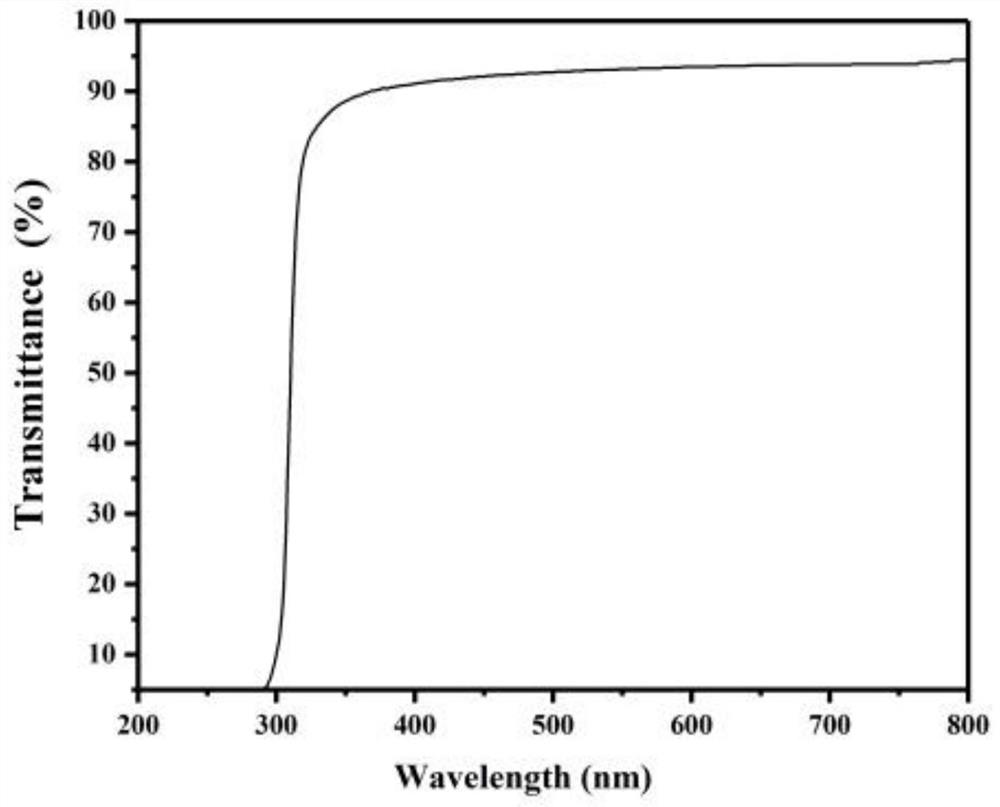

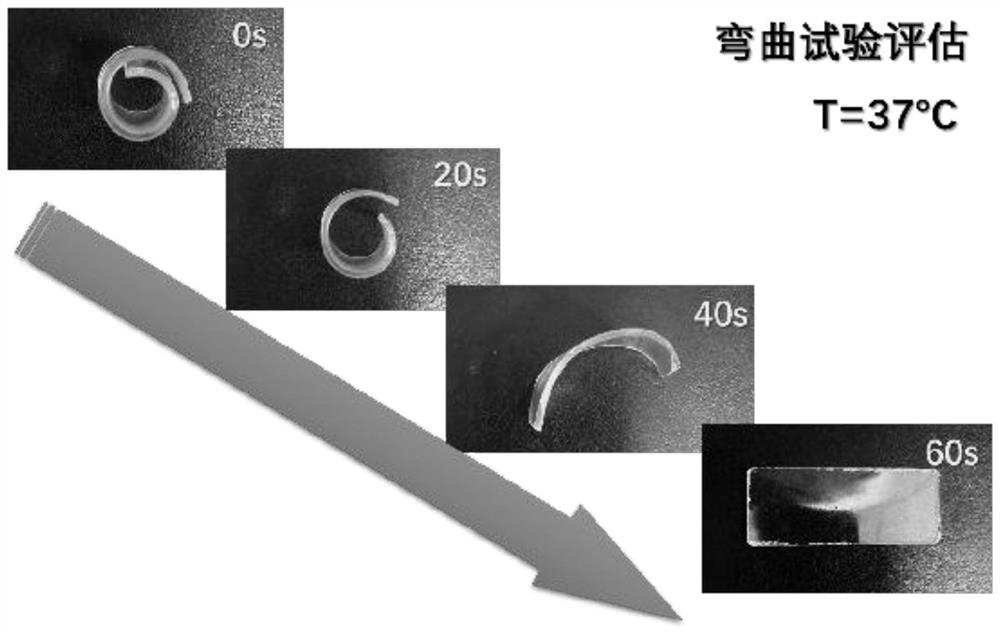

A kind of high refractive index hydrophobic foldable intraocular lens material and its preparation method

A technology of intraocular lens and high refractive index, which is applied in the fields of prosthesis, tissue regeneration, medical science, etc., can solve the problems of unstable homogeneity of polymer materials, the optical performance needs to be improved, and it is difficult to recover completely, so as to reduce the cost of implant surgery. Risk and cost, ease of industrial production, and the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Select and weigh monomers: in the first part B monomers, B1 is 2-phenoxyethyl methacrylate, accounting for 55% of the total monomer mass, and B2 is 2-phenoxyethyl acrylate, accounting for 35% of the total monomer mass; the second part C monomer is 2-ethylhexyl methacrylate, accounting for 8% of the total monomer mass; the third part crosslinking agent D is ethylene glycol dimethacrylate Esters account for 2% of the total monomer mass (B+C+D=100%); the initiator is (2-ethylhexyl) tert-butyl peroxide, and the initiator accounts for 2% of the total reactant mass.

[0031] Add each part of the monomer and initiator that has been weighed into a polytetrafluoroethylene beaker and mix thoroughly, then quantitatively move into a specific polytetrafluoroethylene mold (the aspect ratio is 10:4:1), and add to the mixed solution Nitrogen was introduced into the mold for 20 minutes, the mold was placed in a vacuum oven and then heated to 80°C, and the temperature was kept constant f...

Embodiment 2

[0034] Select and weigh the monomers: in the first part B monomers, B1 is 2-phenoxyethyl methacrylate, accounting for 60% of the total monomer mass, and B2 is 2-phenoxyethyl acrylate, accounting for 36% of the total monomer mass; the second part C monomer is 2-ethylhexyl methacrylate, accounting for 2% of the total monomer mass; the third part crosslinking agent D is ethylene glycol dimethacrylate The ester accounts for 2% of the total monomer mass (B+C+D=100%); the initiator is (2-ethylhexyl) tert-butyl peroxide, which accounts for 2% of the total reactant mass.

[0035] Add each part of the monomer and initiator that has been weighed into the polytetrafluoroethylene beaker in turn and mix thoroughly, then quantitatively transfer it into a specific polytetrafluoroethylene mold, pass nitrogen into the mixed solution for 20 minutes, and place the mold in a vacuum After filling the oven with vacuum, heat it to 80°C, keep the temperature constant for a pre-reaction for 2 hours, t...

Embodiment 3

[0038] Select and weigh the monomers: in the first part B monomers, B1 is 2-phenoxyethyl acrylate, accounting for 60% of the total monomer mass, and B2 is 2-ethylhexyl methacrylate, accounting for the total 36% of the monomer mass; the second part C monomer is methacrylate-3,5,5-trimethylhexyl ester, accounting for 2% of the total monomer mass; the third part crosslinking agent D is the molecular weight of 1000 Polyethylene glycol dimethacrylate accounts for 2% of the total monomer mass; the initiator is (2-ethylhexyl) tert-butyl peroxide, which accounts for 2% of the total reactant mass.

[0039] Add each part of the monomer and initiator that has been weighed into the polytetrafluoroethylene beaker in turn and mix thoroughly, then quantitatively transfer it into a specific polytetrafluoroethylene mold, pass nitrogen into the mixed solution for 20 minutes, and place the mold in a vacuum After filling the oven with vacuum, heat it to 90°C, keep the temperature constant for a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com