A Stator Homopolar Hybrid Permanent Magnet Memory Motor

A hybrid permanent magnet and memory motor technology, applied in synchronous machines, synchronous machine parts, electromechanical devices, etc., can solve the problems of difficult implementation of the excitation current control system, increasing the complexity of electromagnetic characteristics, and easy mutual coupling, etc. Achieve the effect of easy heat dissipation and cooling, high space utilization, and widening operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

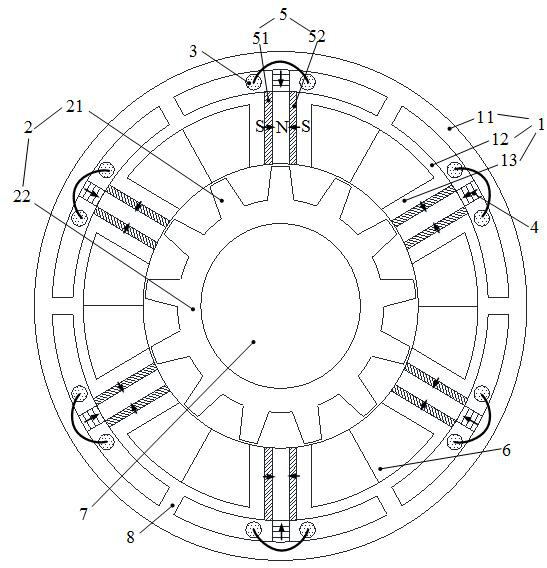

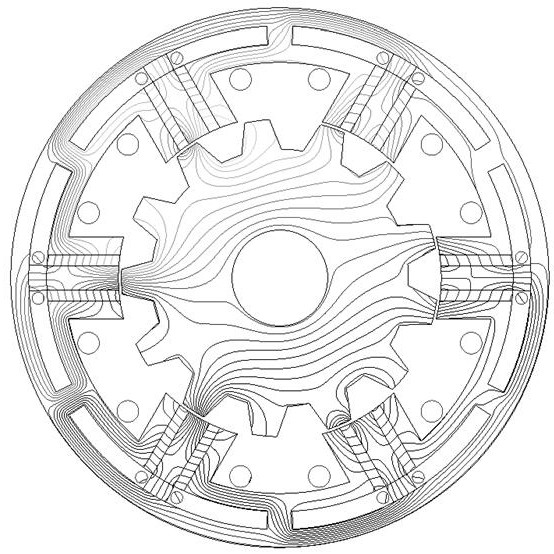

[0031] The technical scheme of the present invention is as follows: a stator homopolar hybrid permanent magnet memory motor, comprising a stator 1, a rotor 2 and a motor shaft 7, the stator 1 is arranged outside the rotor 2, the motor shaft 7 is located in the rotor 2, and the rotor 2 includes rotor teeth 21 and rotor core 22, the stator 1 includes an outer stator yoke 11, a middle stator core 12 and an inner stator tooth 13, and several Alnico permanent magnets 4, several Alnico permanent magnets 4 are distributed along the radial direction of the stator 1, and each Alnico permanent magnet 4 is wound with a charge and demagnetization winding 3; the stator teeth 13 are located at the Between the magnetic winding 3 and the rotor 2, two parallel NdFeB permanent magnets 5 are arranged in the stator teeth 13, one end of the NdFeB permanent magnet 5 faces the rotor 2, and the other end faces the charging and demagnetizing winding 3 and AlNiCo In the area between the permanent magne...

Embodiment 2

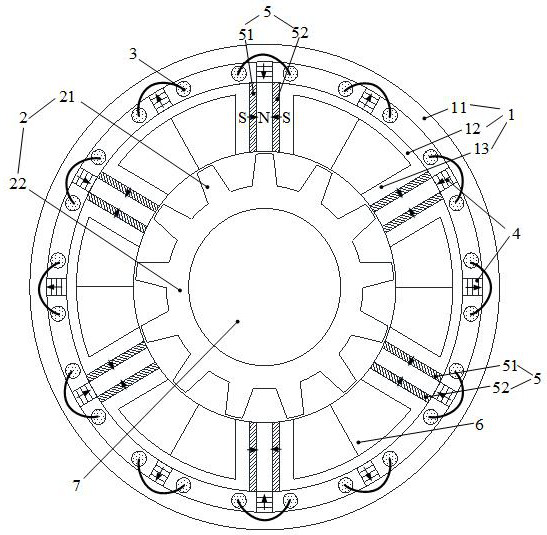

[0035] The technical scheme of the present invention is as follows: a stator homopolar hybrid permanent magnet memory motor, comprising a stator 1, a rotor 2 and a motor shaft 7, the stator 1 is arranged outside the rotor 2, the motor shaft 7 is located in the rotor 2, and the rotor 2 includes rotor teeth 21 and rotor core 22, the stator 1 includes an outer stator yoke 11, a middle stator core 12 and an inner stator tooth 13, and several Alnico permanent magnets 4, several Alnico permanent magnets 4 are distributed along the radial direction of the stator 1, and each Alnico permanent magnet 4 is wound with a charge and demagnetization winding 3; the stator teeth 13 are located at the Between the magnetic winding 3 and the rotor 2, wherein the number of charging and demagnetizing windings 3 is twice the number of stator teeth 13, every other charging and demagnetizing winding 3 is provided with a stator tooth 13, and two stator teeth 13 are arranged inside Parallel NdFeB perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com