Method and device for preparing acrylonitrile by recycling HPPO process waste gas

A technology of acrylonitrile and resource utilization, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid nitrile, etc., can solve the problems of large nitrogen consumption and insufficient economy, achieve high safety and reduce VOC emissions , solve the effect of large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

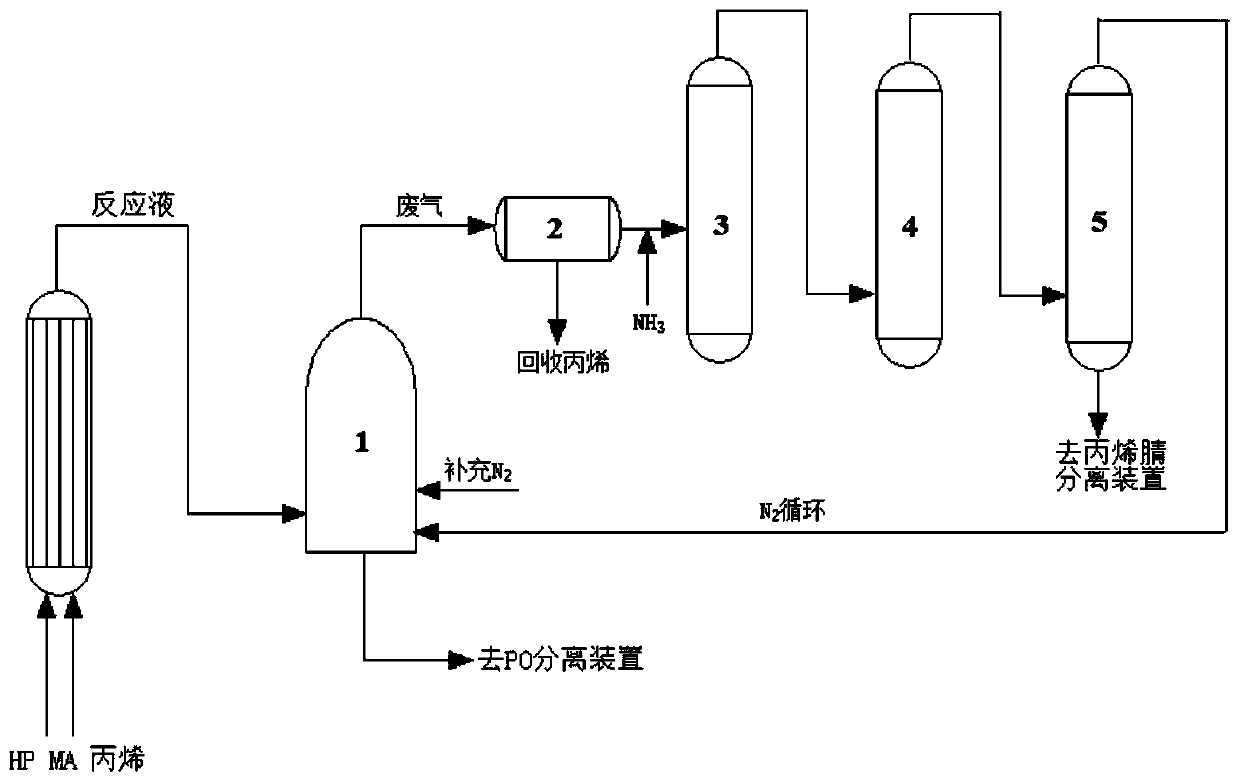

Image

Examples

Embodiment 1

[0031] In the gas phase discharged from the top of the deoxidation tower in the HPPO process, the content of propylene in the gas phase is 1.22%, the content of methanol is 0.84%, the content of water is 0.27%, the content of propylene oxide is 0.15%, the content of oxygen is 0.51%, and the content of nitrogen is 96.71%. ℃ condensing tank, stay for 2s, condense and recover the high-boiling organic matter in it, analyze the composition of the waste gas discharged from the condensing tank online, the content of propylene in the waste gas is 0.56%, the content of methanol is 40ppm, the content of water is 70ppm, the content of propylene oxide is 25ppm, and the content of oxygen is 0.52%. The nitrogen content is 98.91%. Then add ammonia gas to the waste gas discharged from the condensation tank according to the molar ratio of propylene and ammonia gas equal to 1:1, and then pass it into the acrylonitrile reactor equipped with bismuth phosphotungstate catalyst, the reaction pressure...

Embodiment 2

[0033] In the gas phase discharged from the top of the deoxidation tower in the HPPO process, the content of propylene in the gas phase is 0.86%, the content of methanol is 1.84%, the content of water is 0.89%, the content of propylene oxide is 0.05%, the content of oxygen is 1.01%, and the content of nitrogen is 95.35%. 5°C condensing tank, stay for 8s, condense and recover the high boiling point organic matter, analyze the composition of the waste gas discharged from the condensing tank online, the content of propylene in the waste gas is 0.36%, the content of methanol is 80ppm, the content of water is 55ppm, the content of propylene oxide is 15ppm, and the content of oxygen is 1.04%. , Nitrogen content 98.59%. Then add ammonia gas to the waste gas discharged from the condensation tank according to the molar ratio of propylene and ammonia gas equal to 1:1.1, and pass it into the acrylonitrile reactor equipped with bismuth oxide catalyst, the reaction pressure is 0.5MPa, the r...

Embodiment 3

[0035]In the gas phase discharged from the top of the deoxidation tower in the HPPO process, the content of propylene in the gas phase is 1.86%, the content of methanol is 1.38%, the content of water is 0.97%, the content of propylene oxide is 0.34%, the content of oxygen is 1.91%, and the content of nitrogen is 93.54%. 10°C condensation tank, stay for 10s, condense and recover the high boiling point organic matter, analyze the composition of the waste gas discharged from the condensation tank online, the content of propylene in the waste gas is 0.96%, the content of methanol is 90ppm, the content of water is 65ppm, the content of propylene oxide is 35ppm, and the content of oxygen is 1.94%. , Nitrogen content 97.10%. Then add ammonia gas to the waste gas discharged from the condensation tank according to the molar ratio of propylene and ammonia gas equal to 1:1.2, and pass it into the acrylonitrile reactor equipped with bismuth oxide-tin oxide catalyst, the reaction pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com