A kind of preparation method of acid-base double-layer core-shell nanotube/speek composite proton exchange membrane

A proton exchange membrane and nanotube technology, which is applied in the field of nanocomposite membrane preparation, can solve the problems of easy water loss and poor mechanical properties, and achieve good dimensional stability, moderate water absorption and swelling, and high proton conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] step 1)

[0049] PEEK was selected as the matrix material, and the reaction conditions were regulated by the control variable method to prepare SPEEK with a suitable sulfonation degree. The specific steps are: weigh 7g of PEEK pellets, slowly dissolve it in 125ml of concentrated sulfuric acid at room temperature, after complete dissolution, keep it in a water bath at 50°C for 8 hours, slowly pour the reaction solution into the ice-water mixture, and wash the product with water After reaching neutrality, air-dry for 48 hours, then vacuum-dry at 60°C for 24 hours to obtain sulfonated PEEK.

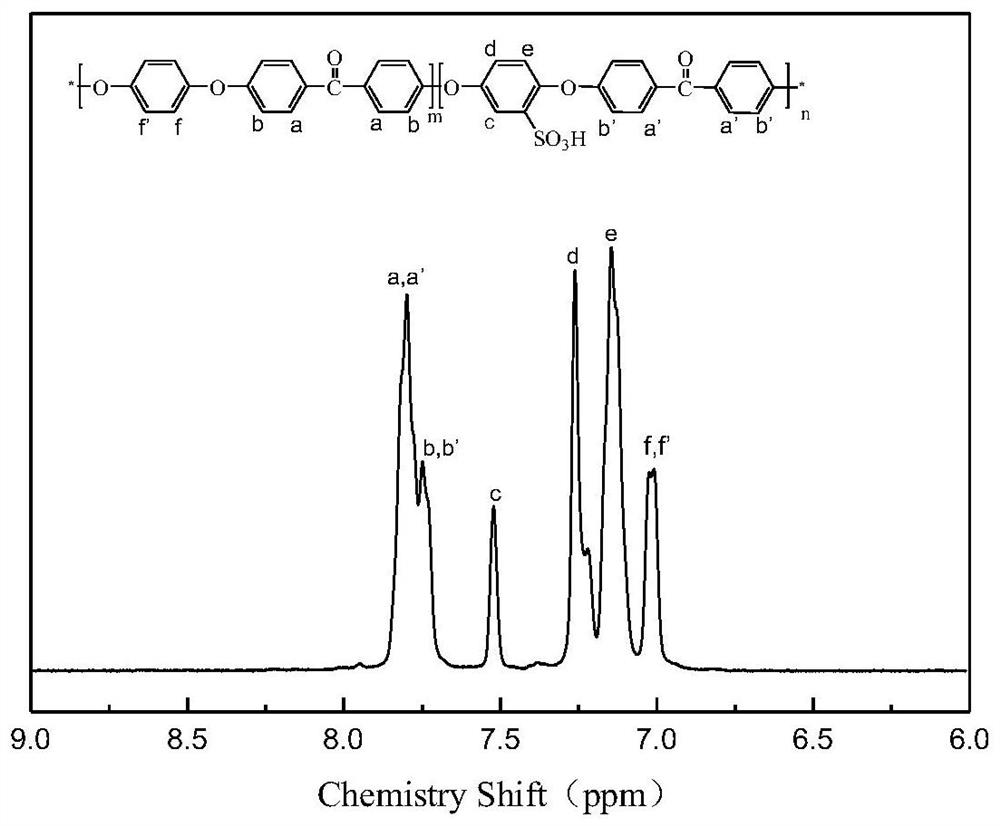

[0050] In order to measure the sulfonation degree of SPEKK, the sulfonation degree of SPEEK was calculated by NMR method. The hydrogens corresponding to different positions on the SPEEK structural unit are respectively represented by H a , H a ’, H b , H b’ , H c , H d , H d’ ,H e , H f , H f’ To identify. Each repeating unit has 12 hydrogens, H c The position on the benz...

Embodiment 2

[0065] Doping amount is the preparation of 5% acid-base double-layer core-shell nanotube / SPEEK composite proton exchange membrane, its implementation steps are the same as step (5) in example 1, the difference is that 0.016gDSNT-A@ B was changed to 0.04g DSNT-A@B and added to DMF (5mL), the prepared composite film was called SPEEK / DSNT-A@B-5, and the average thickness of the obtained composite film was 60 to 80 μm.

Embodiment 3

[0067] The doping amount is the preparation of acid-base double-layer core-shell nanotube / SPEEK composite proton exchange membrane. gDSNT-A@B was added to DMF (5 mL), and the prepared composite film was called SPEEK / DSNT-A@B-8, and the average thickness of the obtained composite film was 60 to 80 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com