise the temperature to 550°C at 10°C / min, keep it warm for 30min, and cool it down to room temperature with the furnace after the heat preservation is completed. WO 3 / VO 2 Composite powder.

[0050] The thermochromic properties of the obtained composite powder were characterized by spin coating method:

[0051] (4) When 0.3 g of the composite powder obtained in step (3) is ball milled and mixed with 0.15 g of PVP and 8 ml of ethanol solution for 8 hours, the mixture is centrifuged at a speed of 8000 ...

Embodiment 3

[0055] Preparation of WO 3 / VO 2 Composite powder, the steps are as follows:

[0056] (1) Weigh 0.4g vanadium pentoxide and 0.05g ammonium tungstate and place them in a mortar, grind for 15min to mix them evenly, and put them in a corundum crucible;

[0057] (2) take by weighing 0.2g ammonium bicarbonate and place in another corundum crucible;

[0058] (3) Put the corundum crucible in (1) and (2) into a vacuum tube furnace with a vacuum degree of 50 Pa, raise the temperature to 550°C at 10°C / min, keep it warm for 30min, and cool it down to room temperature with the furnace after the heat preservation is completed. WO 3 / VO 2 Composite powder.

[0059] The thermochromic properties of the obtained composite powder were characterized by spin coating method:

[0060] (4) When 0.3 g of the composite powder obtained in step (3) is ball milled and mixed with 0.15 g of PVP and 8 ml of ethanol solution for 8 hours, the mixture is centrifuged at a speed of 8000 r / min for 4 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com