Chargeable and dischargeable aqueous aluminum ion battery and preparation process thereof

An aluminum ion battery, charging and discharging technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex structure and impracticality, and achieve good conductivity, excellent chemical stability, and low pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

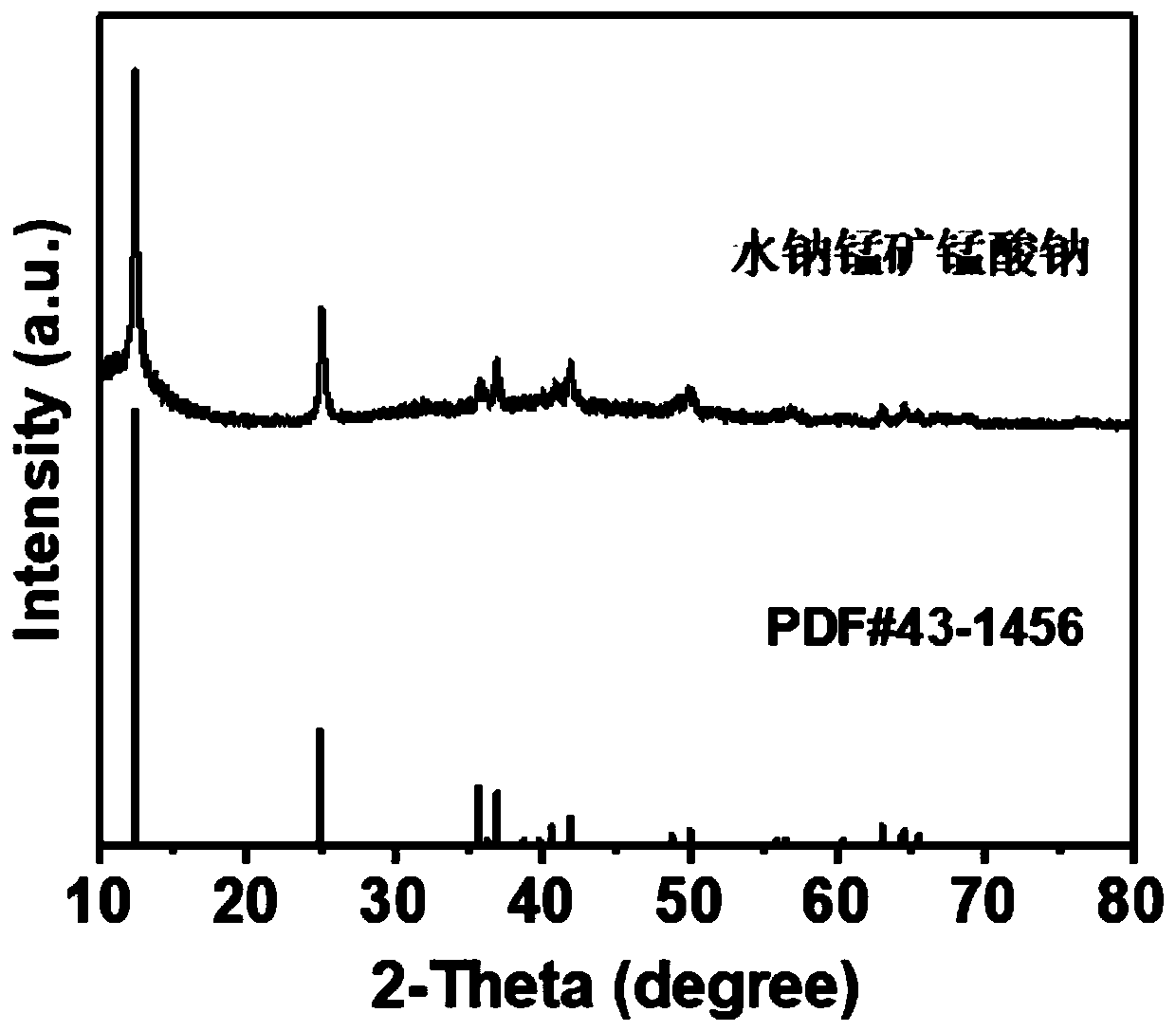

[0023] Preparation of battery positive electrode: 0.3M Mn(NO 3 ) 2 The solution was added to 0.6M NaOH and 2M H 2 o 2 solution, after stirring for 0.5h, add 2M NaOH, put the mixture into the reaction kettle, and react at 150°C for 16h to obtain the Na of birnessite 0.55 mn 2 o 4 1.5H 2 O. Mix this birnessite sodium manganate material with Super P conductive agent and polyvinylidene fluoride (PVDF) binder in N-methylpyrrolidone at a mass ratio of 70:20:10 to make a slurry, and coat it on stainless steel On the sheet, dry in a vacuum oven for 10h to make an electrode sheet.

[0024] Electrolyte preparation: Weigh 0.95 g of aluminum trifluoromethanesulfonate powder in a glove box and place it in a reagent bottle, add 1 mL of deionized water, stir for 12 hours, and prepare a 2M aluminum trifluoromethanesulfonate electrolyte.

[0025] Preparation of aluminum negative electrode: mix aluminum chloride and ionic liquid according to the preferred molar ratio of 1.3:1, and let s...

Embodiment 2

[0028] Others are as in Example 1.

[0029] Metal aluminum is directly used as the negative electrode of the battery without immersion in ionic liquid.

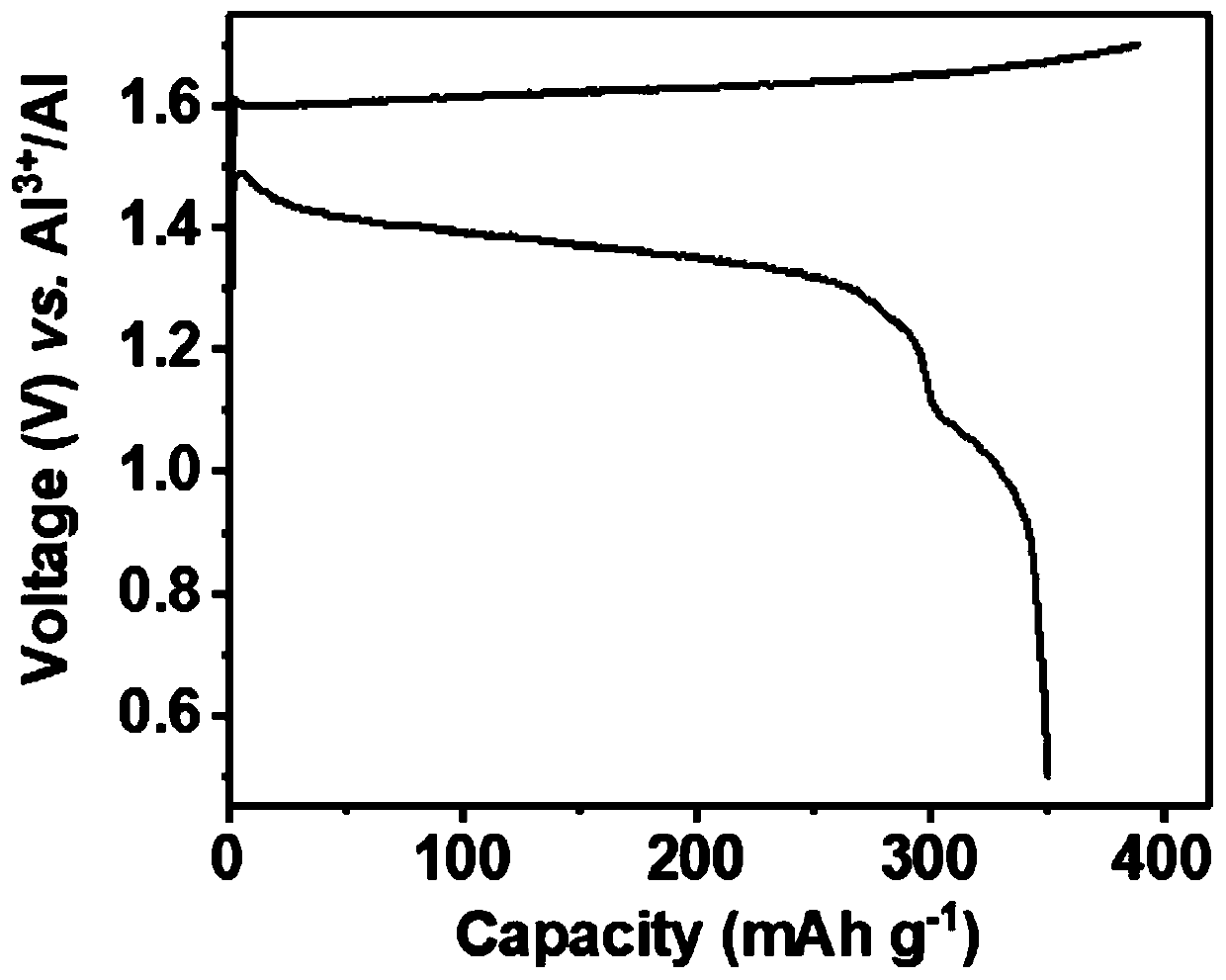

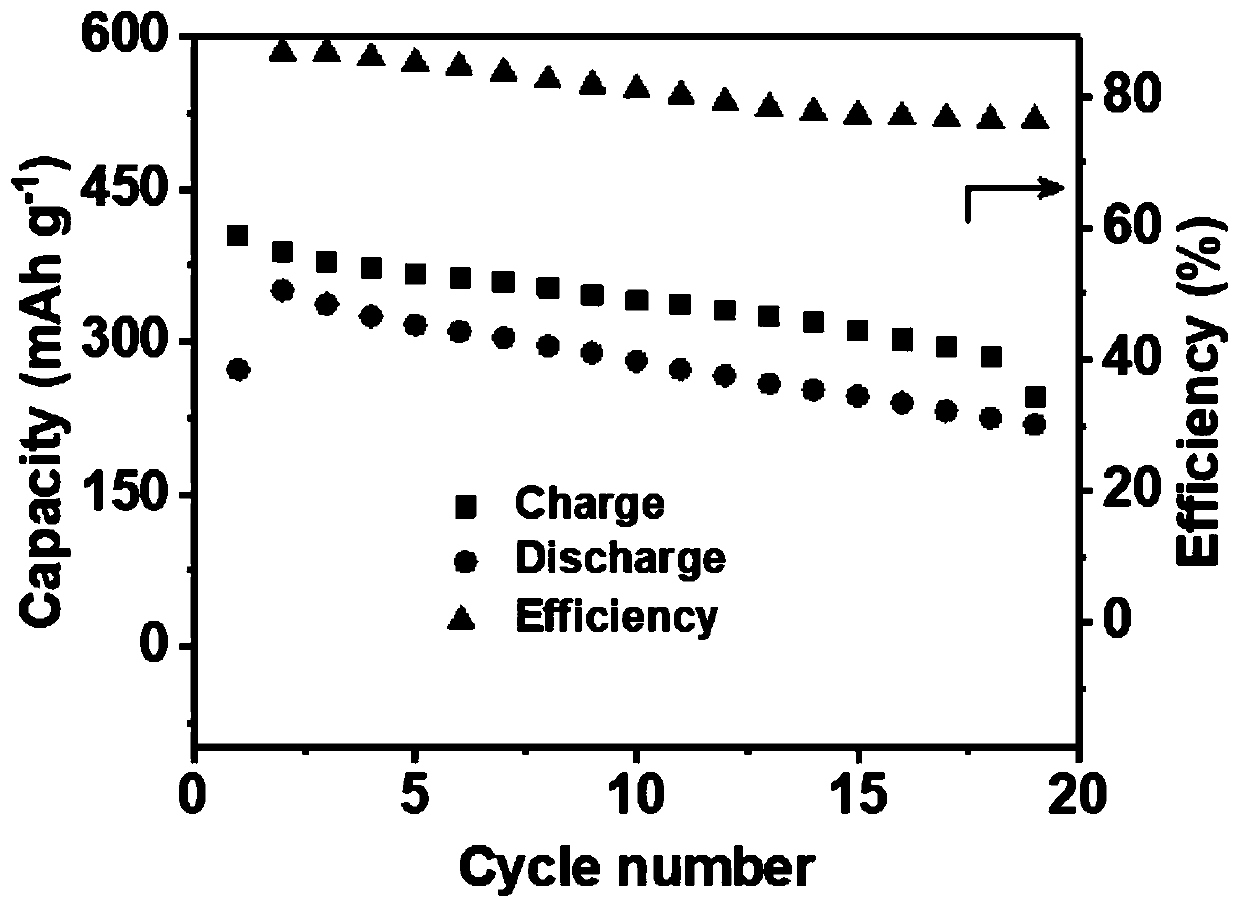

[0030] Battery at 50mAg -1 Charge and discharge at constant current, the charge and discharge voltage range is 0.5–1.8V, and the discharge specific capacity is 365mAh g -1 , The average discharge voltage is 1.08V, and it can be charged and discharged more than 3 times.

Embodiment 3

[0032]Others are as in Example 1.

[0033] With 5M aluminum trifluoromethanesulfonate aqueous solution as the electrolyte, the battery operates at 50mA g -1 Charge and discharge at a constant current, the charge and discharge voltage range is 0.5–1.7V, and the discharge specific capacity is 137mAh g -1 , the average discharge voltage is 1.38V, and the remaining specific capacity is 64mAh g after 10 charge-discharge cycles -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com