Method for producing rare earth microelement fertilizer by using remediation plant Dicranopteris dichotoma, produced Dicranopteris dichotoma ash residue rare earth microelement fertilizer and application

A technology for repairing plants and Osmanthus osmanthus, applied in botany equipment and methods, applications, and land preparation methods, can solve problems such as melting slagging ash fertilizer efficiency, harmful growth and development, and harmful crop growth and development, and achieve the effect of increasing production and quality Good, easy to use, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Optimization of Rare Earth-enriched Osmanthus osmanthus Feather Quality

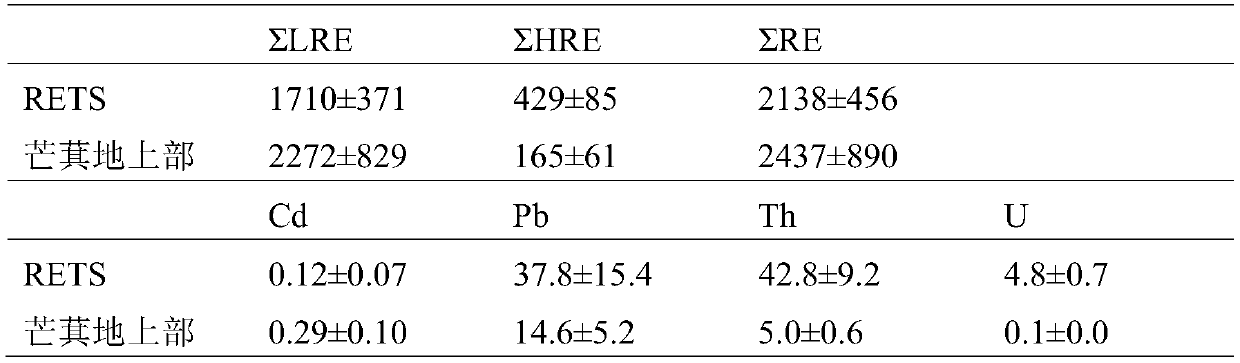

[0032] Select a rare earth tailings area in Lishi Town, Dingnan County, Ganzhou City, Jiangxi Province, and plant Osmanthus in spring, either by transplanting whole plants of Osmanthus or cultivated sporophytes, or by transplanting Osmanthus rhizomes to cultivate Osmanthus for restoration Rare earth tailings pollute the soil. In autumn, the aboveground part of Osmanthus can be collected by harvester or by hand with a sickle. The height of the stubble is about 12-15cm, and the stubble does not need to be treated. At this time, the aboveground part of Osmanthus radiata is the most enriched for rare earths. The contents of rare earths, heavy metals, and radioactive elements in the soil and aboveground parts of Dingnan rare earth tailings in Dingnan County are shown in Table 1.

[0033] Table 1 Rare earth tailings soil (RETS), rare earth content in the aboveground part of Osmanthus fragrans (total rar...

Embodiment 2

[0037] Preparation of Rare Earth Micro Fertilizer from Osmanthus Osmanthus Ash Slag

[0038] Dingnan rich rare earth Osmanthus fragrans leaves harvested in Example 1, after natural air-drying, sent to an oven for drying at 105-110°C, the dried Osmanthus frondosa leaves were pulverized in an agricultural grinder, and the Osmanthus frondosa leaves were dried Incinerate at 815°C or at high temperature at 800°C or 830°C. After drying, crushing, and high-temperature incineration, collect ash and slag, which is Osmanthus ash slag rare earth micro-fertilizer. The industrial analysis method for drying Osmanthus fruticosa leaves is carried out according to the industrial analysis method of GBT 212-2008 coal, and the data are shown in Table 2.

[0039] The dried Osmanthus pinnata leaves were incinerated at 500 and 815°C respectively to obtain Osmanthus ash, and the pH value and main component content were analyzed. The data are shown in Table 3.

[0040] See Table 4 for the contents of...

Embodiment 3

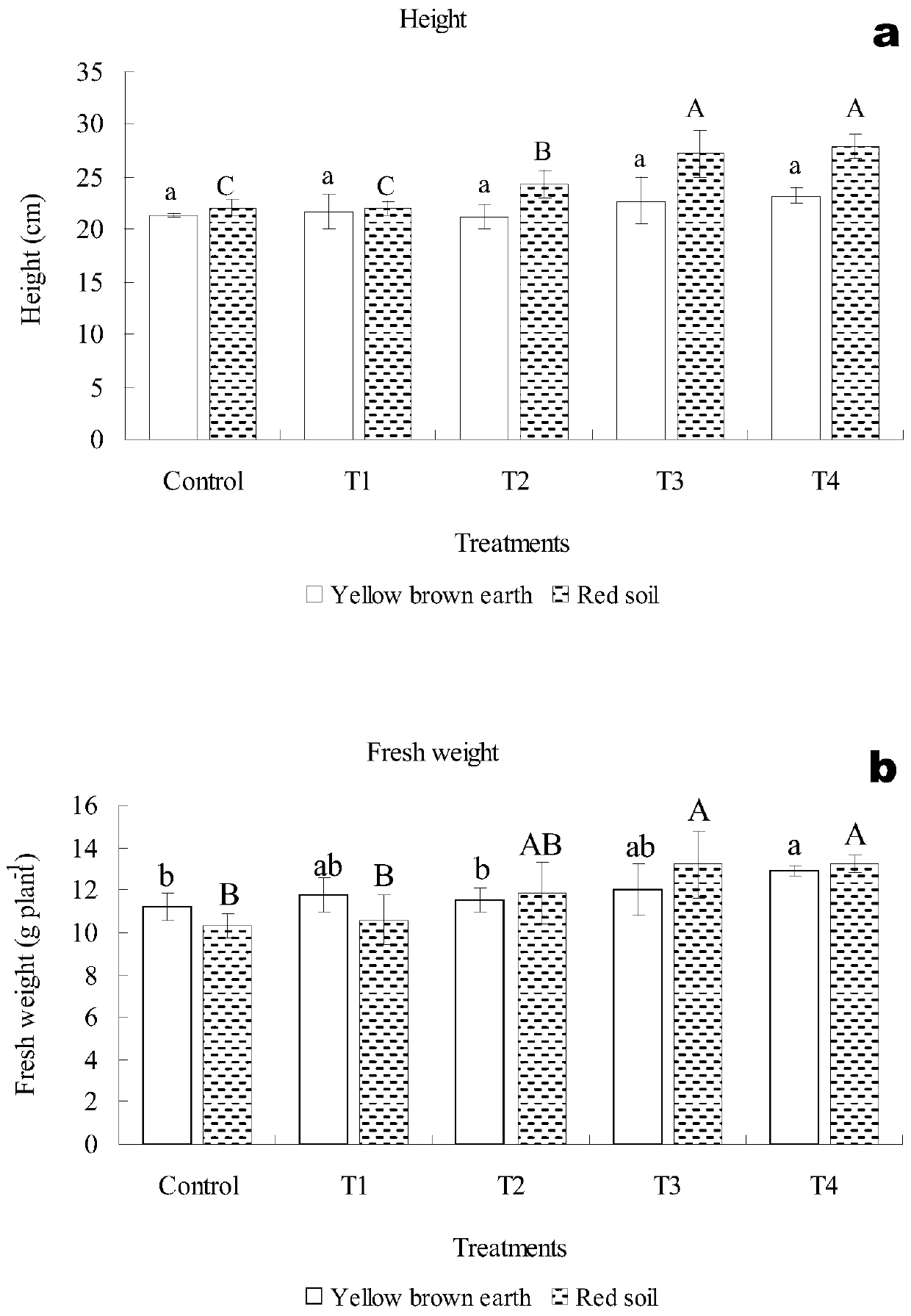

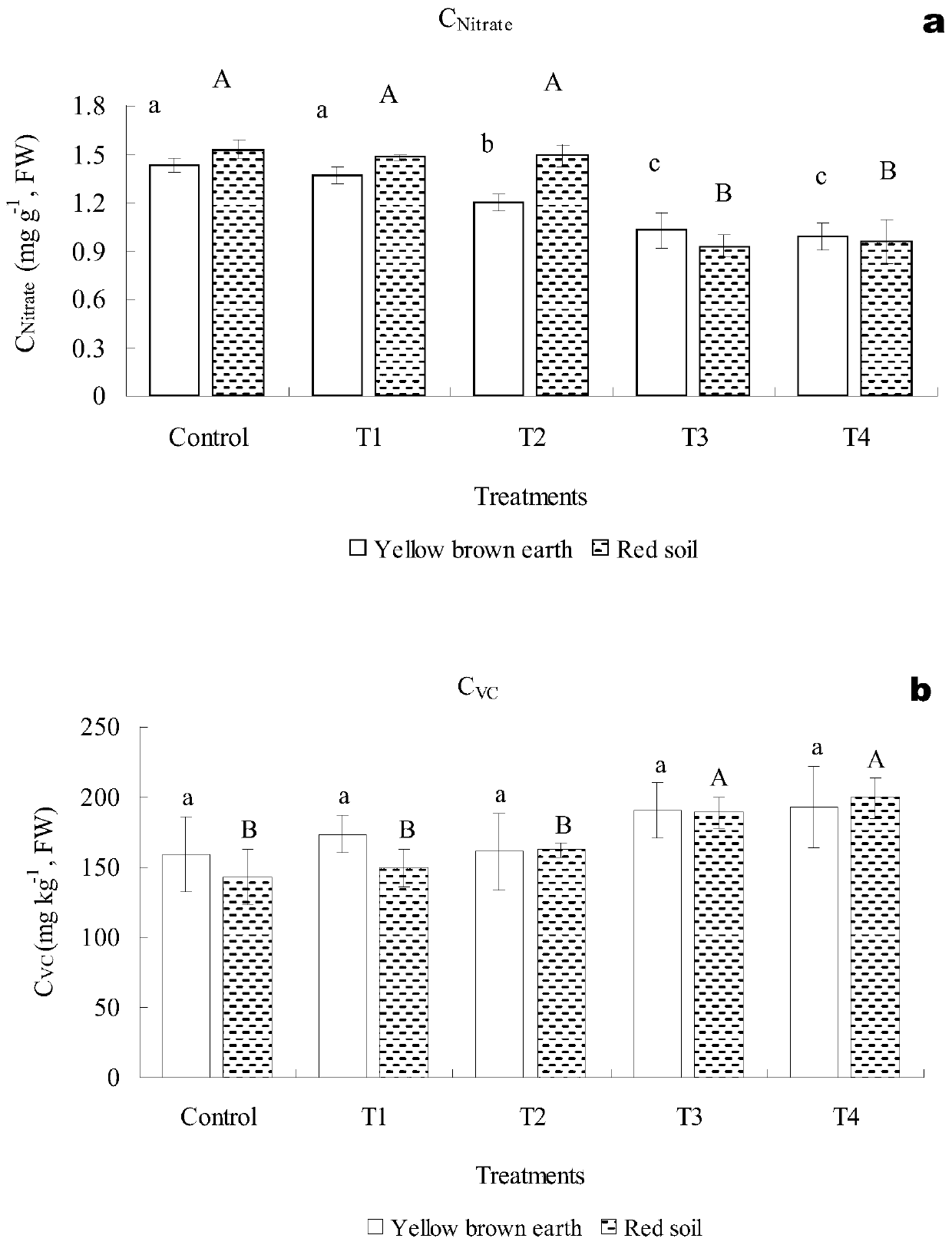

[0050] Rare earth micro-fertilizer from Osmanthus osmanthus ash for cultivation of water spinach in yellow-brown soil

[0051] Get the yellow-brown soil of Nanjing City, Jiangsu Province, press 0.05%, 0.1%, 0.2%, and 0.4% of the dry soil weight respectively to apply the Osmanthus ash and slag rare earth micro-fertilizers produced in Example 2 into the soil, and the dry soil weight is that the soil passes through the oven. The weight of the soil after drying at 105°C, mixed evenly, and placed in a pot for cultivating water spinach. The cultivation experiment was carried out in a greenhouse at 28-35°C with 16 hours of light per day, and the soil weight of each pot was 1.5kg. Four pots are one treatment, 5 seeds are sown in each pot, three seedlings with similar growth are selected after one week of germination, and fertilized according to 15, 15, 20 mg / pot N, P, K (calculated as elements), and continue to cultivate , harvested 35 days after germination. For the growth and deve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com