Cationic starch with ultrahigh substitution degree, and preparation method thereof

A technology of cationic starch and cationic etherification agent, which is applied in the field of materials, can solve the problems of easy gelatinization, difficult post-processing, high degree of substitution of cationic starch, etc., and achieve the effect of improving viscosity reduction efficiency and avoiding low viscosity reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

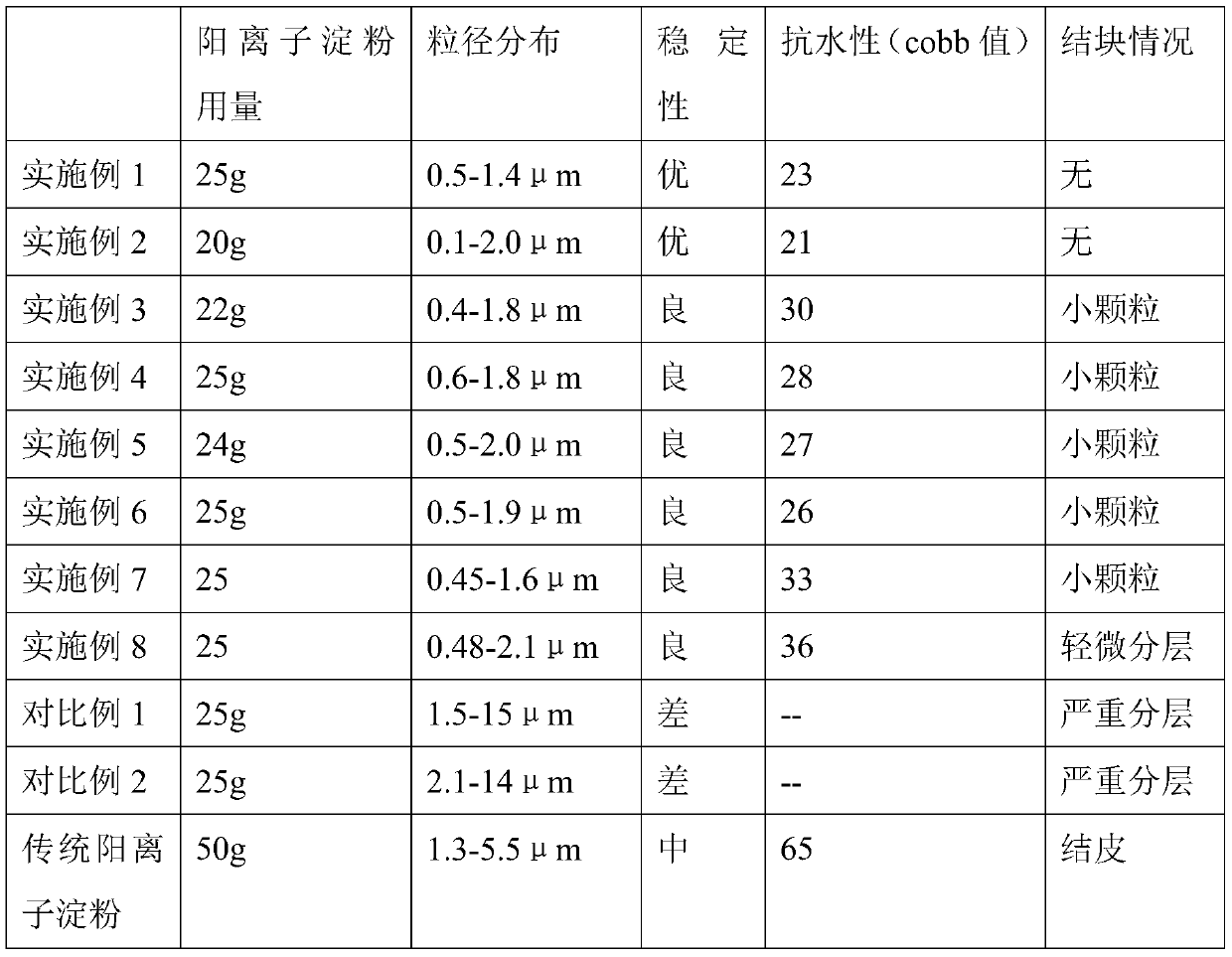

Examples

Embodiment 1

[0034] A method for preparing cationic starch with a super high degree of substitution, the steps are as follows:

[0035] (1) 50 parts by weight of starch (tapioca starch) with a water content between 5% and 15% are added to a mixed solution of 100 parts by weight of water and an organic solvent (the weight ratio is 5:95, and the organic solvent is isopropanol) After stirring evenly, slowly add 5 parts by weight of alkali (sodium hydroxide) into the solution, and stir for 60 minutes.

[0036] (2) The solution was heated to 70° C., and after the temperature stabilized, 1 weight part of hydrogen peroxide (50%) was added to the solution and stirred for 6 hours.

[0037] (3) After adding 0 parts by weight of alkali (sodium hydroxide), 30 parts by weight of 2,3-epoxypropyltrimethylammonium chloride was added. The stirring reaction was continued for 1 hour.

[0038] (4) Add an appropriate amount of acid (acetic acid) after the reaction to neutralize the reaction. After being was...

Embodiment 2

[0040] (1) 50 parts by weight of starch (tapioca starch) with a water content between 5% and 15% are added to a mixed solution of 100 parts by weight of water and an organic solvent (the weight ratio is 40:60, and the organic solvent is isopropanol) After stirring evenly, slowly add 0.1 parts by weight of alkali (sodium hydroxide) into the solution, and stir for 60 minutes.

[0041] (2) The solution was heated to 40° C., and after the temperature stabilized, 25 parts of hydrogen peroxide (50%) was added to the solution and stirred for 0.5 hours.

[0042] (3) After adding 5 parts by weight of alkali (sodium hydroxide), 90 parts by weight of 2,3-epoxypropyltrimethylammonium chloride was added. The stirring reaction was continued for 6 hours.

[0043] (4) Add an appropriate amount of acid (acetic acid) after the reaction to neutralize the reaction. After being washed by centrifugation and dried, it is ground into powder to obtain cationic starch with a high degree of substituti...

Embodiment 3

[0045](1) 50 parts by weight of starch (tapioca starch) with a water content between 5% and 15% are added to a mixed solution of 100 parts by weight of water and an organic solvent (the weight ratio is 30:70, and the organic solvent is isopropanol) After stirring evenly, slowly add 2.5 parts by weight of alkali (sodium hydroxide) into the solution, and stir for 60 minutes.

[0046] (2) The solution was heated to 60° C., and after the temperature stabilized, 12.5 parts of hydrogen peroxide (50%) was added to the solution and stirred for 3 hours.

[0047] (3) After adding 2.5 parts by weight of alkali (sodium hydroxide), 60 parts by weight of 2,3-epoxypropyltrimethylammonium chloride was added. The stirring reaction was continued for 3 hours.

[0048] (4) Add an appropriate amount of acid (acetic acid) after the reaction to neutralize the reaction. After being washed by centrifugation and dried, it is ground into powder to obtain cationic starch with a high degree of substitut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com