Heme peptide iron product and preparation method thereof

A technology of heme peptide and heme, applied in the fields of biotechnology and modern agriculture, can solve the problems of high price of metal chelates, narrow application range, specific biological activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

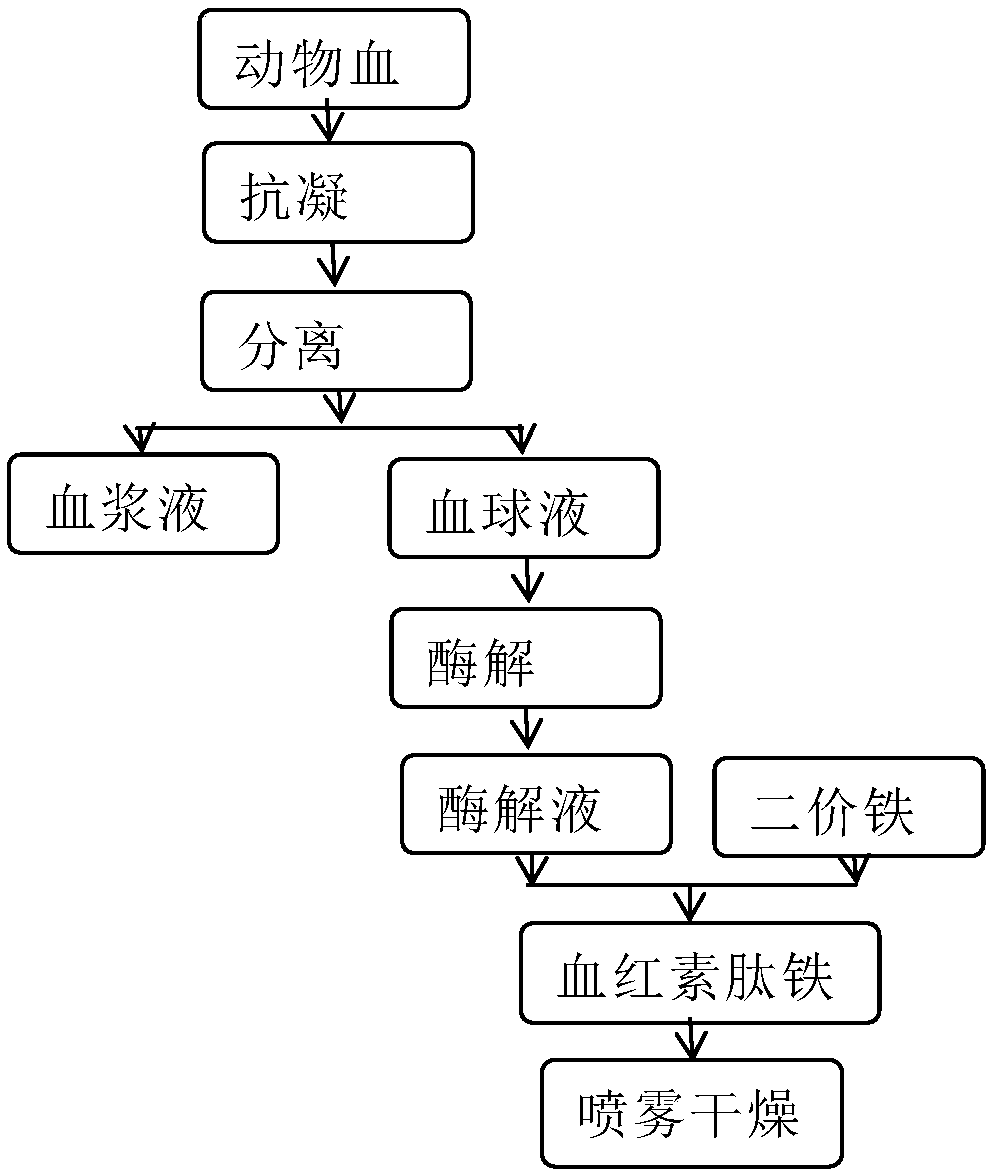

[0038] The preparation method of the heme peptide iron product provided by the present invention uses blood cells obtained by anticoagulation and separation of fresh healthy animal blood as raw materials, and adopts techniques such as enzymatic hydrolysis, chelation, and drying to obtain the heme peptide iron product.

[0039] Specifically, including steps:

[0040] (a) collecting animal blood cells;

[0041] (b) performing enzymatic hydrolysis on the blood cells obtained in step (a) to obtain an enzymatic hydrolysis solution;

[0042] (c) adding divalent iron ions to the enzymolysis solution obtained in step (b) for chelation treatment to obtain a heme peptide iron solution;

[0043] (d) drying the heme peptide iron solution obtained in step (c), thereby obtaining a heme peptide iron product.

[0044] combine figure 1 And preferred embodiment, further set forth the method described in the present invention:

[0045] (a) collecting animal blood cells;

[0046] (b) adjust ...

Embodiment 1

[0059] Preparation of porcine heme peptide iron product 1

[0060] (1) Separating porcine anticoagulant whole blood through a tubular centrifuge (11000 rpm), the resulting light liquid is plasma liquid, and the heavy liquid is blood cell liquid, which is used to prepare porcine heme peptide iron.

[0061] (2) Add 10.0 tons of water to 5.08 tons of the blood cell solution prepared in step (1) and mix and stir, adjust the pH to 10.0 with sodium hydroxide, add 50 kg of alkaline protease and stir for 10 hours at 58° C. to obtain the enzymatic solution;

[0062] (3) Add 1.0 tons of FeCl to the enzymolysis solution 2 4H 2 O stirring and chelating for 3h to obtain a heme peptide iron solution;

[0063] (4) Spray-dry the obtained solution, control the air inlet temperature to 220-240° C., and the air outlet temperature to 90-110° C., so as to obtain the heme peptide iron product.

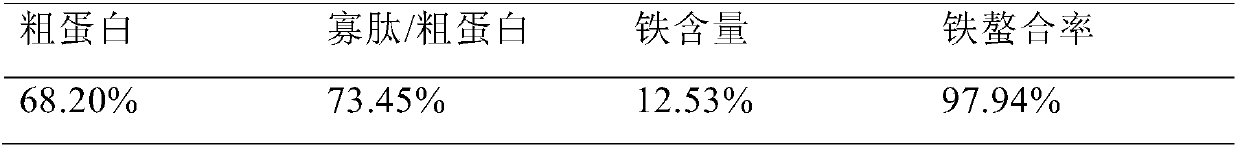

[0064] As a result, using the above method, 5.08 tons of pig blood cells obtained 2.164 tons of heme pe...

Embodiment 2

[0068] Preparation of porcine heme peptide iron product 2

[0069] (1) Separating porcine anticoagulant whole blood through a tubular centrifuge (11000 rpm), the resulting light liquid is plasma liquid, and the heavy liquid is blood cell liquid, which is used to prepare porcine heme peptide iron.

[0070] (2) Add 12.0 tons of water to 5.20 tons of the blood cell solution prepared in step (1) and mix and stir, adjust the pH to 8.5 with sodium hydroxide, add 75 kg of neutral protease and stir for 8 hours at 50°C to obtain an enzymatic solution;

[0071] (3) Add 0.9 tons of FeCl to the enzymolysis solution 2 4H 2 O stirring and chelating for 3h to obtain a heme peptide iron solution;

[0072] (4) Spray-dry the obtained solution, control the air inlet temperature to 230-250° C., and the air outlet temperature to 90-110° C., so as to obtain the heme peptide iron product.

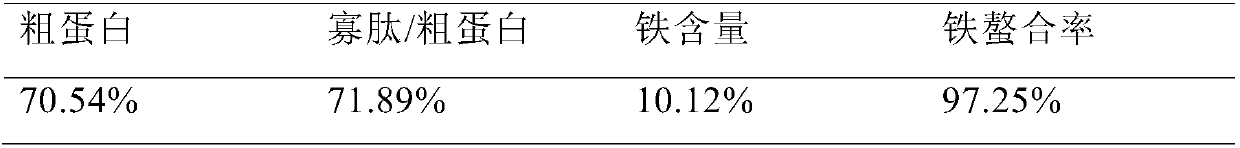

[0073] As a result, using the above method, 5.20 tons of pig blood cells obtained 2.136 tons of heme peptid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com