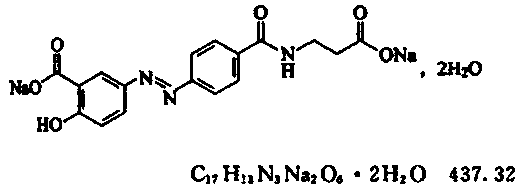

Preparing method of balsalazide sodium

A technology of balsalazide sodium and balsalazide, which is applied in the field of medicine, can solve the problems that balsalazide sodium does not meet the standards of the United States Pharmacopoeia, and achieve the effects of stable process, high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Refining of balsalic acid: Add 100g of crude balsalic acid and 150g of dimethylformamide into a 500ml three-neck round bottom flask, heat to 85°C and stir until the crude balsalic acid is completely dissolved, then add 3g of activated carbon Decolorize for 1 hour, filter with suction; add the filtrate to a 1000ml three-necked round bottom flask, heat to 75°C, add 400g of ethanol, slowly cool down to 30°C, keep warm for 3 hours, continue to cool to 15°C and filter with suction, wash with ethanol, and dry Obtained 91.5g of balsalazide refined product, the purity was 99.4% detected by the USP related substance method, and the largest single impurity was 0.18%.

[0021] (2) Preparation of balsalazide sodium: Add 100g of refined balsalazide and 300g of dimethylformamide into a 500ml three-necked round-bottomed flask, heat to 40°C and stir to completely dissolve the refined balsalazide. Slowly add 25% (W / W) sodium hydroxide solution dropwise at temperature, control the pH...

Embodiment 2

[0023] (1) Refining of balsalic acid: Add 100g of crude balsalic acid and 200g of dimethyl sulfoxide into a 500ml three-neck round bottom flask, heat to 80°C and stir until the crude balsalic acid is completely dissolved, then add 3g of activated carbon Decolorize for 1 hour, filter; add the filtrate to a 2000ml three-neck round bottom flask, heat to 70°C, add 500g of ethanol, slowly cool down to 35°C, keep warm for crystallization for 4 hours, continue cooling to 15°C for suction filtration, wash with ethanol, and dry to obtain 89.1g of balsalazide refined product, with a purity of 99.6% detected by the USP related substance method, and the largest single impurity is 0.12%.

[0024] (2) Preparation of balsalazide sodium: Add 100g of refined balsalazide and 200g of dimethyl sulfoxide into a 500ml three-neck round bottom flask, heat to 50°C and stir to completely dissolve the refined balsalazide. Slowly add 30% (W / W) sodium hydroxide solution dropwise at temperature, control th...

Embodiment 3

[0026] (1) Refining of balsalic acid: Add 100g of crude balsalic acid and 350g of dimethylformamide into a 500ml three-neck round bottom flask, heat to 80°C and stir until the crude balsalic acid is completely dissolved, then add 3g of activated carbon Decolorize for 1 hour, filter; add the filtrate to a 2000ml three-neck round bottom flask, heat to 78°C, add 600g of ethanol, slowly cool down to 40°C, keep warm for crystallization for 4.5 hours, continue cooling to 17°C for suction filtration, wash with ethanol, and dry to obtain 90.7g refined product of balsalazide, the purity of which is 99.5% by USP related substance method, and the largest single impurity is 0.10%.

[0027] (2) Preparation of balsalazide sodium: Add 100g of refined balsalazide and 400g of dimethyl sulfoxide into a 1000ml three-neck round-bottomed flask, heat to 60°C and stir to completely dissolve the refined balsalazide. Slowly add 35% (W / W) sodium hydroxide solution dropwise at high temperature, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com