Composite material, and preparation method and application thereof

A composite material and prefabricator technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, electrical solid-state devices, etc., can solve the problems of unbalanced carrier injection, low efficiency and life, and high production costs, and achieves the goal of suppressing recombination, Improve efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention provides the preparation method of the composite material corresponding to the previous embodiment. The preparation method comprises the steps of:

[0026] Step S11: BiOI is provided, and the surface of BiOI is modified by a coupling agent to obtain modified BiOI.

[0027] In the embodiment of the present invention, in order to improve the compatibility between the polymer and the BiOI particles, the surface is first modified with a coupling agent to promote the subsequent combination of the BiOI particles and PMMA; the coupling agent is specifically a silane coupling agent , which can be methacryloxypropyltrimethoxysilane (MPS), 3-aminopropyltriethoxysilane (APTES) or other silane coupling agents, so that the alkoxy groups it has directly bond with BiOI The hydroxyl groups on the surface react to graft onto the surface of BiOI particles to achieve the purpose of modification.

[0028] Step S12: Disperse the modified BiOI in a p...

Embodiment 1

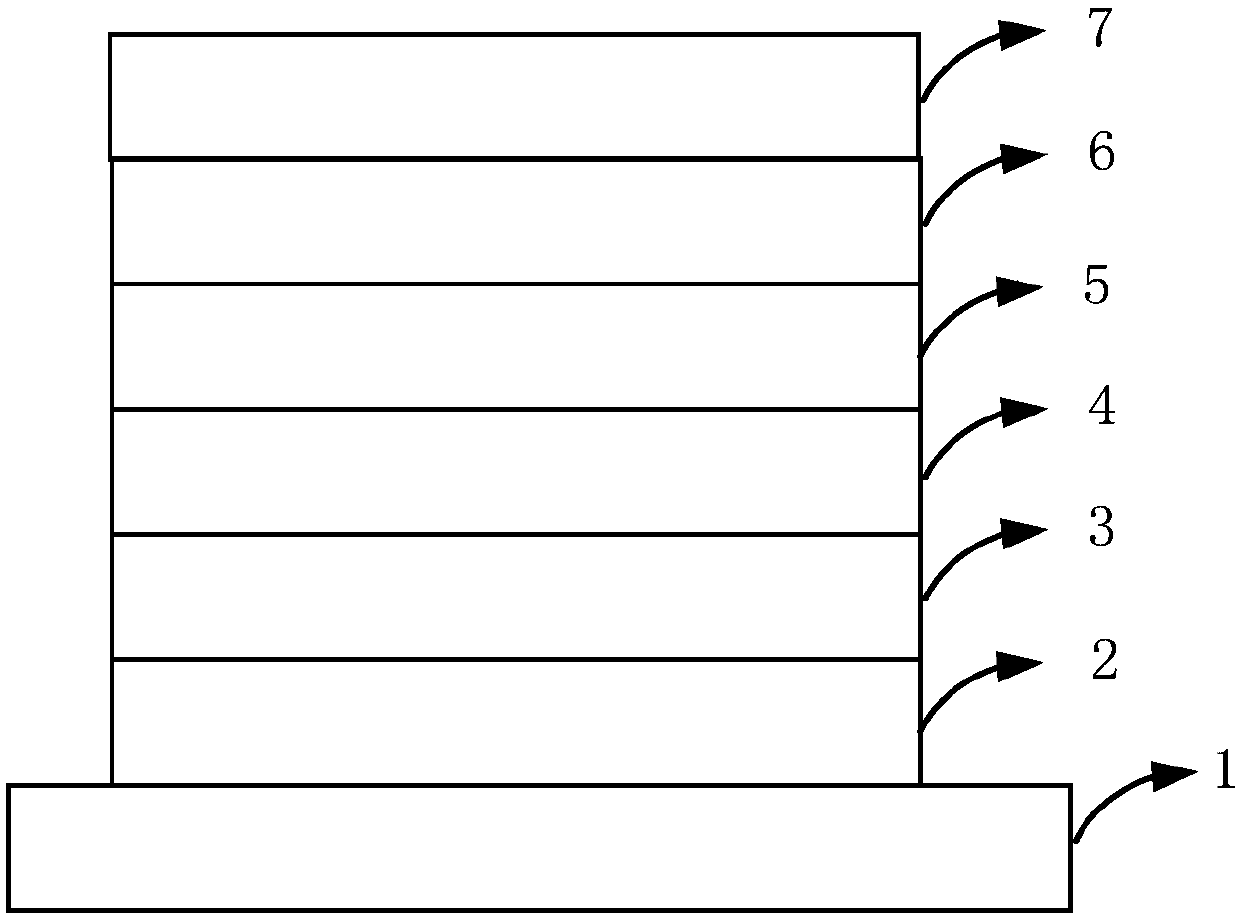

[0079] (1) First, place the patterned ITO substrate in acetone, lotion, deionized water, and isopropanol in order for ultrasonic cleaning, and each step of ultrasonic cleaning needs to last for about 15 minutes. After the ultrasound is completed, place the ITO in a clean oven to dry for later use.

[0080] (2) After the ITO substrate was dried, the ITO surface was treated with UV-ozone for 5 minutes to further remove the organic matter attached to the ITO surface and improve the work function of the ITO.

[0081] (3) Print a layer of PEDOT:PSS on the surface of the treated ITO substrate with a thickness of 30nm, and heat the substrate on a heating table at 150°C for 30 minutes to remove moisture. This step needs to be completed in air.

[0082] (4) Place the dried substrate coated with the hole injection layer in a nitrogen atmosphere, print a layer of hole transport layer material TFB, the thickness of this layer is 30nm, and then vacuumize under 10pa pressure for 30min to re...

Embodiment 2

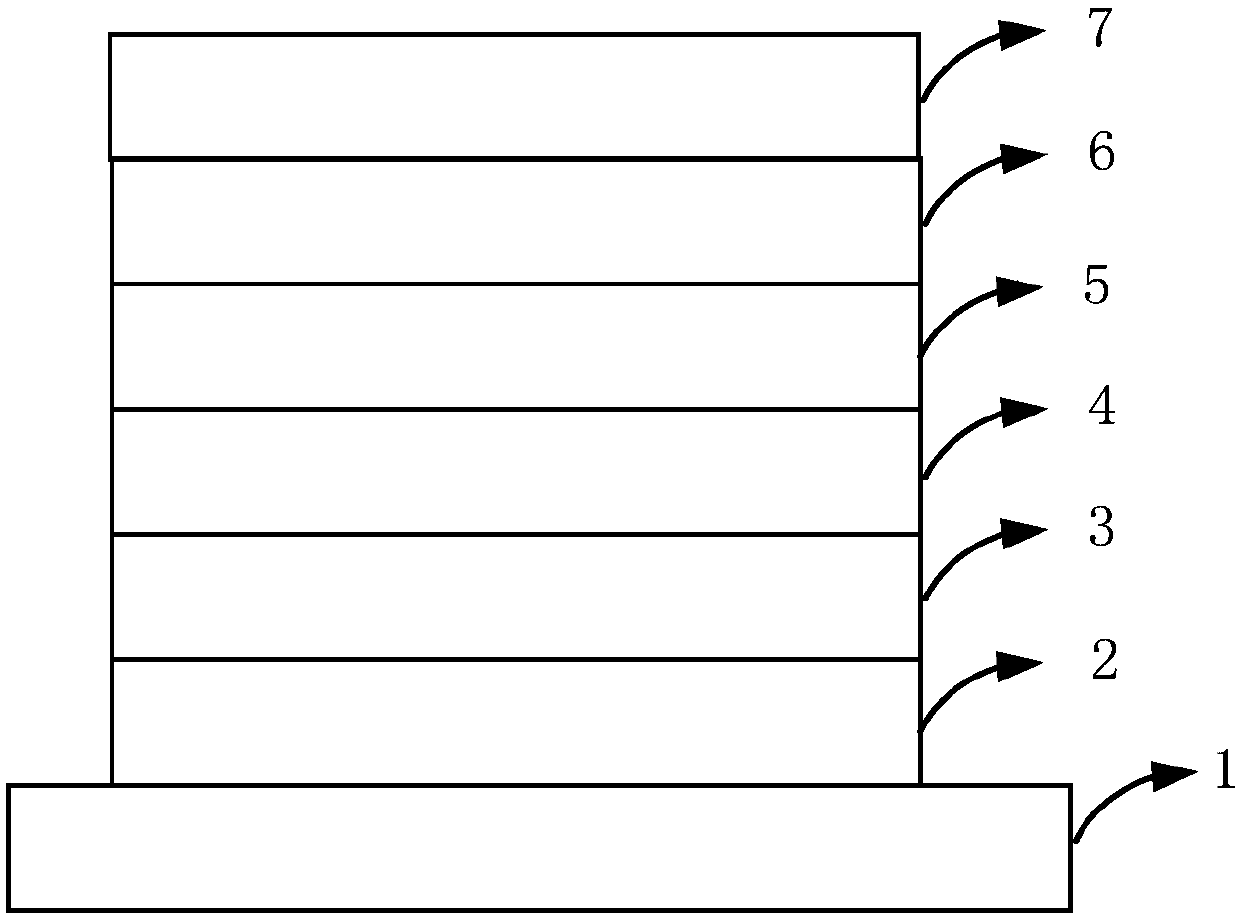

[0087] (1) Place the patterned ITO substrate in acetone, lotion, deionized water and isopropanol in sequence for ultrasonic cleaning, and each step of ultrasonic cleaning needs to last for about 15 minutes. After the ultrasound is completed, place the ITO in a clean oven to dry for later use.

[0088] (2) After the ITO substrate was dried, the ITO surface was treated with UV-ozone for 5 minutes to further remove the organic matter attached to the ITO surface and improve the work function of the ITO.

[0089] (3) Spin-coat a layer of PEDOT:PSS on the surface of the treated ITO substrate with a thickness of 30nm, and place the substrate on a heating table at 150°C for 30 minutes to remove moisture. This step needs to be completed in air.

[0090] (4) Place the dried substrate coated with the hole injection layer in a nitrogen atmosphere, spin coat a layer of hole transport layer material PVK, the thickness of this layer is 30nm, and place it on a heating stage at 150°C Heat for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com