Preparation method of molybdenum target material

A molybdenum target and rolling direction technology, which is applied in the field of sputtering target preparation, can solve problems such as insufficient purity, uneven texture distribution, and affecting the sputtering performance of molybdenum sputtering targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

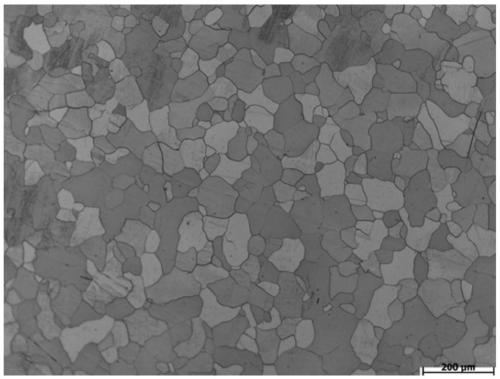

Image

Examples

Embodiment 1

[0022] The preparation method of the molybdenum target material of the present embodiment comprises the following steps:

[0023] (1) The molybdenum powder raw material with a purity of 99.95%, a particle size of 2 μm, uniform particle size, normal distribution, good dispersibility, and no obvious agglomeration phenomenon is first charged, and then cold isostatically pressed for 15 minutes under a pressing pressure of 180 MPa to obtain molybdenum Plate green body, molybdenum plate green body was sintered by medium frequency induction under hydrogen atmosphere for 8 hours, and the sintering temperature was 1800°C, and finally a cylindrical sintered molybdenum billet was obtained;

[0024] (2) further purifying the sintered molybdenum blank obtained in step (1) by electron beam smelting to obtain the purified molybdenum blank, and its purity is 99.99%;

[0025] (3) The molybdenum billet purified in step (2) is first forged and opened, and then press-processed in a circumferentia...

Embodiment 2

[0029] The preparation method of the molybdenum target material of the present embodiment comprises the following steps:

[0030] (1) The molybdenum powder raw material with a purity of 99.97%, a particle size of 3 μm, uniform particle size, normal distribution, good dispersibility, and no obvious agglomeration is first charged, and then cold isostatically pressed for 13 minutes under a pressing pressure of 185 MPa to obtain molybdenum Plate green body, the molybdenum plate green body was sintered by medium frequency induction in a hydrogen atmosphere for 7 hours, and the sintering temperature was 1820°C, and finally a cylindrical sintered molybdenum billet was obtained;

[0031] (2) further purifying the sintered molybdenum blank obtained in step (1) by electron beam smelting to obtain the purified molybdenum blank, and its purity is 99.996%;

[0032] (3) The molybdenum billet purified in step (2) is first forged and opened, and then press-processed in a circumferential rolli...

Embodiment 3

[0036] The preparation method of the molybdenum target material of the present embodiment comprises the following steps:

[0037] (1) The molybdenum powder raw material with a purity of 99.99%, a particle size of 3 μm, a uniform particle size, a normal distribution, good dispersion, and no obvious agglomeration is first charged, and then cold isostatically pressed for 10 minutes under a pressing pressure of 200 MPa to obtain molybdenum Plate green body, the molybdenum plate green body was sintered by medium frequency induction in a hydrogen atmosphere for 6 hours, and the sintering temperature was 1850°C, and finally a cylindrical sintered molybdenum billet was obtained;

[0038] (2) further purifying the sintered molybdenum blank obtained in step (1) by electron beam smelting to obtain the purified molybdenum blank, and its purity is 99.999%;

[0039] (3) The molybdenum billet purified in step (2) is first forged and opened, and then press-processed in a circumferential rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com