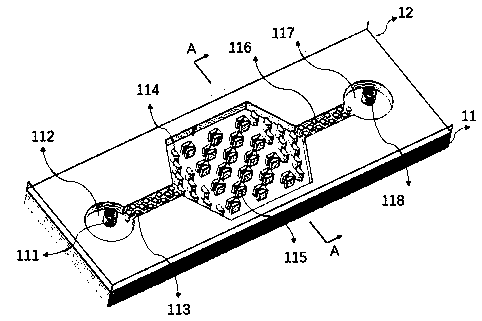

Micro-fluidic chip for capturing single cells

A microfluidic chip and single-cell technology, applied in the field of microfluidics, can solve the problem of not achieving single-cell level capture, and achieve the effect of simple structure, flexible combination, and good function realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0074] In the following examples 1-3:

[0075] 1. The preparation process of the single cell capture microfluidic chip is as follows:

[0076] (1) Silicon wafer cleaning: standard silicon wafer cleaning, placed on a 200°C electric heating plate for 15 minutes, and dried;

[0077] (2) Silicon wafer modification: place the silicon wafer in a volatilization tank, drop 1 to 2 drops of modification reagent HMDS (Hexamethyldisilazane), and volatilize for ≥ 3 minutes;

[0078] (3) Silicon wafer rejection: pour the photoresist on the processed silicon wafer, set the speed of rejection according to the required pattern depth or height, and let it stand for 1 to 2 minutes after uniform glue;

[0079] (4) Silicon wafer exposure: pre-baking process sets the pre-baking time by determining the properties of the photoresist used; the exposure process needs to consider the power of the exposure machine and the metering required for the material to set the exposure time; after exposure, deter...

Embodiment 1

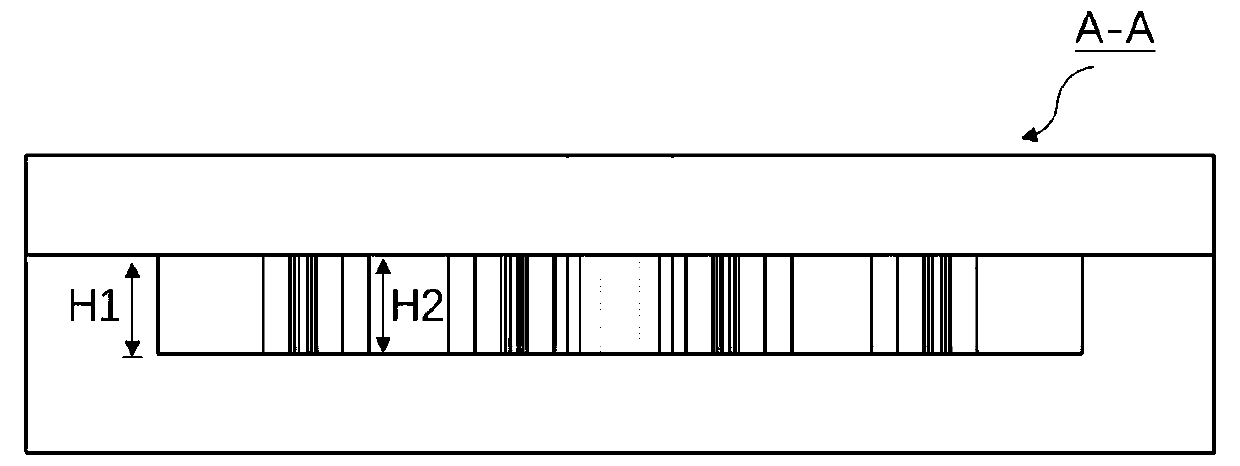

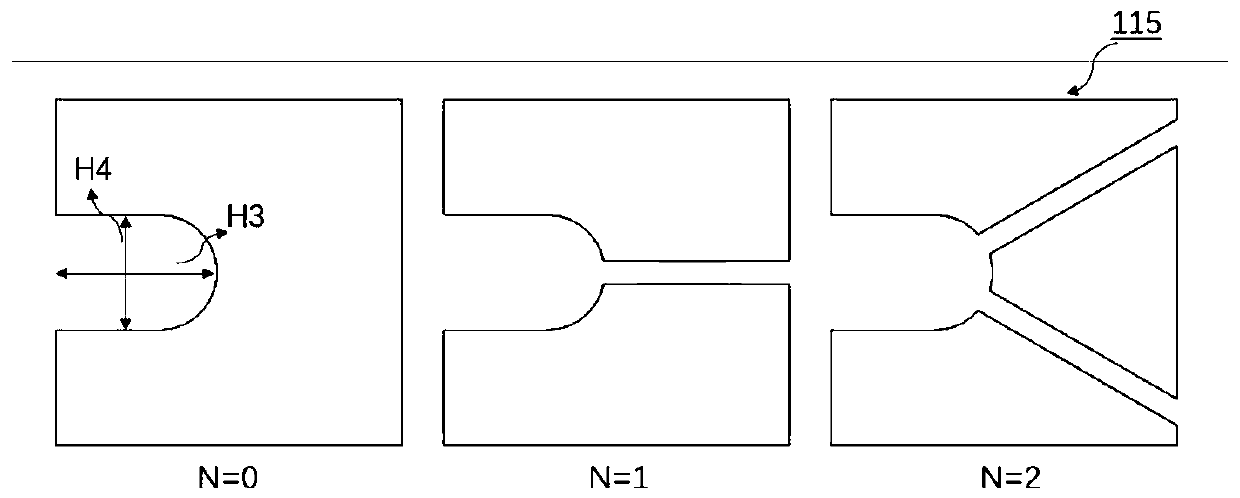

[0095] Prepare a microfluidic chip in the above way (the following microfluidic chips are referred to as chips for short), wherein the size parameters and other parameters are: H1=H2=20 μm, H3=16 μm, H4=16 μm, H5=5 μm, N=0 . The chip was washed with deionized water and phosphate buffered saline (PBS) successively with a syringe pump. Pass the cell carrier fluid into the chip, control the injection speed to 0.1 μl / s, place the chip under a microscope for observation, and finally realize the capture of single cells in the trap. Through Embodiment 1 of the present invention, the capture efficiency of single cells in the trap array reaches 96%, and the single sample consumption is effectively reduced by more than 90% compared with the same concentration of cell culture dishes.

Embodiment 2

[0097] The microfluidic chip was prepared in the above manner, wherein the size parameters and other parameters were: H1=H2=20 μm, H3=16 μm, H4=16 μm, H5=5 μm, N=1. The chip was washed with deionized water and phosphate buffered saline (PBS) successively with a syringe pump. Pass the cell carrier fluid into the chip, control the injection speed to 0.2 μl / s, place the chip under a microscope for observation, and finally realize the capture of single cells in the trap. Through Embodiment 2 of the present invention, the capture efficiency of single cells in the trap array reaches 96%, and the single sample consumption is effectively reduced by more than 95% compared with the same concentration of cell culture dishes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com