Novel residue-free closed-type feeding device for breeding

A feeding device and closed technology, which is applied in the field of a new type of closed breeding feeding device without leftovers, can solve the problems of immunity and treatment troubles and work, loss of farmers, and moldy feed that cannot be eaten up, so as to avoid respiratory problems. Effects of diseases, reduction of parasites, avoidance of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

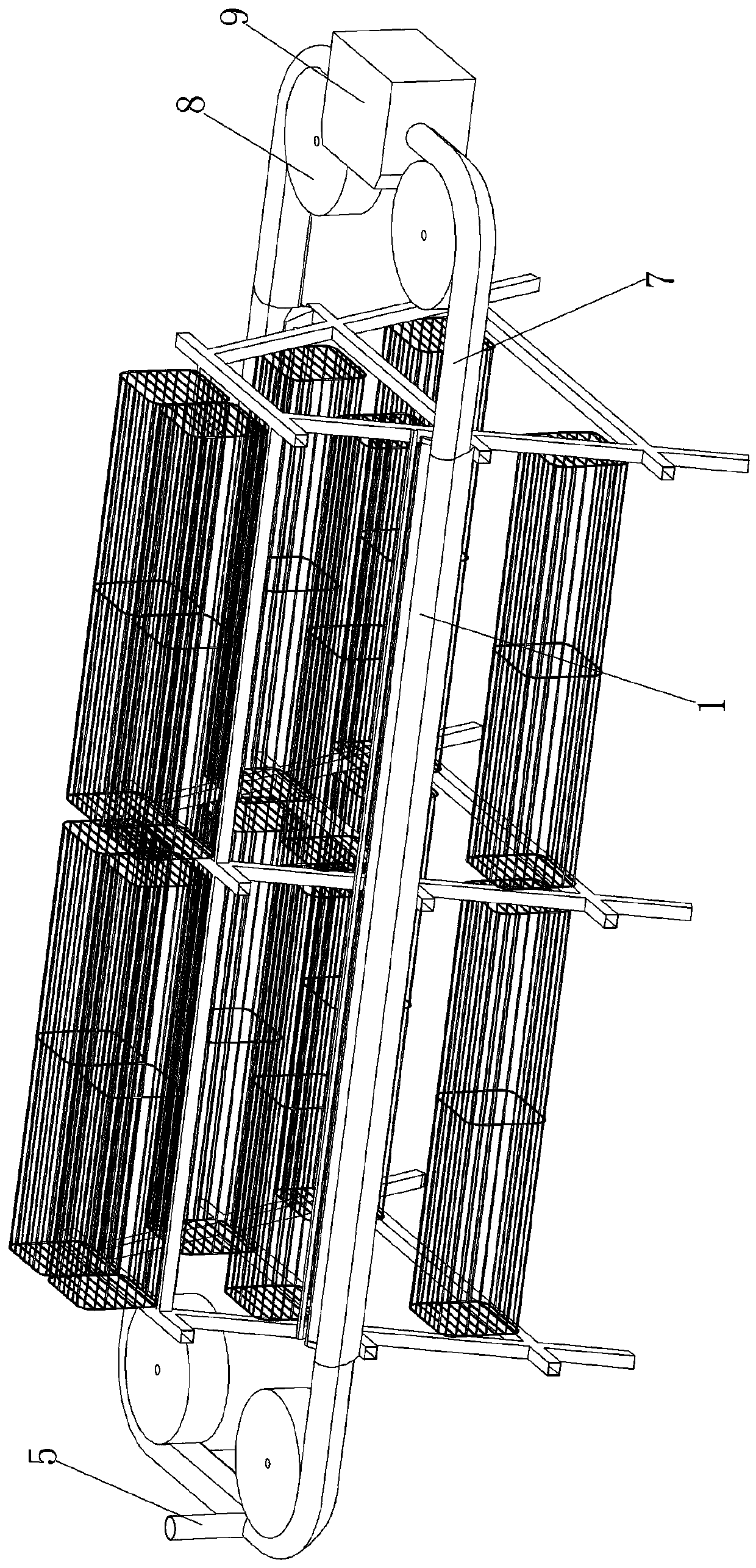

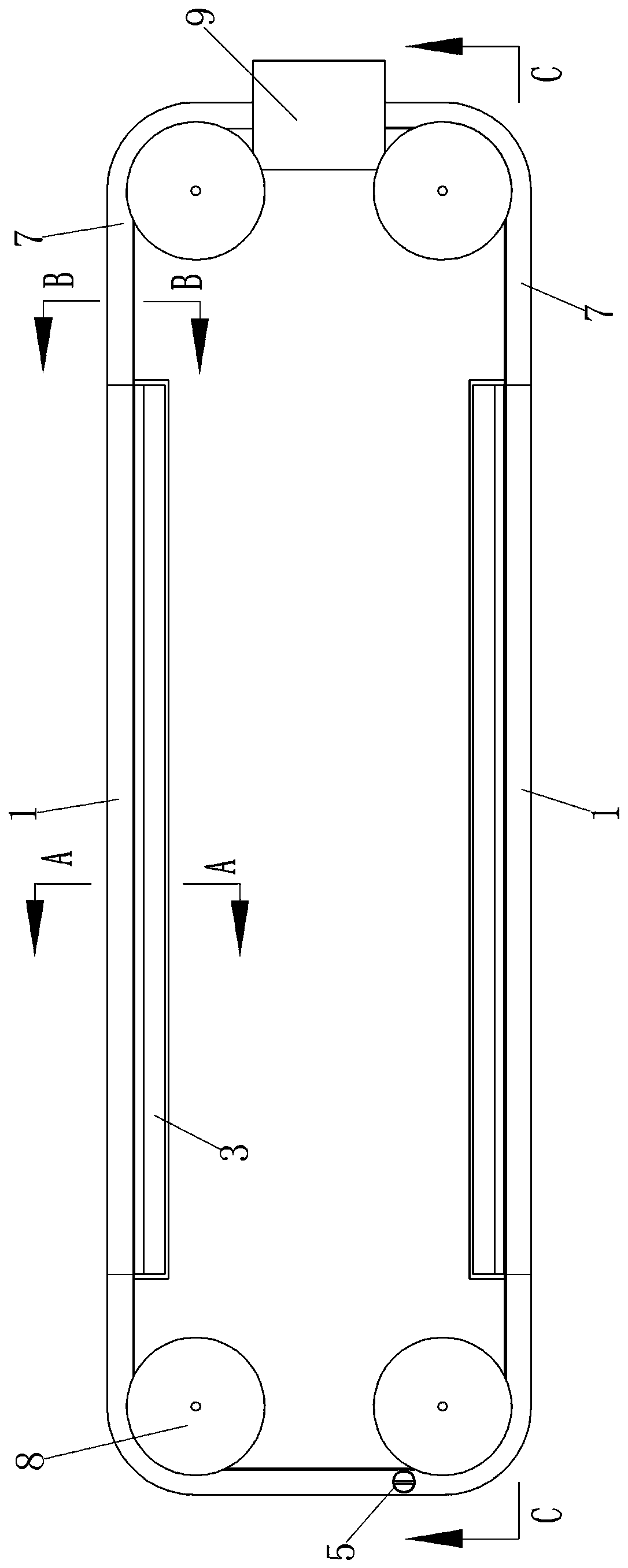

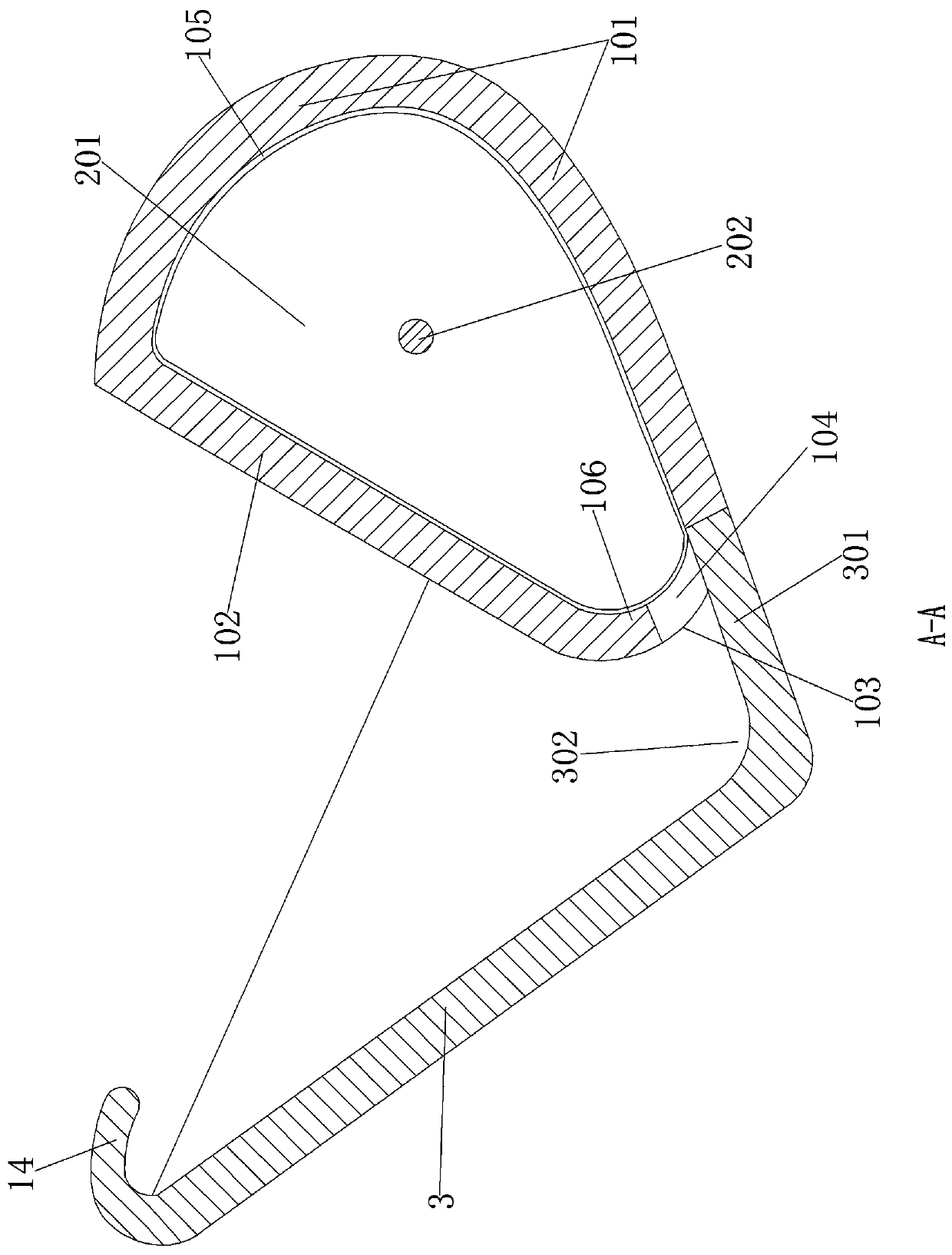

[0034] Embodiment 1, refer to the accompanying drawings (1-6) of the specification, a new type of feeding device for closed farming without leftovers, including feeding feed conveying pipes, stopper chains, and feeding troughs, characterized in that: the feeding The feed conveying pipe is a section of pipe with a lower end provided with a feeding opening. The outer side of the feeding feed conveying pipe is an outer pipe body with an arc-shaped section, and the inner side is a section of inclined long plate-shaped inner pipe body. The lower end of the pipe body A and the outer pipe body is connected with an arc-shaped sealing plate to seal the feeding material conveying pipe into a feeding chamber. The lower part of the arc-shaped sealing plate is evenly distributed with a number of the above-mentioned feeding port A, and the inner pipe body The lower end of A and the position corresponding to the feeding port A are provided with an arc-shaped baffle that penetrates into the fe...

Embodiment 2

[0039] Embodiment two: see Figure 1-2 , 5-7, the second embodiment is basically the same as the first embodiment, and the similarities will not be described in detail. The difference is that the outside of the feeding feed delivery pipe described in this embodiment is a section of outer pipe body B with a superior arc in cross section. , the inner port of the outer tube body B is vertically provided with an inner tube body B in the shape of a long plate, and the outer tube body A of the embodiment 1 is replaced with the outer tube body B, and the embodiment is replaced with the inner tube body B The inner tube body A of one; the junction of the inner tube body B and the outer tube body B is evenly provided with several discharge openings B, and the upper edge of the short side wall of the trough is connected with the lower bottom of the outer tube body A. Ends are connected, and the feeding opening B is positioned at the top of the short side wall of the feeding trough, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com