Environmental barrier-infrared stealth integrated coating, composite material containing coating and preparation method of composite material

A composite material and environmental barrier technology, applied in the field of coated composite materials and their preparation, and composite coatings, can solve problems such as difficulty in meeting the long-life requirements of thermal structural materials, lack of infrared stealth function, and material performance degradation, etc., to achieve Excellent infrared stealth function, reduce the intensity of infrared radiation, improve the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

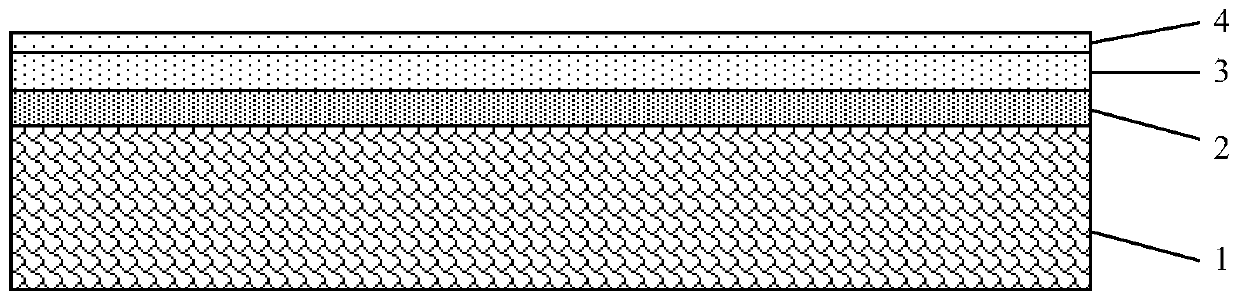

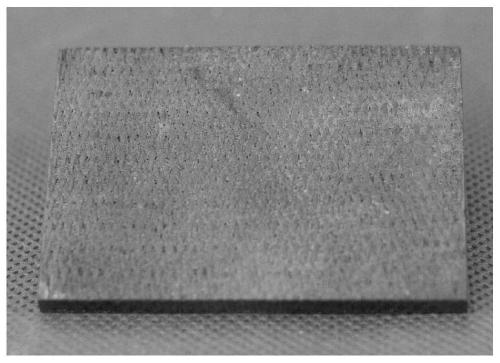

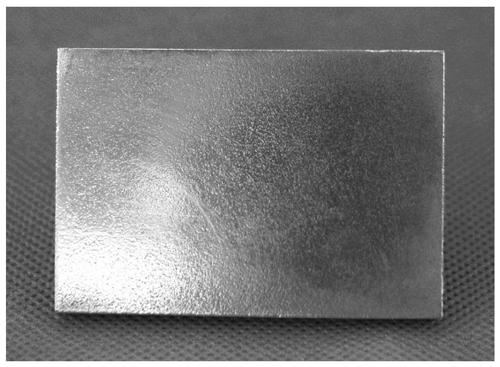

[0051] a kind of like figure 1 The structure shown is coated on the SiC / SiC composite substrate 1 (such as figure 2 Shown) the environmental barrier-infrared stealth integrated coating on the surface, the environmental barrier-infrared stealth integrated coating is a multi-layer superimposed structure, including silicon bonding layer 2, mullite / BSAS (0.5BaO· 0.5SrO Al 2 o 3 2SiO2 2 ) Composite anti-oxidation layer 3, and Bi containing AgPd alloy filler 2 o 3 -ZnO-based glass with low infrared emissivity / sealing layer 4. The thickness of the silicon bonding layer 2 is about 75 μm, the thickness of the mullite layer is about 75 μm, the thickness of the BSAS layer is about 75 μm, and the thickness of the low infrared emissivity / sealing layer 4 is about 20 μm. Bi in AgPd-containing alloy 2 o 3 - ZnO-based glass with low infrared emissivity / sealing layer 4, the mass ratio of glass phase, metal Ag, and metal Pd is 8:64:28. Bi 2 o 3 The mass percentages of the raw materia...

Embodiment 2

[0064] An environmental barrier-infrared stealth integrated coating that can be coated on the surface of a SiC / SiC composite material substrate 1, the environmental barrier-infrared stealth integrated coating is a multi-layer superimposed structure, including a silicon bonding layer from the inside to the outside 2. Mullite / BSAS (0.5BaO 0.5SrO Al 2 o 3 2SiO2 2 ) Composite anti-oxidation layer 3, and Bi containing AgPd alloy filler 2 o 3 -ZnO-based glass with low infrared emissivity / sealing layer 4. The thickness of the silicon bonding layer 2 is about 75 μm, the thickness of the mullite layer is about 75 μm, the thickness of the BSAS layer is about 75 μm, and the thickness of the low infrared emissivity / sealing layer 4 is about 20 μm. Bi in AgPd-containing alloy 2 o 3 - ZnO-based glass with low infrared emissivity / sealing layer 4, the mass ratio of glass phase, metal Ag, and metal Pd is 8:64:28. Bi 2 o 3 The mass percentages of the raw materials of each component in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com