Layered and batch type seed coating machine

A coating machine, batch technology, applied in the direction of seed coating/seed dressing, swirl device, etc., can solve the problems of endangering the health of operators, increasing the risk of dust explosion, polluting the workshop environment, etc., and achieving good atomization effect. , The equipment has the effect of good stability and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

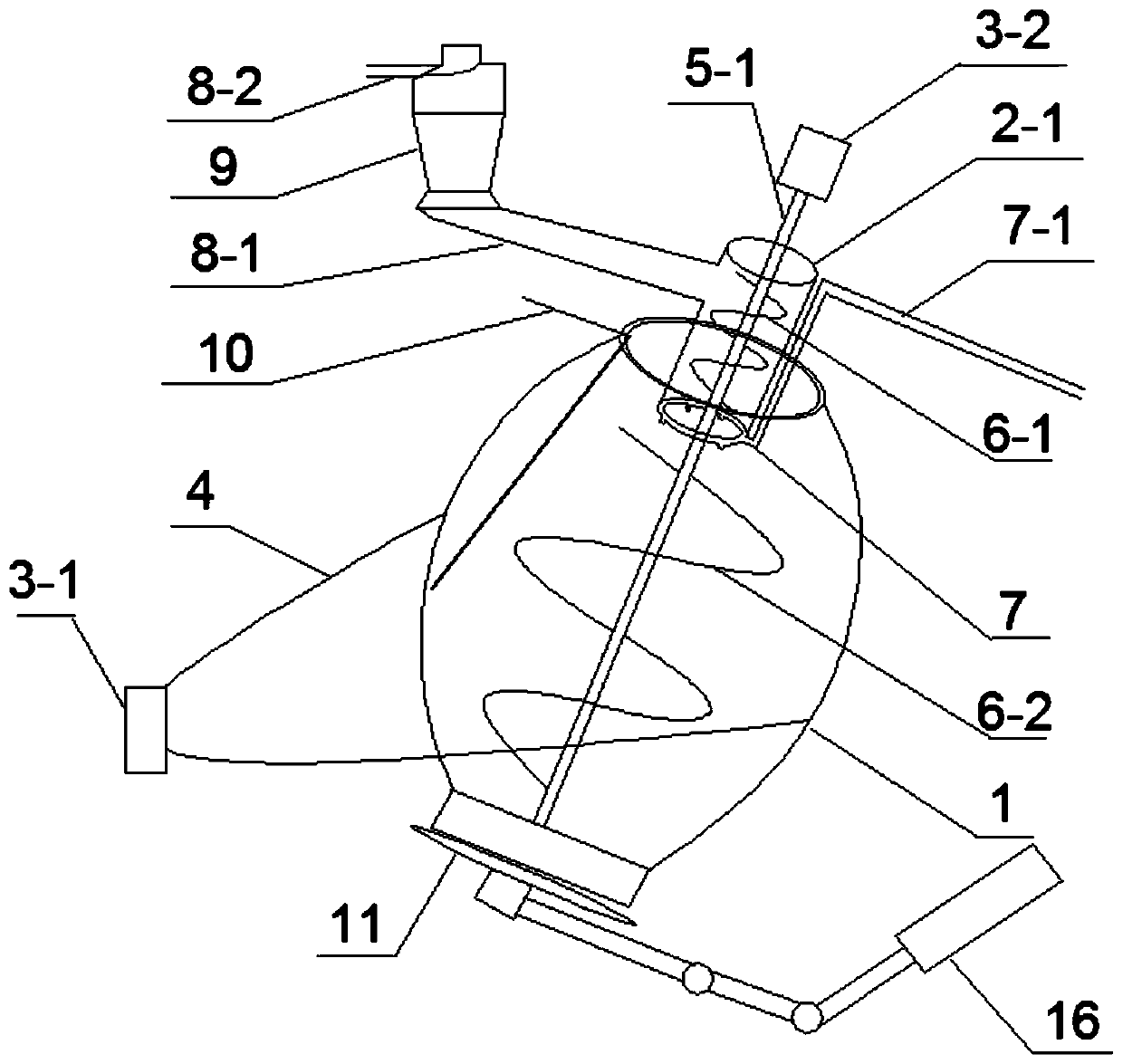

[0023] Embodiment 1, refer to figure 1 and Figure 4 , figure 1 It is a schematic structural view of a layered batch type seed coating machine of the present invention, Figure 4 It is a structural schematic diagram of the annular medicine liquid pipe of the present invention. The present invention is a layered batch type seed coating machine, which includes a layered batch type seed coating machine, which includes a coating chamber 1, and is characterized in that: it also includes a first Powder chamber 2-1, first motor 3-1, power wheel 3-2, V-belt 4, first rotating shaft 5-1, first auger piece 6-1, second auger piece 6-2, Annular liquid medicine pipe 7, medicine feeding pipe 7-1, first powder conveying pipe 8-1, Sacron dust collector 9, discharge door 11; the first powder chamber is set at the opening of the upper end of the coating chamber 1 2-1, and the lower end of the first powder chamber 2-1 extends into the coating chamber 1, and a first rotating shaft 5-1 is set in...

Embodiment 2

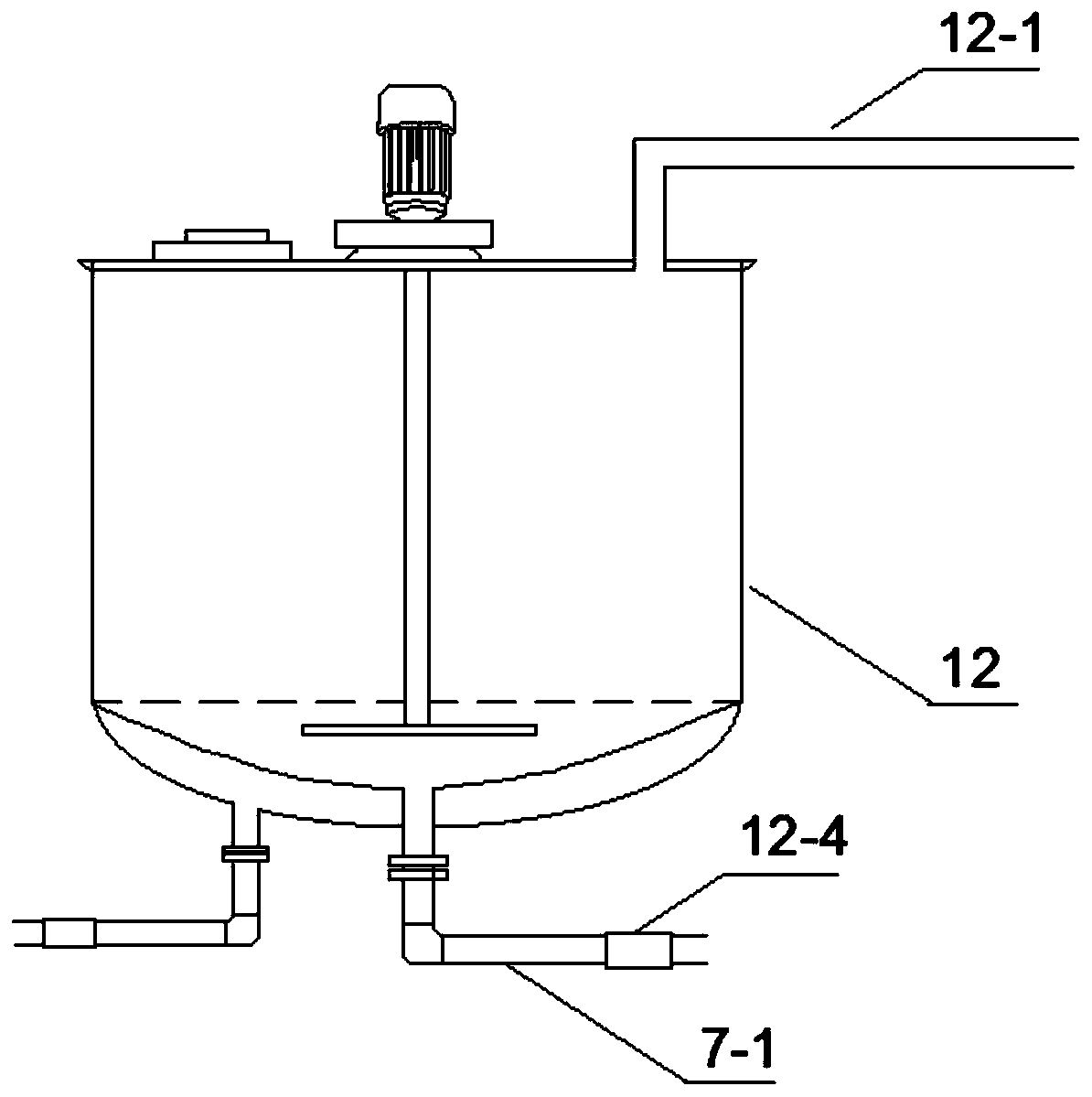

[0028] Embodiment 2, refer to figure 1 and figure 2 , figure 1 It is a schematic structural view of a layered batch type seed coating machine of the present invention, figure 2It is a schematic diagram of the structure of the liquid medicine mixing tank of the present invention. The present invention is a layered batch type seed coating machine, and the end of the medicine feeding pipe 7-1 far away from the annular medicine liquid pipe 7 is connected with a medicine liquid stirring tank 12, and the The medicinal liquid metering barrel is connected in series between the medicinal liquid stirring barrel 12 and the annular medicinal liquid pipe 7 . A valve 12-4 is provided between the liquid medicine mixing barrel 12 and the liquid medicine metering barrel, and the valve 12-4 is electrically connected to the PLC control system, and the upper part of the medicine liquid stirring barrel 12 is provided with a compressed air inlet 12-1.

[0029] In embodiment 1, the medicinal l...

Embodiment 3

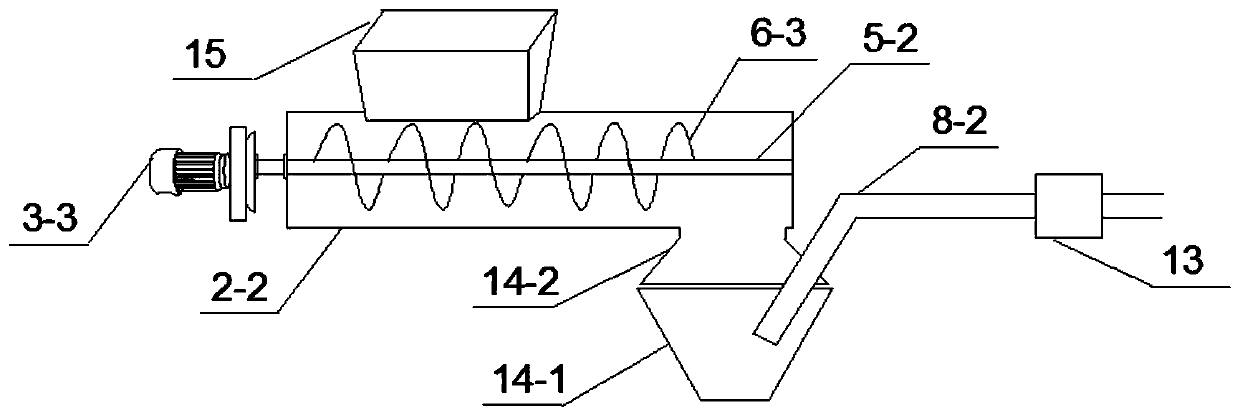

[0032] Embodiment 3, refer to figure 1 and image 3 , figure 1 It is a schematic structural view of a layered batch type seed coating machine of the present invention, image 3 It is a schematic structural diagram of the powder conveying system of the present invention, and the present invention is a layered batch seed coating machine.

[0033] The end of the Shacron dust collector 9 away from the first powder delivery pipe 8-1 is connected to the second powder delivery pipe 8-2, and the pneumatic conveyor 13 is connected in series on the second powder delivery pipe 8-2; The port of the second powder conveying pipe 8-2 is placed in the first funnel 14-1, the lower end of the first funnel 14-1 is closed, the upper end is provided with a cover 14-2, and the upper end of the cover 14-2 is open And it is connected with the second powder chamber 2-2.

[0034] The second powder chamber 2-2 is placed horizontally, and there is a second rotating shaft 5-2 inside, one end of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com